1. Selelekela sa Liphaephe tsa ho Cheka Boima bo Boima

Liphaephe tsa ho phunya ke likarolo tsa bohlokoa tse hokahanyang lisebelisoa tsa bokaholimo le lisebelisoa tsa mokoti o ka tlase.Liphaephe tsa ho Cheka Boima bo Boima (HWDP), jwalo ka diphaephe tse ikgethang tsa ho tjheka, di sebetsa e le karolo ya phetoho pakeng tsa diphaephe tse tlwaelehileng tsa ho tjheka le dikholara tsa ho tjheka. Ka moralo o ntlafaditsweng wa meaho le thepa e tswetseng pele, HWDP e bapala karolo ya bohlokwa ho jareng mojaro, ho thibolla ho thothomela, le ho tsitsisa tsela ya ho tjheka ka hara maemo a rarahaneng.

Likarolo tsa Bohlokoa tsa Moralo:

Phetoho ea Sebopeho: Marokho a liphaephe tsa ho tjheka tse "tenyetsehang" le likholara tsa ho tjheka tse "thata", tse fokotsang khatello ea maikutlo libakeng tse kopanang.

Botenya ba Lebota bo Ntlafalitsoeng: e teteaneng ka makhetlo a 2-3 ho feta liphaephe tse tloaelehileng tsa ho tjheka ha e ntse e boloka bophara bo tšoanang ba kantle (mohlala, φ50 mm, φ89 mm) bakeng sa ho tsamaisana le ts'ebetso.

Likopo tse ngata tse sebetsang: E nkela dikholara tsa ho tjheka sebaka ka hara ho tjheka ka masoba a masesaane, e fokotsa dikotsi tsa torque le tsa diphaephe tse kgomaretsweng didibeng tse shebaneng le tsela, mme e nolofalletsa taolo e nepahetseng ya boima ba motlakase (WOB).

2. Moralo oa Sebopeho: Tiisetso e 'Meli ea Matla le Khanyetso ea ho Hloeka

2.1 Sebopeho sa 'Mele oa Phaephe

Moralo o Halefileng: Ho thekesela ha ka hare, kantle, kapa ho kopantswe dipheletsong tsa diphaephe ho ntlafatsa ho hanyetsa kgatello le tshebetso ya mokhathala.

Ho soetseha ha ka hare: E boloka bophara ba kantle bakeng sa didiba tse moqotetsane.

Ho soetseha ha kantle: E eketsa bokgoni ba mojaro wa axial bakeng sa didiba tse otlolohileng.

Ho Koaheloa ho Kopantsoeng: E loketse libaka tse feteletseng joalo ka liliba tse tebileng haholo.

Khetho ea Lintho: Di-alloy tse matla haholo (mohlala, 4145H MOD) tse nang le matla a tlhahiso a tlohang ho 55,000 ho isa ho 110,000 KSI.

2.2 Theknoloji ea Kopanyo ea Lisebelisoa

Manonyeletso a Lisebelisoa a Atolositsoeng: Eketsa sebaka sa ho kopana ho aba kgatello, kgatello le meroalo e kgutlisang.

Mekhoa ea Khokahano:

Likhokahano tse nang le khoele: Likhoele tsa API kapa tse nang le mahetla a mabeli tse nang le li-sealant bakeng sa thibelo ea ho lutla.

Meaho e Welded: Manonyeletso a kopaneng a entsoeng bakeng sa lits'ebetso tse nang le khatello e phahameng.

2.3 Hardband e Hanelang ho Tshwara

Thepa: Tungsten carbide (HRC ≥60)

Mesebetsi:E fokotsa ho senyeha ha 'mele oa liphaephe ka 50% lilibeng tse otlolohileng.

E ntlafatsa khohlano bakeng sa ho tsitsisa khoele ea ho phunya le taolo ea tsela.

3. Mesebetsi ea Bohlokoa: Ho tloha ho Phokotsong ea Khatello ea Kelello ho ea ho Tsitsiso ea Wellbore

3.1 Ho thibela khatello ea maikutlo

Ho Monya ha ho Thothometsa: Likarolo tse senyehileng le thepa e tenyetsehang li fetola ho thothomela ha kholara ea ho phunya hore e be ho qhala ha matla a tenyetsehang.

