Kakaretso ea Sehlahisoa

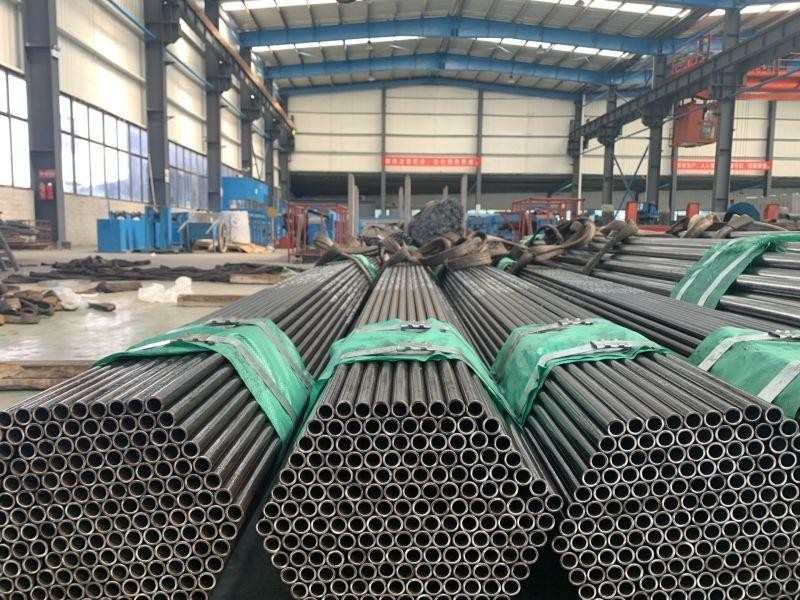

Womic Steel ke moetsi ea ka sehloohong oaEN 10305-li-tube tsa tšepe tse se nang sekoli tse netefalitsoeng, tse etselitsoeng ho nepahala, matla le ho tšoarella lits'ebetsong tse fapaneng tsa indasteri. Li-tube tsa rona tsa tšepe tse se nang sekoli li entsoe ho fihlela maemo a thata ka ho fetisisa a machaba, li fana ka ts'ebetso e ntle ka ho fetisisa bakeng sa litsamaiso tsa lipalangoang tsa mechini, tsa sebopeho le tsa metsi. Ho tloha boenjiniere ba likoloi ho isa ho li-cylinder tsa hydraulic, Womic Steel e netefatsa hore tube e 'ngoe le e 'ngoe e entsoe ka bokhabane, e netefatsang boleng bo ikhethang le ts'epo.

Ea ronaLiphaephe tsa tšepe tse se nang mohele tsa EN 10305li loketse lits'ebetso tse matla tse hlokang litekanyo tse nepahetseng, thepa e ntle ea mechini, le ho hanyetsa ka matla ho tsofala le ho bola. Li-tube tsena li sebelisoa liindastering tse ngata, ho kenyeletsoa likoloi, mechini, lipalangoang tsa metsi le boenjiniere ba mechini, ho fana ka litharollo tse tšepahalang bakeng sa lits'ebetso tsa boenjiniere bo nepahetseng.

Mefuta ea Tlhahiso ea Li-Tube tsa Tšepe tse se Nang Mohele tsa EN 10305

Baetsi ba Womic SteelLiphaephe tsa tšepe tse se nang mohele tsa EN 10305ka boholo le litekanyo tse fapaneng, ho netefatsa hore e tenyetseha bakeng sa lits'ebetso tse fapaneng. Mefuta e tloaelehileng ea tlhahiso e kenyelletsa:

- Bophara ba Kantle (OD): 6 mm ho isa ho 406 mm

- Botenya ba Lebota (WT): 1 mm ho isa ho 18 mm

- Bolelele: Bolelele bo ikhethileng, hangata bo tloha ho limithara tse 6 ho isa ho tse 12, bo fumaneha ha moreki a kopa.

Lipeipi tsena li ka hlahisoa ka litlhoko tse itseng bakeng sa bophara, bolelele le botenya ba lebota bo ikhethileng ho latela litlhaloso tsa bareki le litlhoko tsa projeke.

