Tlhaloso ea Sehlahisoa

Liphaephe tsa tšepe tse potolohang, tse tsejoang hape e le liphaephe tsa tšepe tse helical submerged arc-welded (HSAW), ke mofuta oa phaephe ea tšepe e khetholloang ka mokhoa oa tsona o ikhethang oa tlhahiso le thepa ea sebopeho. Liphaephe tsena li sebelisoa haholo liindastering tse fapaneng ka lebaka la matla a tsona, ho tšoarella le ho ikamahanya le maemo. Tlhaloso e qaqileng ea liphaephe tsa tšepe tse potolohang ke ena:

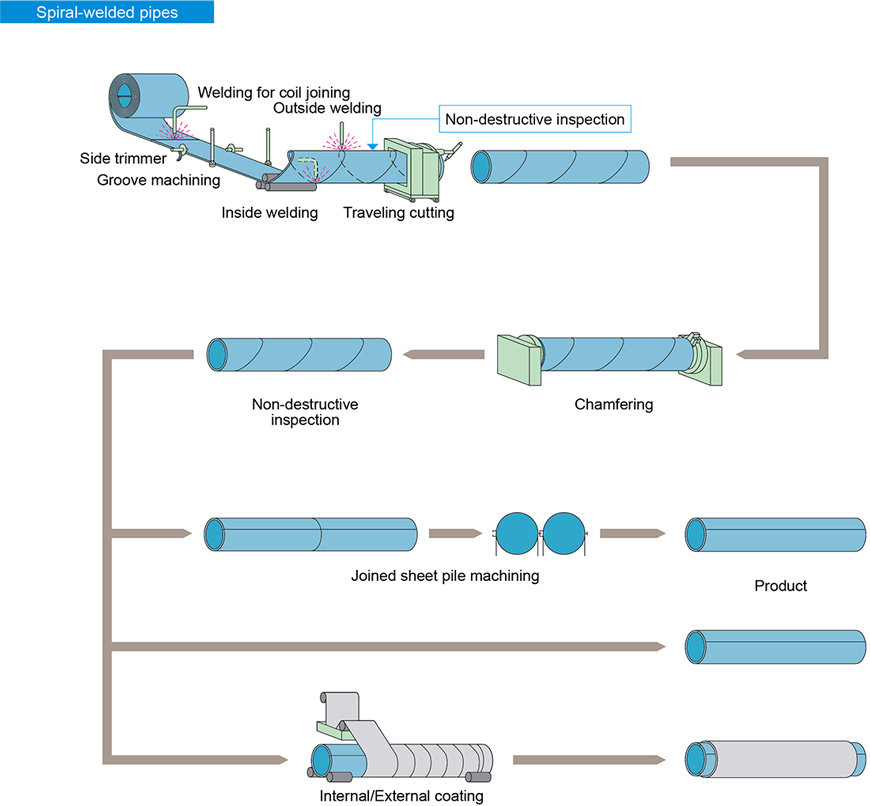

Mokhoa oa Tlhahiso:Liphaephe tsa tšepe tse potolohang li hlahisoa ka mokhoa o ikhethang o kenyeletsang tšebeliso ea khoele ea moqomo oa tšepe. Moqomo o a phutholoha 'me oa etsoa ka sebopeho sa moqomo, ebe oa tjheseletsa ho sebelisoa mokhoa oa ho welding oa arc o ka tlas'a metsi (SAW). Ts'ebetso ena e fella ka moalo o tsoelang pele, o helical bolelele ba phaephe.

Moralo oa Meaho:Sehokelo sa helical sa liphaephe tsa tšepe tse potolohang se fana ka matla a tlhaho, e leng se etsang hore li lokele ho mamella meroalo le likhatello tse phahameng. Moralo ona o netefatsa kabo e ts'oanang ea khatello 'me o ntlafatsa bokhoni ba phaephe ba ho hanela ho kobeha le ho fetoha.

