Flange ke eng?

Ka bokhutšoanyane, flange ke lentsoe le akaretsang feela, hangata le bolela 'mele oa tšepe o tšoanang o bōpehileng joaloka disk ho bula masoba a 'maloa a tsitsitseng, o sebelisetsoang ho hokahanya lintho tse ling, mofuta ona oa ntho o sebelisoa haholo mechineng, kahoo o shebahala o makatsa hanyane, ha feela o tsejoa e le flange, lebitso la oona le tsoa ho flange ea Senyesemane. e le hore phala le khokahano ea phaephe ea likarolo, tse hokahaneng le pheletso ea phaephe, flange e na le lesoba, li-screw ho etsa li-flange tse peli. Li hokahane ka thata, pakeng tsa flange ka tiiso ea gasket.

Flange ke likarolo tse bōpehileng joaloka disk, tse tloaelehileng haholo boenjiniere ba liphaephe, flange li sebelisoa ka bobeli.

Mabapi le mefuta ea likhokahano tsa flange, ho na le likarolo tse tharo:

- Liphaephe tse benyang

- Gasket

- Khokahano ea bolt

Maemong a mangata, ho fumanoa gasket le thepa e itseng ea bolt e entsoeng ka thepa e tšoanang le karolo ea phaephe ea flange. Li-flange tse tloaelehileng haholo ke li-flange tsa tšepe e sa hloekang. Li-flange, ka lehlakoreng le leng, li fumaneha ka mefuta e fapaneng ea thepa e le hore li lumellane le litlhoko tsa sebaka seo. Tse ling tsa thepa e tloaelehileng ea flange ke monel, inconel, le chrome molybdenum, ho latela litlhoko tsa sebaka seo. Khetho e ntle ea thepa e lokela ho itšetleha ka mofuta oa sistimi eo u batlang ho sebelisa flange ka litlhoko tse itseng ho eona.

Mefuta e 7 e Tloaelehileng ea Li-Flanges

Ho na le mefuta e fapaneng ea li-flange tse ka khethoang ho latela litlhoko tsa sebaka seo. Ho lumellana le moralo oa flange e loketseng, ts'ebetso e tšepahalang hammoho le bophelo bo bolelele ba ts'ebeletso li tlameha ho netefatsoa 'me theko e loketseng ka ho fetisisa e lokela ho nahanoa.

1. flange e nang le khoele:

Li-flange tse nang le khoele, tse nang le khoele ka har'a mokoti oa flange, li kentsoe likhoele tsa kantle holim'a sehokelo. Khokahano ea khoele mona e reretsoe ho qoba ho tjheseletsa maemong 'ohle. Haholo-holo e hokahantsoe ka ho bapisa likhoele le phaephe e tla kenngoa.

2. Li-flange tsa ho weld tsa sokete

Mofuta ona oa flange hangata o sebelisoa bakeng sa liphaephe tse nyane moo bophara ba sebaka sa mocheso o tlase le khatello e tlase bo khetholloang ka khokahano eo phaephe e behiloeng ka hare ho flange ho netefatsa khokahano ka weld e le 'ngoe kapa e mengata ea fillet. Sena se qoba lithibelo tse amanang le lipheletso tse nang le khoele ha li bapisoa le mefuta e meng ea flange e welletsoeng, kahoo ho etsa hore ho kenngoa ho be bonolo.

3. Li-flange tsa maoto

Flange e kobehileng ke mofuta oa flange e hlokang hore ntlha ea stub e kobehetsoe ka har'a sehokelo e le hore e sebelisoe le flange e tšehetsang ho etsa khokahano e kobehileng. Moralo ona o entse hore mokhoa ona o ratoe litsamaisong tse fapaneng moo sebaka sa 'mele se fokolang, kapa moo ho hlokahalang ho qhaqhoa khafetsa, kapa moo ho hlokahalang tlhokomelo e phahameng.