Ho Fokotsa Mocheso oa Torque: Manonyeletso a lisebelisoa a atolositsoeng a aba hape khatello ea torsional, a fokotsa ho hloleha ha mokhathala liphaepheng tse tloaelehileng.

3.2 Ntlafatso ea WOB

Melemo ea Boima: Boima bo mahareng (mohlala, 38 kg/m bakeng sa φ89 mm HWDP) pakeng tsa diphaephe tsa ho tjheka le dikholara.

Taolo e Ikamahanyang le Maemo: E lokisa WOB bakeng sa dibopeho tsa shale (e thibela phaephe e kgomarelang) le dikarolo tsa majwe a thata (e ntlafatsa ho kenella).

3.3 Tsela le Botšepehi ba Sebele

Botsitso ba tataiso: Ho kenya dithapo tse thata ho fokotsa ho thekesela ha thapo ya ho tjheka, ho boloka ditsela tse rerilweng tsa diliba.

Khahlanong le ho Putlama: E fokotsa ho phahama ha khatello sebakeng se itseng ho tloha ho kobeheng, ha potoloho ea seretse e netefatsa bohloeki ba masoba.

4. Litšebeliso tse Sebetsang

4.1 Ho Cheka Liliba Tse Tebileng Haholo

Thuto ea Nyeoe: Tashen-1 Well (botebo ba 8,408 m, >200°C, khatello ea 140 MPa).

Tshebetso: Li-alloy tse hanelang mocheso o phahameng le meralo e sa tsitsang li ile tsa hlola libopeho tse khorofo le likhatello tse potolohang.

4.2 Maemo a Phephetsang a Jeoloji

Tikoloho ea Khase e Bolila: Jiaoye-1HF Well (Fuling Shale Gas Field) e sebelisitse metsoako e kopantsoeng le lipente tse koahelang mafome ho loantša H₂S.

Liliba tse shebaneng le tataiso/tse otlolohileng: HWDP ea mofuta oa Spiral e fokolitse khohlano le taolo e ntlafetseng ea tataiso.

5. Tsoelo-pele ea Theknoloji

5.1 Mekhoa e Mecha ea Tlhahiso

Kalafo ea Mocheso: Ho tima le ho futhumatsa ho ntlafatsa ho tiea ha tshusumetso.

Netefaletso ea boleng: Teko ea ultrasonic ea 100% (UT) le tlhahlobo ea likaroloana tsa makenete (MPI).

5.2 Tlhahiso e Bohlale

Kopanyo ea MES/ERP: Ho latela ka botlalo mokhoa oa ho etsa lintho ho tloha ho odara ho ea ho phano.

Dikgetho tsa ho iketsetsa: Likhokahano tse nang le mahetla a mabeli, ho atolosoa ha hardband, le lipente tsa polasetiki tse ka hare.