Mamello ea Lipeipi tsa Tšepe tse se Nang Mohele tsa EN 10305

Tšepe ea WomicLiphaephe tsa tšepe tse se nang mohele tsa EN 10305li etsoa ka ho tsepamisa maikutlo ho nepahaleng. Re netefatsa mamello e latelang bakeng sa lihlahisoa tsa rona

| Paramethara | Mamello |

| Bophara ba Kantle (OD) | ± 0.01 mm |

| Botenya ba Lebota (WT) | ± 0.1 mm |

| Ho ba le ovalite (Boemo bo bonyenyane) | 0.1 mm |

| Bolelele | ± 5 mm |

| Ho otloloha | Boholo 0.5 mm ka mithara |

| Qetello ea Bokaholimo | Ho ya ka tlhaloso ya moreki (hangata: Oli e lwantshang mafome, Ho maneha ka thata ha Chrome, Ho maneha ka chromium ya nikeli, kapa ho maneha tse ding) |

| Bolelele ba Lipheletso | ± 1° |

Maemo a ho Romela a Li-Tube tsa Tšepe tse se Nang Mohele tsa EN 10305

Liphaephe li etsoa ka ho sebelisasetšoantšo se batangkapaho phutholoha ho batanglits'ebetso 'me li fanoa maemong a fapaneng a phano ho latela litlhoko tse ikhethileng tsa bareki. Tsena li kenyelletsa:

Tafole ea 1 — Maemo a ho tlisa

| Tlhophiso | Letšoaoa | Tlhaloso |

| Ho huloa ka serame / ho thata | +C | Ha ho phekolo ea ho qetela ea mocheso kamora ho hula serame sa ho qetela. |

| Ho huloa ka serame / bonolo | +LC | Kalafo ea ho qetela ea mocheso e lateloa ke setšoantšo se loketseng ho feta (phokotso e fokolang ea sebaka). |

| Ho huloa ke serame le khatello ea maikutlo e imolloang | +SR | Kamora ho taka ho qetela ka serame, lipeipi li imolloa khatellong moeeng o laoloang. |

| E koahetsoeng ka bonolo | +A | Kamora ho taka ho qetela ka serame, lipeipi li koaheloa ka bonolo sepakapakeng se laoloang. |

| E tloaelehileng | +N | Kamora ho hula ha ho qetela ka serame, lipeipi lia tloaeleha ka sepakapaka se laoloang. |

| a: Ho ya ka EN10027–1. | ||

EN 10305 Li-Tube tsa Tšepe tse se Nang Mohele Sebopeho sa Lik'hemik'hale

TheEN 10305Lipeipi li etsoa ka limaraka tsa tšepe tsa boleng bo holimo. Ka tlase ke kakaretso ea limaraka tse tloaelehileng tsa thepa le metsoako ea tsona ea lik'hemik'hale:

Tafole ea 2 — Sebopeho sa lik'hemik'hale (tlhahlobo ea cast)

| Sehlopha sa tšepe | % ka boima | ||||||

| Lebitso la tšepe | Tšepe | C | Si | Mn | P | Sa | Alkakaretsob |

| nomoro | |||||||

| E215 | 1.0212 | 0,10 | 0,05 | 0,70 | 0,025 | 0,025 | 0,025 |

| E235 | 1.0308 | 0,17 | 0,35 | 1,20 | 0,025 | 0,025 | 0,015 |

| E355 | 1.0580 | 0,22 | 0,55 | 1,60 | 0,025 | 0,025 | 0,020 |

| Dikarolo ha di a qotswa tafoleng ena (empa sheba mongolo o botlaaseng ba leqepheb) e ke ke ea eketsoa ka boomo tšepeng ntle le tumellano ea moreki, ntle le likarolo tse ka eketsoang ka sepheo sa ho tlosa oxidation le/kapa ho tlama naetrojene. Mehato eohle e loketseng e tla nkoa ho thibela ho eketsoa ha likarolo tse sa batleheng ho tsoa linthong tse lahlehileng kapa thepa e 'ngoe e sebelisoang ts'ebetsong ea ho etsa tšepe. | |||||||