Boholo ba Boholo:Liphaephe tsa tšepe tse potolohang li tla ka bophara bo fapaneng (ho fihlela ho lisenthimithara tse 120) le botenya, e leng se lumellang ho tenyetseha lits'ebetsong tse fapaneng. Li fumaneha hangata ka bophara bo boholo ha li bapisoa le mefuta e meng ea liphaephe.

Likopo:Liphaephe tsa tšepe tse potolohang li sebelisoa liindastering tse fapaneng tse kang oli le khase, phepelo ea metsi, kaho, temo le nts'etsopele ea meralo ea motheo. Li loketse lits'ebetso tse kaholimo ho mobu le tse ka tlas'a lefatše.

Khanyetso ea ho Sila:Ho ntlafatsa bophelo bo bolelele, liphaephe tsa tšepe tse potolohang hangata li feta kalafong ea ho thibela ho bola. Tsena li ka kenyelletsa lipente tsa ka hare le tsa kantle, tse kang epoxy, polyethylene le zinc, tse sireletsang liphaephe linthong tsa tikoloho le linthong tse senyang.

Melemo:Liphaephe tsa tšepe tse potolohang li fana ka melemo e 'maloa, ho kenyeletsoa le bokhoni bo phahameng ba ho jara moroalo, katleho ea litšenyehelo bakeng sa liphaephe tse bophara bo boholo, bonolo ba ho li kenya, le ho hanyetsa ho fetoha ha tsona. Moralo oa tsona o kang oa helical o boetse o thusa ho ntsha metsi ka katleho.

LongitudinalVSSekoele:Liphaephe tsa tšepe tse potolohang li khetholloa ho liphaephe tse kopantsoeng ka bolelele ka mokhoa oa tsona oa tlhahiso. Leha liphaephe tse telele li thehoa le ho kopantsoe bolelele ba phaephe, liphaephe tse potolohang li na le moalo o helical o entsoeng nakong ea tlhahiso.

Taolo ea Boleng:Mekhoa ea tlhahiso le taolo ea boleng e bohlokoa haholo ho hlahiseng liphaephe tsa tšepe tse spiral tse tšepahalang. Litekanyetso tsa ho tjheseletsa, jiometri ea liphaephe, le mekhoa ea liteko li hlahlojoa ka hloko ho netefatsa ho latela maemo le litlhaloso tsa indasteri.

Maemo le Litlhaloso:Liphaephe tsa tšepe tse potolohang li etsoa ho latela maemo a machaba le a indasteri a ikhethileng joalo ka API 5L, ASTM, EN, le a mang. Maemo ana a hlalosa thepa ea thepa, mekhoa ea tlhahiso le litlhoko tsa liteko.

Ka bokhutšoanyane, liphaephe tsa tšepe tse potolohang ke tharollo e sebetsang ka ho fetisisa le e tšoarellang bakeng sa liindasteri tse fapaneng. Ts'ebetso ea tsona e ikhethang ea tlhahiso, matla a tlhaho, le ho fumaneha ha tsona ka boholo bo fapaneng li tlatsetsa ts'ebelisong ea tsona e pharaletseng meralong ea motheo, lipalangoang, matla, kaho ea likou le tse ling. Khetho e nepahetseng, taolo ea boleng, le mehato ea tšireletso ea mafome li bapala karolo ea bohlokoa ho netefatseng ts'ebetso ea nako e telele ea liphaephe tsa tšepe tse potolohang.

Litlhaloso

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Kereiti C250, Kereiti C350, Kereiti C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

| Bophara(mm) | Botenya ba lebota (mm) | |||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| 219.1 | ● | ● | ● | ● | ||||||||||||||||

| 273 | ● | ● | ● | ● | ● | |||||||||||||||

| 323.9 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 325 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 355.6 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 377 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 406.4 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 426 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 457 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 478 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 508 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 529 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 630 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 711 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 720 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 813 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 920 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1420 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1620 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 1820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2500 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2540 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 3000 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