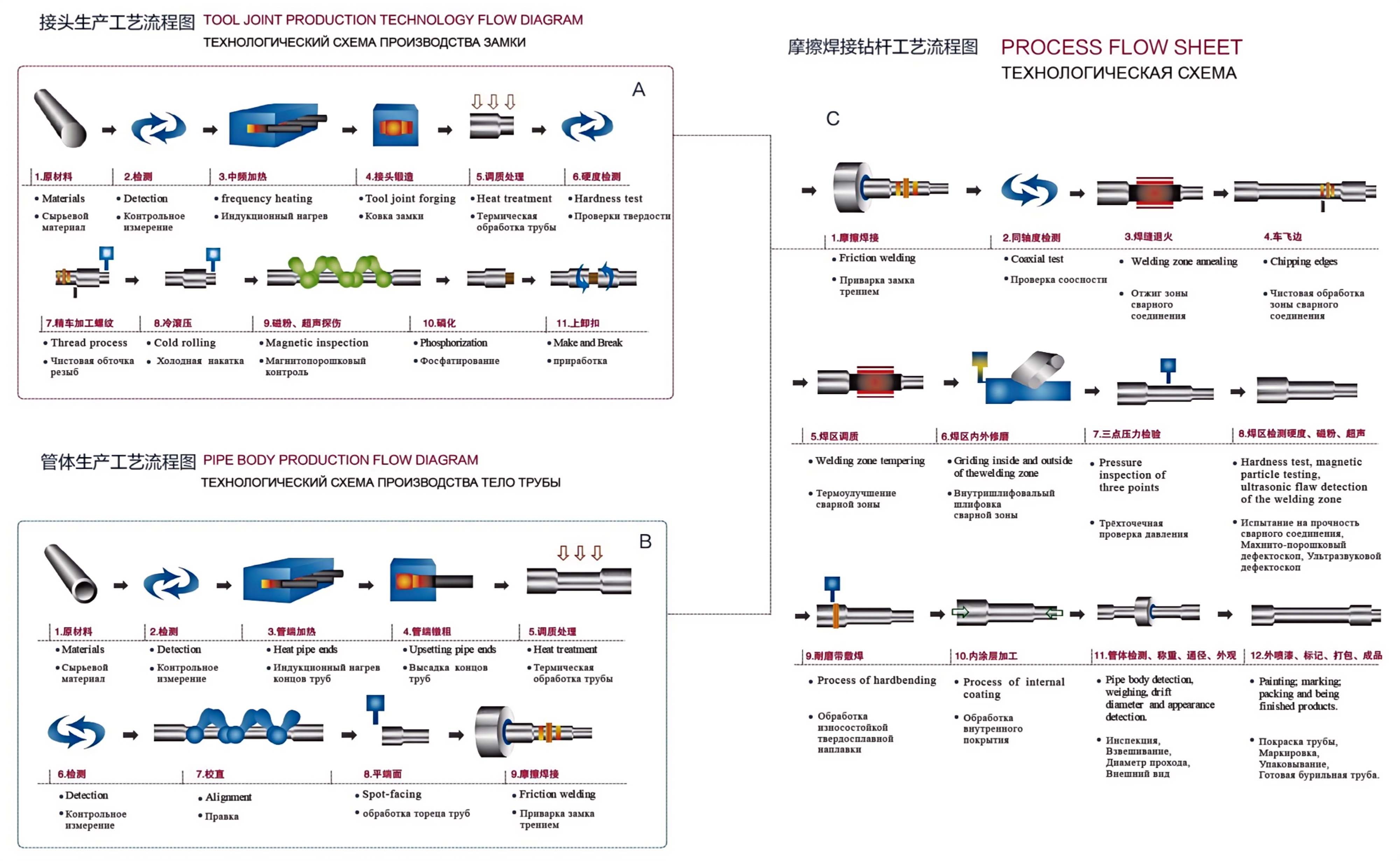

6. Ts'ebetso ea Tlhahiso

Khetho ea Lintho: Mekoallo ea tšepe ea alloy ea 4145H MOD.

Ts'ebetso ea Liphaephe: Ho tjheka → ho tjheka ka ho tjhesa → kalafo ya mocheso.

Sesebelisoa se Kopanetsoeng sa Tlhahiso: Ho qapa → ho phutholla khoele ka mokhoa o batang → ho phosphating.

Ho tjheseletsa/Kopano: Ho tjheseletsa khohlano kapa ho sebetsa ka ho kopanya.

Taolo ea Boleng: Tekanyo ea botenya ba UT, teko ea ho thatafala, netefatso ea khatello.

Phekolo ea Bokaholimo: Tšebeliso ea ho tiisa le ho roala ho thibelang mafome.

Qetello

Jwalo ka motheo wa theknoloji ya sejwalejwale ya ho tjheka, HWDP e kopanya boqapi ba meaho le saense ya thepa ho ntlafatsa polokeho le bokgoni ba ho tjheka. Ho tloha didibeng tse tebileng haholo ho ya dibopehong tse senyang, karolo ya yona e habeli e le "phetoho e tenyetsehang" le "tshehetso e tiileng" e ntse e tswela pele ho sutumelletsa meedi ya ho batla oli le kgase.

Khetha Womic Steel Group e le molekane oa hau ea tšepahalang bakeng sa liphaephe tsa ho phunya le ts'ebetso e sa hlōloeng ea ho fana ka thepa. Rea u amohela!

Webosaete: www.womicsteel.com

Imeile: sales@womicsteel.com

Mohala/WhatsApp/WeChat: Victor: +86-15575100681 kapa Jack: +86-18390957568

Nako ea poso: Mmesa-11-2025