| a Sheba khetho ea 2. b Tlhokahalo ena ha e sebetse ha feela tshepe e na le bongata bo lekaneng ba dielemente tse ding tse tlamang naetrojene, tse kang Ti, Nb kapa V. Haeba ho ekeditswe, dikahare tsa dielemente tsena di tla tlalehwa tokomaneng ya tlhahlobo. Ha o sebedisa titanium, moetsi o tla netefatsa hore (Al + Ti/2) ≥ 0,020. | |||||||

Khetho ea 2: Bakeng sa mekgahlelo ea tšepe E235 le E355, sebabole se laoloang sa 0,015% ho isa ho 0,040% se hlalositsoe ho tšehetsa ho sebetsa ha sona. Se tla fumanoa ka ho tsosolosa tšepe ka mor'a ho e tlosa ka ho feletseng kapa ka ho sebelisa mokhoa o fokolang oa oksijene.

Khetho ea 3: Sebopeho sa lik'hemik'hale sa sehlopha sa tšepe se boletsoeng e lokela ho ba se loketseng ho galvanizing e chesang (sheba mohlala, EN ISO 1461 kapa EN ISO 14713-2 bakeng sa tataiso).

Tafole ea 3 le Tafole ea A.2 li totobatsa ho kheloha ho lumelletsoeng ha tlhahlobo ea sehlahisoa ho tloha meeling e boletsoeng tlhahlobong ea cast e fanoeng Tafoleng ea 2 le Tafole ea A.1

Tafole ea 3 — Ho kheloha ho lumelletsoeng ha tlhahlobo ea sehlahisoa ho tsoa meeling e boletsoeng tlhahlobong ea cast e fanoeng Tafoleng ea 2

| Karolo | Boleng bo lekanyetsoang bakeng sa batšoantšisi | Ho kheloha ho lumelletsoeng ha tlhahlobo ea sehlahisoa |

| C | ≤0,22 | +0,02 |

| Si | ≤0,55 | +0,05 |

| Mn | ≤1,60 | +0,10 |

| P | ≤0,025 | +0,005 |

| S | ≤0,040 | ± 0,005 |

| Al | ≥0,015 | -0,005 |

EN 10305 Li-Tube tsa Tšepe tse se Nang Mohele Thepa ea Mechini

Thepa ea mechini eaEN 10305Liphaephe tsa tšepe tse se nang moedi, tse lekanngoang mochesong oa kamore, ke tse latelang. Litekanyetso tsena li itšetlehile ka sehlopha sa tšepe le boemo ba ho tlisoa:

Tafole ea 4 — Thepa ea mechini mochesong oa kamore

| Sehlopha sa tšepe | Boleng bo tlase bakeng sa boemo ba ho pepaa | ||||||||||||

| +Cb | +LCb | +SR | +Ac | +N | |||||||||

| Tšepe | Tšepe | Rm | A | Rm | A | Rm | ReH | A | Rm | A | Rm | ReHd | A |

| lebitso | nomoro | MPa | % | MPa | % | MPa | MPa | % | MPa | % | MPa | MPa | % |

| E215 | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 ho isa ho 430 | 215 | 30 |

| E235 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 350 | 16 | 315 | 25 | 340 ho isa ho 480 | 235 | 25 |

| E355 | 1.058 | 640 | 4 | 580 | 7 | 580 | 450e | 10 | 450 | 22 | 490 ho isa ho 630 | 355 | 22 |

| Rm: matla a ho thapolla; ReH: matla a kotulo e phahameng (empa sheba 11.1); A: ho lelefala ka mora ho robeha. Bakeng sa matshwao a boemo ba ho pepa sheba Tafole ya 1 | |||||||||||||