Mamello ea Bophara ba Kantle le Botenya ba Lebota

| E tloaelehileng | Mamello ea 'Mele oa Pipe | Mamello ea Bofelo ba Pipe | Mamello ea Botenya ba Lebota | |||

| Bophara ba kantle | Mamello | Bophara ba kantle | Mamello | |||

| GB/T3091 | OD≤48.3mm | ≤±0.5 | OD≤48.3mm | - | ≤±10% | |

| 48.3 | ≤±1.0% | 48.3 | - | |||

| 273.1 | ≤±0.75% | 273.1 | -0.8~+2.4 | |||

| OD>508mm | ≤±1.0% | OD>508mm | -0.8~+3.2 | |||

| GB/T9711.1 | OD≤48.3mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3 | ≤±0.75% | OD≤273.1mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% | |

| 508 | ≤±1.0% | OD≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| OD>941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | 60 | ± 0.75%D~±3mm | 60 | ± 0.5%D~±1.6mm | 4mm | ±12.5%T~±15.0%T |

| 610 | ± 0.5%D~±4mm | 610 | ± 0.5%D~±1.6mm | Boima ba 'mele≥25mm | -3.00mm~+3.75mm | |

| OD> 1430mm | - | OD> 1430mm | - | - | -10.0%~+17.5% | |

| SY/T5037 | OD<508mm | ≤±0.75% | OD<508mm | ≤±0.75% | OD<508mm | ≤±12.5% |

| OD≥508mm | ≤±1.00% | OD≥508mm | ≤±0.50% | OD≥508mm | ≤±10.0% | |

| API 5L PSL1/PSL2 | OD<60.3 | -0.8mm~+0.4mm | OD≤168.3 | -0.4mm~+1.6mm | Boima ba 'mele≤5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3 | ≤±1.6mm | 5.0 | ≤±0.1T | |

| 168.3 | ≤±0.75% | 610 | ≤±1.6mm | T≥15.0 | ≤±1.5 | |

| 610 | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% | |

| OD≥114.3 | -0.5%~1.0% | OD≥114.3 | -0.5%~1.0% | ≤-12.5% | ||

| ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| DN mm | NB Senthimithara | OD mm | SCH40S mm | SCH5S mm | SCH10S mm | SCH10 mm | SCH20 mm | SCH40 mm | SCH60 mm | XS/80S mm | SCH80 mm | SCH100 mm | SCH120 mm | SCH140 mm | SCH160 mm | SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| DN 1000mm le ho feta Bophara ba lebota la phaephe Bophahamo ba 25mm | ||||||||||||||||

Maemo le Kereiti

| E tloaelehileng | Likereiti tsa Tšepe |

| API 5L: Tlhaloso bakeng sa Pipe ea Mohala | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Tlhaloso e Tloaelehileng bakeng sa Liqubu tsa Liphaephe tsa Tšepe tse Welded le tse se nang Seamless | GR.1, GR.2, GR.3 |

| EN 10219-1: Likarolo tse nang le sekoti tse entsoeng ka mokhoa o batang tsa litšepe tse seng tsa motsoako le tsa lijo-thollo tse ntle | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Likarolo tse Chesang tse Felletseng tsa Meaho tse sa Tšoarellang le tsa Litšepe tse Ntle tsa Koro | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Phaephe, Tšepe, E Ntšo le e Chesang, e Koahetsoeng ka Zinki, e Welded le e se nang Seamless | GR.A, GR.B |

| EN 10217: Liphaephe tsa Tšepe tse Welded bakeng sa Merero ea Khatello | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Liphaephe tsa Tšepe tse Welded le Liphaephe | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Tekanyetso ea Australia/New Zealand bakeng sa Likarolo tsa Tšepe ea Meaho e entsoeng ka Batang | Sehlopha sa C250, Sehlopha sa C350, Sehlopha sa C450 |

| GB/T 9711: Liindasteri tsa Petroleum le Khase ea Tlhaho - Pipe ea Tšepe bakeng sa Liphaephe | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| AWWA C200: Pipe ea Metsi ea Tšepe ea Li-inchi tse 6 (150 mm) le e Khōlō | Tšepe ea Khabone |

