1. Kakaretso ea Khamphani

Womic Steel ke moetsi ea tsebahalang lefatšeng ka bophara oa liphaephe le lipeipi tsa tšepe e sa hloekang, ea ikhethang ka thepa ea boleng bo holimo bakeng sa lits'ebetso tsa bohlokoa. Ka lilemo tse mashome tsa boiphihlelo le setsi sa tlhahiso sa sejoale-joale, re ipehile boemong ba molekane ea tšepahalang bakeng sa liindasteri tse hlokang ho nepahala, ho tšoarella le netefatso ea boleng bo felletseng. Lipeipi tsa rona tse se nang sekoli tsa SA213-TP304L li entsoe bakeng sa tikoloho e sebetsang hantle, li fana ka ho hanyetsa mafome ho sa bapisoeng le letho, matla a mechini le botšepehi ba ts'ebetso.

2. Maemo a Sebetsang

Lipeipi tsa rona tsa SA213-TP304L li entsoe ka ho latela ka botlalo ASTM A213/A213M, e hlalosang lipeipi tsa ferritic le austenitic alloy-steel boiler, superheater, le heat-exchange. Ho feta moo, lihlahisoa tsa rona li fihlela litlhoko tsa ASME Karolo ea II bakeng sa likepe tsa khatello 'me li netefalitsoe ho latela ISO 9001:2015 le PED 2014/68/EU. Litlhahlobo tsa batho ba boraro tse kang TUV, SGS, Lloyd's Register, le DNV li ka hlophisoa ho tšehetsa litokomane tse ikhethileng tsa projeke le taolo ea boleng.

3. Litekanyo le Mefuta ea Lihlahisoa

Womic Steel e fana ka lipeipi tsa SA213-TP304L ka boholo bo fapaneng ho sebetsana le lits'ebetso tse tloaelehileng le tse ikhethileng:

- Bophara ba Kantle: 6mm ho isa ho273.1mm (1/4" ho isa ho10")

- Botenya ba lebota: 0.5mm ho isa ho 12mm

- Bolelele: Ho fihlela ho limithara tse 12 kapa e etselitsoe litlhoko tse nepahetseng tsa moreki

Hape re fana ka mamello e tiileng e nang le ho kheloha ha OD ho fihlela ho ±0.05mm le ho nepahala ha botenya ba lebota ho fihlela ho ±0.03mm. Mohala oa rona oa tlhahiso o tšehetsa boholo ba metric le ba borena, ka lits'ebeletso tsa ho seha, ho kobeha le ho bevel tse ikhethileng.

4. Thepa ea Lik'hemik'hale le ea Mekaniki

SA213-TP304L ke mofuta o tlase oa tšepe e sa ruseng ea 304 e netefatsang ho tjheseletsa hantle le ho fokotsa kotsi ea ho senyeha ha li-granular kamora ho tjheseletsa. Sebopeho sa eona se hlophisitsoe hantle bakeng sa ts'epo libakeng tse nang le mocheso o phahameng le tse senyang:

Sebopeho se Tloaelehileng sa Lik'hemik'hale:

- Khabone (C): ≤ 0.035%

- Chromium (Cr): 18.0–20.0%

- Nikele (Ni): 8.0–12.0%

- Manganese (Mn): ≤ 2.00%

- Silicone (Si): ≤ 1.00%

- Fosforase (P): ≤ 0.045%

- Sebabole (S): ≤ 0.030%

Matla a Mekaniki:

- Matla a ho Thatafala: ≥ 485 MPa

- Matla a ho hlahisa: ≥ 170 MPa

- Ho lelefatsa: ≥ 35%

- Bothata: ≤ 90 HRB

Motswako ona o netefatsa tshebetso e ikgethang ditsamaisong tse jarang kgatello, dibakeng tse mabifi tsa dikhemikhale, le ditshebedisong tse phahameng tsa ho potoloha ha mocheso.

5. Ts'ebetso e Tsoetseng Pele ea Tlhahiso

Li-tube tsa SA213-TP304L tsa Womic Steel li entsoe ka ho sebelisa tatellano ea mehato ea tlhahiso e laoloang ka nepo:

1. Kgetho ya Thepa e Tala: Re reka di-billet ho bafepedi ba maemo a hodimo ba malapeng ba nang le botsitso bo tsitsitseng ba motheo. Thepa yohle e tala e netefatswa ho sebediswa theknoloji ya Positive Material Identication (PMI).