| b Ho latela tekanyo ea mosebetsi o batang ho phethong ea ho qetela, matla a tlhahiso a ka batla a lekana le matla a ho thapolla. Bakeng sa merero ea lipalo, likamano tse latelang lia khothaletsoa: —bakeng sa boemo ba ho fihla +C: ReH≥0,8 Rm; —bakeng sa boemo ba ho isa +LC: ReH≥0,7 Rm. | |||||||||||||

| c Bakeng sa merero ea lipalo, kamano e latelang ea khothaletsoa: ReH≥0,5 Rm. | |||||||||||||

| d Bakeng sa lipeipi tse nang le bophara ba kantle ba ≤30mm le botenya ba lebota ≤3mm ReHBoleng bo tlase ba 10MPa bo ka tlase ho boleng bo fanoeng tafoleng ena. | |||||||||||||

| Bakeng sa lipeipi tse nang le bophara ba kantle> 160mm: ReH≥420MPa. | |||||||||||||

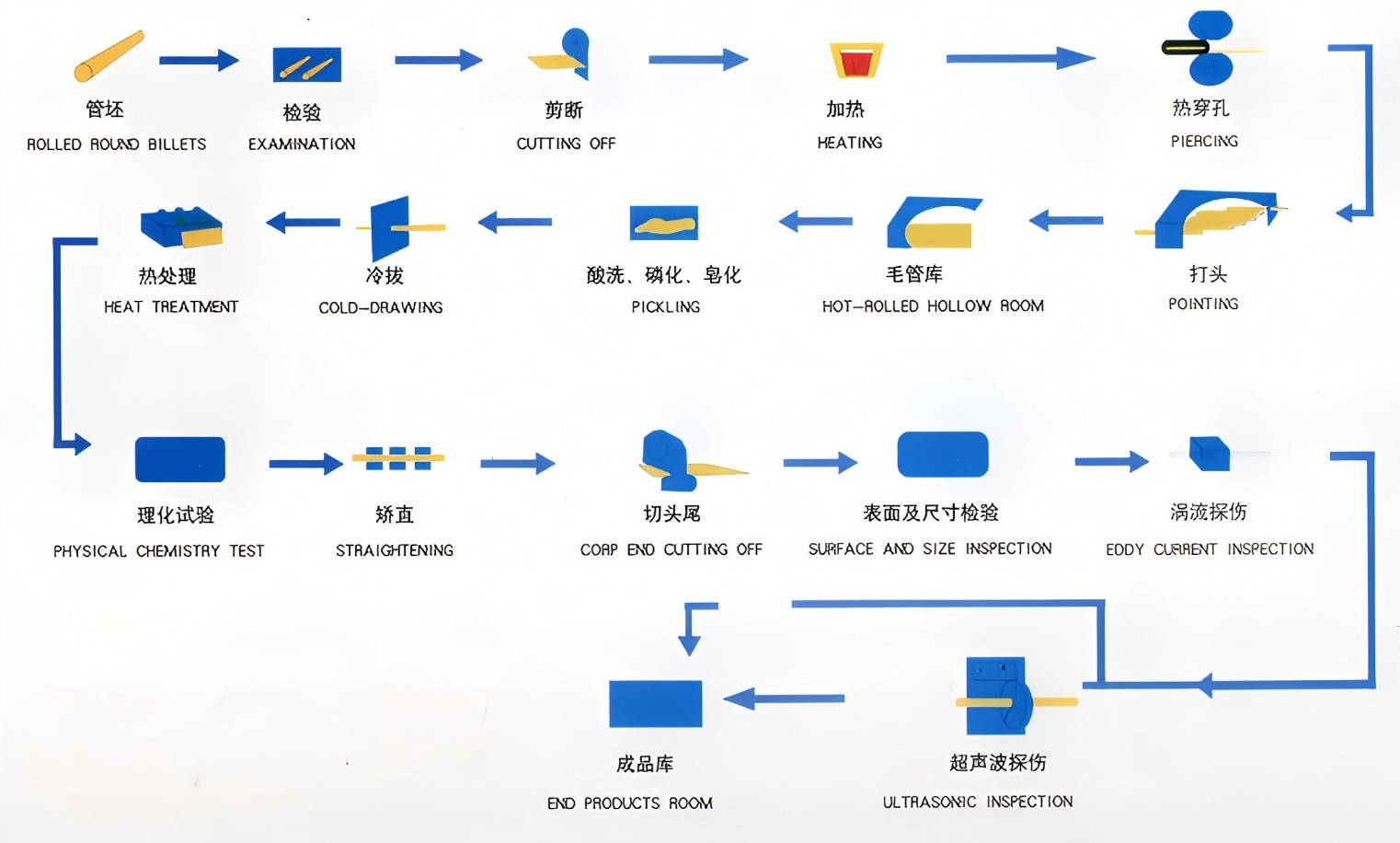

Ts'ebetso ea Tlhahiso ea Li-Tube tsa Tšepe tse se Nang Mohele tsa EN 10305

Womic Steel e sebelisa mekhoa e tsoetseng pele ea tlhahiso ho hlahisaLiphaephe tsa tšepe tse se nang mohele tsa EN 10305, ho netefatsa lihlahisoa tsa boleng bo holimo, tse entsoeng ka mokhoa o nepahetseng. Ts'ebetso ena e kenyelletsa mekhahlelo ea bohlokoa e latelang:

- Khetho ea Billet le Tlhahlobo:

Ts'ebetso ea tlhahiso e qala ka li-billet tsa tšepe tsa boleng bo holimo, tse hlahlobiloeng ka botlalo ho netefatsa ho tsitsa le ho lumellana le litlhaloso tsa thepa. - Ho futhumatsa le ho phunya:

Li-billet li futhumatsoa ho fihlela mochesong o motle ebe li phunngoa ho etsa tube e se nang letho, e li lokisetsang ho bōptjoa hape. - Ho Roller e Chesang:

Li-billet tse se nang letho li fetoloa ka ho tjhesa ho bopa phaephe, ho lokisa boholo ba sehlahisoa sa ho qetela. - Setšoantšo se batang:

Liphaephe tse phuthoang ka mocheso li huloa ka serame tlas'a maemo a laoloang ho fihlela bophara le botenya bo nepahetseng ba lebota. - Ho seha:

Kamora ho hula ka serame, lipeipi lia qhibilihisoa ho tlosa sekala sefe kapa sefe sa bokaholimo kapa likarolo tsa oxide, ho netefatsa bokaholimo bo hloekileng le bo boreleli. - Kalafo ea Mocheso:

Liphaephe tsena li sebelisoa lits'ebetsong tsa kalafo ea mocheso tse kang ho annealing, e leng se ntlafatsang thepa ea tsona ea mechini le ho netefatsa hore lia tšoana. - Ho otlolla le ho Seha:

Lipeipi li otlolohile 'me lia khaoloa ka bolelele bo hlokahalang, ho boloka ho lekana le ho nepahala. - Tlhahlobo le Teko:

Ho etsoa tlhahlobo e matla, ho kenyeletsoa le liteko tsa boholo, liteko tsa mechini, le liteko tse sa senyeheng (NDT), ho netefatsa maemo a boleng bo holimo ka ho fetisisa.

Teko le Tlhahlobo

Womic Steel e netefatsa maemo a holimo ka ho fetisisa a netefatso ea boleng le ho sala morao ka mekhoa e felletseng ea liteko bakeng saLiphaephe tsa tšepe tse se nang mohele tsa EN 10305Tsena di kenyeletsa:

- Tlhahlobo ea litekanyo:

Tekanyo ea bophara ba kantle, botenya ba lebota, bolelele, ovality le ho otloloha. - Teko ea Mechini:

E kenyeletsa liteko tsa ho tsitlella, liteko tsa tšusumetso, le liteko tsa ho thatafala ho netefatsa matla le ho thiba ho hlokahalang. - Teko e sa Senyeheng (NDT):

Teko ea hona joale ea Eddy ho lemoha liphoso tsa ka hare, teko ea ultrasound (UT) bakeng sa botenya ba lebota le botšepehi ba sebopeho. - Tlhahlobo ea Lik'hemik'hale:

Sebopeho sa thepa se netefatsoa ho sebelisoa mekhoa ea spectrographic ho netefatsa hore thepa e fihlela litlhoko tse hlokahalang. - Teko ea Hydrostatic:

Phaephe e etsoa liteko tsa khatello ea ka hare ho netefatsa hore e ka mamella khatello ea ts'ebetso ntle le ho hloleha.