Mokhoa oa Tlhahiso

Taolo ea Boleng

● Ho hlahloba thepa e tala

● Tlhahlobo ea Lik'hemik'hale

● Teko ea Mekaniki

● Tlhahlobo ea Pono

● Tlhahlobo ea Tekanyo

● Teko ea ho Kobeha

● Teko ea Tšusumetso

● Teko ea ho Sila ha li-intergranular

● Tlhahlobo e sa Senyeheng (UT, MT, PT)

● Tšoaneleho ea Tsamaiso ea ho Chesa

● Tlhahlobo ea Sebopeho se Senyenyane

● Teko ea ho Chesa le ho Fokotsa

● Teko ea ho tiea

● Teko ea Khatello

● Teko ea Metalography

● Teko ea ho senyeha

● Teko ea Hona Joale ea Eddy

● Tlhahlobo ea ho Penta le ho Koahela

● Tlhahlobo ea Litokomane

Tšebeliso le Tšebeliso

Liphaephe tsa tšepe tse potolohang lia tenyetseha 'me li sebelisoa haholo indastering e fapaneng ka lebaka la litšobotsi le melemo ea tsona e ikhethang. Li thehoa ka ho kopanya likhoele tsa tšepe ka helical ho etsa phaephe e nang le moalo o potolohang o tsoelang pele. Mona ke lits'ebeliso tse tloaelehileng tsa liphaephe tsa tšepe tse potolohang:

● Tsamaiso ea Metsi: Liphaephe tsena li tsamaisa metsi, oli le khase ka katleho libakeng tse telele ka har'a liphaephe ka lebaka la ho hahoa ha tsona ka mokhoa o se nang sekoli le matla a tsona a phahameng.

● Oli le Khase: Li bohlokoa bakeng sa liindasteri tsa oli le khase, li tsamaisa oli e tala, khase ea tlhaho le lihlahisoa tse hloekisitsoeng, li sebeletsa litlhoko tsa lipatlisiso le kabo.

● Ho bokella: Liqubu tsa motheo mererong ea kaho li tšehetsa meroalo e boima mehahong e kang mehaho le marokho.

● Tšebeliso ea Sebopeho: Li sebelisoa meralong ea kaho, likholomong le litšehetsong, ho tšoarella ha tsona ho tlatsetsa botsitsong ba sebopeho.

● Di-culvert le Di-drainage: Di sebediswa ditsamaisong tsa metsi, ho hanyetsa mafome le dikahare tse boreledi di thibela ho kwala le ho ntlafatsa phallo ya metsi.

● Mechini ea ho Tsamaisa Liphaephe: Tlhahisong le temong, liphaephe tsena li fana ka litharollo tse theko e tlaase le tse tiileng bakeng sa likarolo.

● Metsing le Libakeng Tse Ling: Bakeng sa libaka tse thata, li sebelisoa liphaepheng tse ka tlas'a metsi, lipolatefomong tse lebōpong la leoatle le kahong ea li-jetty.

● Merafo: Li tsamaisa thepa le lerōle mesebetsing e boima ea merafo ka lebaka la kaho ea tsona e tiileng.

● Phepelo ea Metsi: E loketse liphaephe tse bophara bo boholo lits'ebetsong tsa metsi, e tsamaisang metsi a mangata ka katleho.

● Mekhoa ea Geothermal: E sebelisoa mererong ea matla a geothermal, e sebetsana le phetiso ea mokelikeli o sa cheseng mocheso lipakeng tsa matamo le lifeme tsa motlakase.

Tsela e feto-fetohang ea liphaephe tsa tšepe tse potolohang, hammoho le matla a tsona, ho tšoarella le ho ikamahanya le maemo, li li etsa karolo ea bohlokoa liindastering le lits'ebetsong tse fapaneng.