2. Ho Phunya ka Mocheso: Ho ntsha metsi ka mocheso o phahameng ho etsa hore ho be le sebopeho se se nang letho, ho netefatsa sebopeho sa lijo-thollo tse tšoanang le ho tsitsisa ho hoholo.

3. Ho Tataisa ka Mocheso: Mohato ona o ntlafatsa thepa ea mechini, o fokotsa ho teteana ha bokaholimo, 'me o tlisa lipeipi litekanyong tsa tsona tsa ho qetela.

4. Tharollo ea ho Tlama: E tsamaisoa mochesong oa 1050–1150°C e lateloang ke ho tima metsi ka potlako, mohato ona o imolla khatello ea ka hare le ho ntlafatsa ho hanyetsa mafome.

5. Ho Hloekisa le ho Fetisa: Libaka tsa tube li phekoloa ka asiti 'me li fetisoa ka lik'hemik'hale ho tsosolosa lera le sireletsang la oxide.

6. Ho otlolla le ho lekanya boholo: Liphaephe li fetisoa ka har'a mechini e nang le meqolo e mengata bakeng sa phetheho e lekanang le litekanyo 'me li lekanngoa ho latela litlhoko tsa odara.

6. Melao e Matla ea Teko

Ho netefatsa boleng bo tsitsitseng, Womic Steel e tiisa liteko tse felletseng tsa kahare le tsa motho oa boraro:

Teko ea Hydrostatic: E tiisa botšepehi ba tube ka 'ngoe tlas'a maemo a khatello e phahameng.

Teko ea Eddy Current: E lemoha mapetso a manyane le ho se tsitse ntle le ho senya tube.

Tlhahlobo ea Ultrasonic: E hlahloba ho tšoana ha sebopeho sa kahare le ho lemoha liphoso tse patiloeng.

Teko ea ho Sila ha li-granular (IGC): E netefatsa ho hanyetsa ho sila ha li-post-weld.

Teko ea ho Thatafala le ho Tiea: Thepa ea mechini e lekoa ho latela ASTM A370 ho netefatsa hore e latela melao ka botlalo.

Tlhahlobo ea Qetello ea Bokaholimo: E tiisa ho latela Ra ≤ 1.6μm (kapa ho feta moo, ho latela tlhoko).

7. Litifikeiti le Tiisetso ea Boleng

Sehlopha se seng le se seng sa dihlahiswa se tla le Setifikeiti se felletseng sa Teko ya Mill (MTC) ho ya ka EN 10204 3.1 kapa 3.2. Setsha sa Womic Steel se netefaditswe ho ya ka ISO 9001:2015, mme re bafepedi ba amohetsweng bakeng sa dikhamphani tse ngata tsa matjhaba tsa EPC. Dihlahiswa tsohle tse amanang le kgatello di netefaditswe tlasa ASME Boiler le Pressure Vessel Code le European Pressure Equipment Directive (PED).

8. Liindasteri tsa Kopo

Phaephe ea SA213-TP304L e sebelisoa haholo ho:

Tlhahiso ea Motlakase: Li-Superheater, li-reheater, le li-condenser

Limela tsa Lik'hemik'hale le tsa Petrochemical: Methapo ea ts'ebetso le lijana tsa khatello

Meriana: Mekgwa e hlwekileng ya mouoane le WFI (Metsi bakeng sa ho Enta)

Lijo le Dino: Tsamaiso ya metsi a hlwekileng

Boenjiniere ba Likepe: Li-exchange tsa mocheso le mela e pholisang metsi a leoatle

Oli le Khase: Phetiso ea khase e theohelang le mela e phatlohang

Ho hanyetsa mafome le bokhoni ba eona ba ho mamella khatello ea mocheso e potolohang ho etsa hore e be ea bohlokoa haholo maemong a feteletseng.