Taolo ea Laboratori le Boleng

Womic Steel e sebetsa laboratori ea sejoale-joale e nang le lisebelisoa tse tsoetseng pele tsa liteko ho etsa liteko tse tebileng tsa boleng. Sehlopha sa rona sa botekgeniki se etsa liteko tsa kamehla sehlopheng se seng le se seng saLiphaephe tsa tšepe tse se nang mohele tsa EN 10305ho netefatsa hore ho latela maemo a tiileng a machaba. Re boetse re sebelisana 'moho le mekhatlo ea liteko ea mokha oa boraro ho fana ka netefatso e ikemetseng ea boleng ba liphaephe.

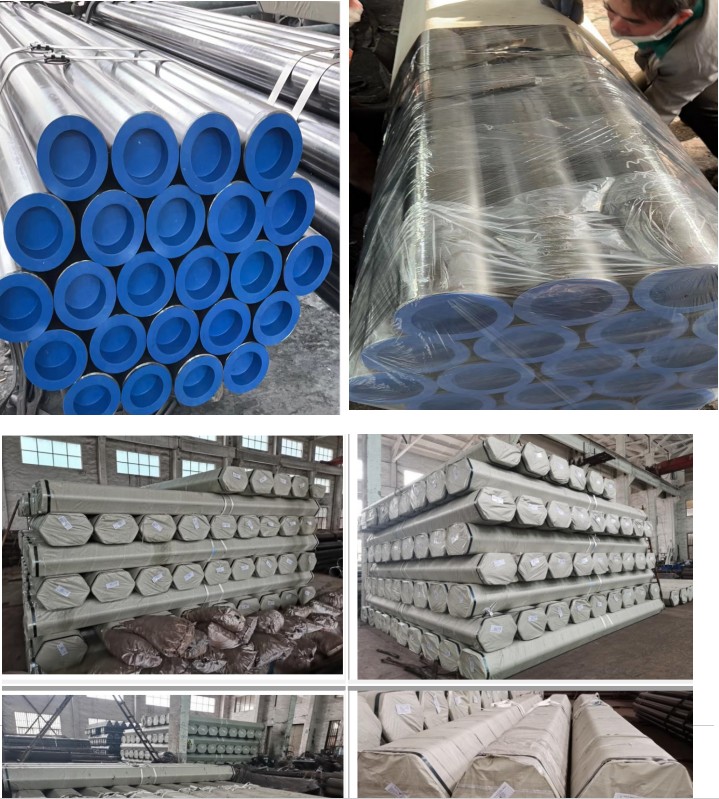

Sephutheloana

TheLiphaephe tsa tšepe tse se nang mohele tsa EN 10305li phuthetsoe ka hloko ho netefatsa hore li tsamaisoa le ho romelloa li sireletsehile. Liphutheloana li kenyelletsa:

- Sekoahelo se Sireletsang:

Chupu ka 'ngoe e koahetsoe ka lera le sireletsang khahlanong le mafome ho thibela mafome le oxidation nakong ea lipalangoang le polokelo. - Li-cap tsa ho qetela:

Likoahelo tsa polasetiki kapa tsa tšepe li sebelisoa lipheletsong ka bobeli tsa lipeipi ho thibela tšilafalo, mongobo, kapa tšenyo ea 'mele. - Ho kopanya:

Liphaephe li tlameletsoe hammoho ka mokhoa o sireletsehileng ka marapo a tšepe kapa lithapo tsa polasetiki ho boloka botsitso le ho thibela ho sutha nakong ea lipalangoang. - Ho phuthela ka bonolo:

Liphutheloana li phuthetsoe ka filimi ea ho nyenyefatsa ho sireletsa lipeipi lerōleng, litšila le lintho tse ling tse amang tikoloho. - Boitsebiso le ho Ngola Libibele:

Sephutheloana se seng le se seng se ngotswe ka dintlha tsa sehlahiswa, ho kenyeletswa le kereiti ya tshepe, boholo, nomoro ya sehlopha, bongata, le ditaelo dife kapa dife tse ikgethang tsa ho sebetsana le tsona.