Ho paka le ho Romela

Pakete:

Ts'ebetso ea ho paka liphaephe tsa tšepe tse potolohang e kenyelletsa mehato e 'maloa ea bohlokoa ho netefatsa hore liphaephe li sirelelitsoe ka ho lekaneng nakong ea lipalangoang le polokelo:

● Ho Kopanya Liphaephe: Liphaephe tsa tšepe tse potolohang hangata li kopanngoa hammoho ho sebelisoa marapo, mabanta a tšepe, kapa mekhoa e meng ea ho tiisa ka thata. Ho kopanya ho thibela liphaephe ka bomong ho tsamaea kapa ho fetoha ka har'a sephutheloana.

● Tšireletso ea Pheletso ea Phaephe: Likoahelo tsa polasetiki kapa likoahelo tse sireletsang li beoa lipheletsong ka bobeli tsa liphaephe ho thibela tšenyo lipheletsong tsa liphaephe le bokaholimo ba ka hare.

● Ho Thibela Metsi: Liphaephe li phutheloa ka thepa e sa keneleng metsi, joalo ka lipampiri tsa polasetiki kapa liphutheloana, ho li sireletsa mongobo nakong ea lipalangoang, haholo-holo likepeng tsa kantle kapa tsa likepe.

● Ho koahela: Lisebelisoa tse ling tsa ho koahela, tse kang lintho tse kenngoang ka foam kapa thepa ea ho boloka, li ka eketsoa lipakeng tsa liphaephe kapa libakeng tse kotsing ho monya litšisinyeho le ho thothomela.

● Ho ngolwa ha mabitso: Sephutheloana se seng le se seng se ngolwa ka tlhahisoleseding ya bohlokwa, ho kenyeletswa le ditlhaloso tsa phaephe, boholo, bongata le moo e yang teng. Sena se thusa ho hlwaya le ho tshwara dintho habonolo.

Ho tsamaisa ka sekepe:

● Ho romela liphaephe tsa tšepe tse potolohang ho hloka moralo o hlokolosi ho netefatsa hore lipalangoang li sireletsehile ebile li sebetsa hantle:

● Mokhoa oa Lipalangoang: Khetho ea mokhoa oa lipalangoang (tsela, terene, leoatle, kapa moea) e itšetlehile ka lintlha tse kang sebaka, potlako, le phihlello ea moo u eang teng.

● Ho kenya liphaephe ka har'a lijana tse tloaelehileng tsa ho romela thepa kapa lijana tse khethehileng tse nang le li-rack tse bataletseng. Ho kenya liphaephe ka har'a lijana ho sireletsa liphaephe ho tsoa likarolong tse ka ntle 'me ho fana ka tikoloho e laoloang.

● Ho tiisa: Liphaephe li tiisoa ka har'a lijana ho sebelisoa mekhoa e loketseng ea ho li tiisa, joalo ka ho li tiisa, ho li thibela le ho li tlama. Sena se thibela motsamao le ho fokotsa kotsi ea tšenyo nakong ea ho tsamaea.

● Litokomane: Litokomane tse nepahetseng, ho kenyeletsoa le li-invoice, manane a ho paka, le li-manifest tsa thomello, li lokisetsoa merero ea ho hlakola lekhetho le ho le latela.

● Inshorense: Inshorense ea thepa hangata e fumanoa ho koahela tahlehelo kapa tšenyo e ka bang teng nakong ea lipalangoang.

● Tlhokomelo: Nakong eohle ea ts'ebetso ea thomello, liphaephe li ka lateloa ho sebelisoa GPS le litsamaiso tsa ho latela ho netefatsa hore li tseleng e nepahetseng le kemisong e nepahetseng.

● Ho Finyella Lekgetho la Meedi: Ho fanoe ka ditokomane tse nepahetseng ho nolofatsa ho finyella lekgetho la meedi ka bokgabane koung kapa moeding wa sebaka seo o yang ho sona.

Qetello:

Ho paka le ho romela liphaephe tsa tšepe tse potolohang ka nepo ho bohlokoa ho boloka boleng le botšepehi ba liphaephe nakong ea lipalangoang. Ho latela mekhoa e metle ea indasteri ho netefatsa hore liphaephe li fihla moo li eang teng li le boemong bo botle, li loketse ho kenngoa kapa ho sebetsoa hape.