9. Potoloho ea Tlhahiso le Nako ea Pele ea Phano

Womic Steel e fana ka linako tsa ho fana tse etelletseng pele indastering tse tšehetsoang ke liketane tsa phepelo tse ntlafalitsoeng le tlhahiso e kholo:

- Nako e Tloaelehileng ea Tlhahiso:15–Matsatsi a 25 a mosebetsi

- Thomello e Potlakileng bakeng sa Liodara tse Potlakileng: Ho fihlela matsatsi a 10 a mosebetsi

- Bokgoni ba Tlhahiso ya Kgwedi le Kgwedi: Ditone tse fetang 1200

- Lethathamo la Lintho tse Tala: Li-billet tse fetang 500 tse seng li loketse ho huloa li teng setokong

Sena se netefatsa ho tenyetseha le ho tšepahala, esita le tlas'a kemiso e thata ea projeke.

10. Sephutheloana le ho Latela Moralo

Sephutheloana sa rona se netefatsa tšireletso e felletseng le ho latelwa ha lintho nakong ea lipalangoang le polokelo:

- Likoahelo tsa polasetiki li thibela tšilafalo

- E phuthetsoe 'me e phuthetsoe ka filimi e thibelang mafome le mabanta a lohiloeng

- Mabokose a lehong a loketseng ho sesa kapa diphalete bakeng sa ho romelwa ka dikontenara

- Sephutheloana se seng le se seng se tšoailoe ka nomoro ea mocheso, boholo, thepa, ID ea sehlopha, le khoutu ea QR

Sena se dumella bareki ho latela tube e 'ngoe le e 'ngoe ho khutlela mochesong oa eona oa tlhahiso bakeng sa ponaletso e felletseng.

11. Matla a Lipalangoang le Tsamaiso ea Lipalangoang

Womic Steel e sebetsa ho tsoa likoung tse kholo tsa Chaena, e fana ka thepa e boreleli ea lefats'e:

- Thomello ea FCL le LCL ka ntlafatso ea setshelo

- Lithapo tsa tšepe le li-wedge tsa lehong ho sireletsa thepa

- Tšebelisano-'moho le barekisi ba thepa ba ka sehloohong bakeng sa ho romelloa ha thepa ka nako e loketseng

- Tšehetso ea ho hlakola lekhetho le ho hokahanya tlhahlobo ea pele ho thomello

Bareki ba rua molemo ho lintlafatso tsa ho romella ka nako ea sebele le li-ETA tse nepahetseng.

12. Ts'ebetso le Tlhahiso ea Ka Hare

Re feta tlhahiso ea lipeipi ka ho fana ka lits'ebeletso tsa ts'ebetso tse etselitsoeng uena ka tsela e ikhethileng:

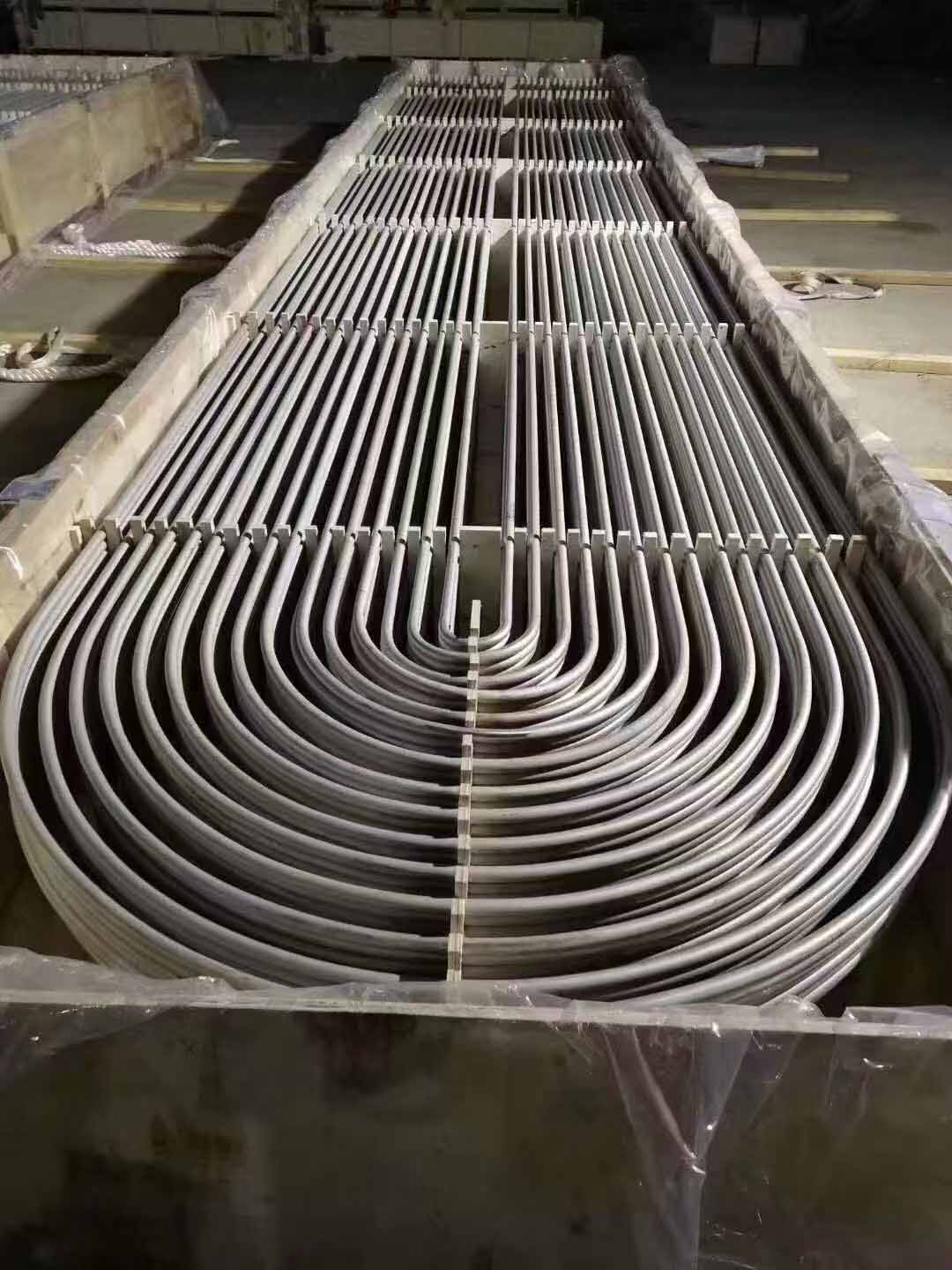

- Ho thehoa ha khoele e kobehang ka U le e nang le serpentine

- Ho benya, ho kopanya khoele le ho shebana le qetello

- Ho betloa le ho phunyeha ha lipeipi tsa sefe

- Ho bentša bokaholimo (Ra ≤ 0.4μm bakeng sa ts'ebeliso ea bohloeki)

Litšebeletso tsena tse eketsang boleng li felisa tlhoko ea barekisi ba bobeli, li boloka nako le litšenyehelo tsa bareki.

13. Ke Hobane'ng ha U Lokela ho Khetha Tšepe ea Womic?

Womic Steel e fana ka tharollo e sa hloekang e nang le mahlakore a felletseng e nang le melemo e ke keng ea bapisoa:

- Ho fumaneha ha thepa e tala ka potlako ka tšebelisano-'moho ea nako e telele ea fektheri

- Mela e iketsang bakeng sa ho taka, ho tjhesa le ho hlahloba

- Baenjiniere ba tekheniki ba nang le boiphihlelo ba lilemo tse fetang 20 tšimong

- Tšebeletso ea bareki e arabelang le tšehetso ea lipuo tse ngata

- Taolo ea boleng sebakeng seo le ho sala morao ka 100%

Ho tloha tlhahisong ea mohlala ho isa tlhahisong e kholo, re netefatsa botšepehi ba maemo a holimo, botsitso le khotsofalo ea bareki.

Khetha Womic Steel Group e le molekane oa hau ea tšepahalang bakeng saLiphaephe tsa Tšepe e sa Khaotsengle ts'ebetso e sa hlōloeng ea ho fana ka thepa. Rea u amohela!

Webosaete: www.womicsteel.com

Imeile: sales@womicsteel.com

Mohala/WhatsApp/WeChat: Victor: +86-15575100681 kapa Jack: +86-18390957568

Nako ea poso: Mmesa-21-2025