Lipalangoang

Womic Steel e netefatsa hore ho tlatswa ha thepa lefatšeng ka bophara ka nako e nepahetseng le ka mokhoa o tšepahalangLiphaephe tsa tšepe tse se nang mohele tsa EN 10305ka mekhoa e latelang ea lipalangoang:

Thepa ea Leoatleng:

Bakeng sa thomello ea machaba, liphaephe li kenngoa ka har'a lijana kapa li-rack tse bataletseng 'me li romeloa sebakeng leha e le sefe lefatšeng ka bophara.

Lipalangoang tsa Terene le Litsela:

Bakeng sa thepa ea malapeng le ea libakeng tse ling, liphaephe li kenngoa ka mokhoa o sireletsehileng literakang kapa lijaneng tse bataletseng 'me li tsamaisoa ka tsela kapa ka terene.

Taolo ea Tlelaemete:

Haeba ho hlokahala, re ka lokisetsa lipalangoang tse laoloang ke boemo ba leholimo ho sireletsa lipeipi maemong a feteletseng a tikoloho.

Litokomane le Inshorense:

Litokomane tse felletseng tsa ho hlakola thepa ea lekgetho, ho e romella le ho e latela lia fanoa, 'me inshorense e ka lokisetsoa thepa ea machabeng ho itšireletsa khahlanong le tšenyo kapa tahlehelo e ka bang teng.

Melemo ea ho Khetha Tšepe ea Basali

Tlhahiso e Nepahetseng:

Re boloka taolo e tiileng hodima ditshebetso tsohle tsa tlhahiso ho fihlela mamello e nepahetseng ya boholo.

Ho iketsetsa:

Likhetho tse tenyetsehang bakeng sa bolelele ba lipeipi, mekhoa ea ho lokisa bokaholimo, le sephutheloana ho latela litlhaloso tsa bareki.

Teko e Felletseng:

Teko e matla e netefatsa hore phaephe e 'ngoe le e 'ngoe e fihlela litekanyetso tse hlokahalang tsa mechini, lik'hemik'hale le litekanyo.

Phano ea Lefatše ka Bophara:

Thomello e tšepahalang le e nakong, kae kapa kae moo projeke ea hau e leng teng.

Sehlopha se nang le boiphihlelo:

Baenjiniere le litsebi tse nang le boiphihlelo ba netefatsa boleng bo holimo ba tlhahiso le maemo a litšebeletso tsa bareki.

Qetello

Tšepe ea WomicLiphaephe tsa Tšepe tse se nang Mohele tsa EN 10305li etselitsoe ho fana ka matla a phahameng, botšepehi le ho nepahala bakeng sa mefuta e mengata ea lits'ebetso tse hlokang boiteko. Ka boitlamo ba rona ba boleng, tlhahiso e tsoetseng pele, le khotsofalo ea bareki, re molekane ea tšepahalang bakeng sa litharollo tsa li-tube tse se nang sekoli lefatšeng ka bophara.

Khetha Womic Steel bakeng sa haoLiphaephe tsa Tšepe tse se nang Mohele tsa EN 10305le ho ba le phihlelo ea lihlahisoa tse sebetsang hantle tse tšehetsoang ke boiphihlelo bo sa bapisoeng le letho.

Bakeng sa lintlha tse ling, ka kopo ikopanye le rona ka kotloloho:

Webosaete: www.womicsteel.com

Imeile: sales@womicsteel.com

Mohala/WhatsApp/WeChat: Victor: +86-15575100681 kapa Jack: +86-18390957568