4. Li-flange tse thellang

Li-flange tse thellang li atile haholo 'me li fumaneha ka boholo bo fapaneng ho latela litsamaiso tse nang le sekhahla se phahameng sa phallo le li-output. Ho bapisa flange le bophara ba kantle ba phaephe feela ho etsa hore khokahano e be bonolo haholo ho e kenya. Ho kenya li-flange tsena ho batla ho le thata kaha ho hloka ho tjheseletsa li-fillet mahlakoreng ka bobeli ho tiisa flange ho phaephe.

5. Li-flange tse foufetseng

Mefuta ena ea li-flange e loketse hantle bakeng sa ho felisoa ha litsamaiso tsa liphaephe. Poleiti e foufetseng e bōpehile joaloka disk e se nang letho e ka tlangoang ka boltere. Hang ha tsena li kentsoe hantle 'me li kopantsoe le gasket e nepahetseng, e lumella ho koaloa hantle 'me ho bonolo ho e tlosa ha ho hlokahala.

6. Li-Flanges tsa Molala tse Welded

Li-flange tsa molala tse entsoeng ka weld li tšoana haholo le li-flange tsa lap, empa li hloka ho tjheseletsa li-butt bakeng sa ho kenngoa. 'Me botšepehi ba ts'ebetso ea sistimi ena le bokhoni ba eona ba ho kobeha ka makhetlo a mangata le ho sebelisoa lits'ebetsong tsa khatello e phahameng le mocheso o phahameng li etsa hore e be khetho ea mantlha bakeng sa liphaephe tsa ts'ebetso.

7. Li-flange tse ikhethang

Mofuta ona oa flange ke oona o tsebahalang haholo. Leha ho le joalo, ho na le mefuta e mengata e mengata ea flange e khethehileng e fumanehang ho latela mefuta e fapaneng ea ts'ebeliso le tikoloho. Ho na le likhetho tse ling tse fapaneng tse kang li-flange tsa nipo, li-flange tsa weldo, li-flange tsa katoloso, li-orifice, melala e metelele ea weld le li-flange tsa reducer.

Mefuta e 5 e Ikhethang ea Li-Flanges

1. WeldoFlera

Lesela la weldo le tšoana haholo le la Nipo kaha ke motsoako oa li-flange tsa ho tjheseletsa mokokotlo le likhokahano tsa ho kopanya makala. Li-flange tsa weldo li entsoe ka tšepe e le 'ngoe e tiileng e entsoeng ka tšepe, ho fapana le hore likarolo tse arohaneng li kopanngoa hammoho.

2. Sekoahelo sa Nipo

Nipoflange ke phaephe ya lekala e sekametseng ka sekhutlo sa di-degree tse 90, ke sehlahisoa se entsweng ka ho kopanya di-flange tsa ho tjheseletsa mokokotlo le Nipolet e entsweng. Le hoja flange ya Nipo e fumanwa e le karolo e le nngwe e tiileng ya tshepe e entsweng, ha ho utlwisisehe hore ke dihlahiswa tse pedi tse fapaneng tse kopantsweng mmoho. Ho kenngwa ha Nipoflange ho bopilwe ka ho tjheseletsa karolong ya Nipolet ya disebediswa e le ho tsamaisa phaephe le ho tlama karolo ya flange ho flange ya phaephe ya stub ke sehlopha sa diphaephe.

Ho bohlokoa ho tseba hore li-flange tsa Nipo li fumaneha ka mefuta e fapaneng ea thepa e kang khabone, litšepe tsa khabone tse mocheso o phahameng le o tlase, limaraka tsa tšepe e sa ruseng, le li-alloy tsa nickel. Li-flange tsa Nipo li etsoa haholo-holo ka tlhahiso e matlafalitsoeng, e thusang ho li fa matla a eketsehileng a mechini ha li bapisoa le flange e tloaelehileng ea Nipo.

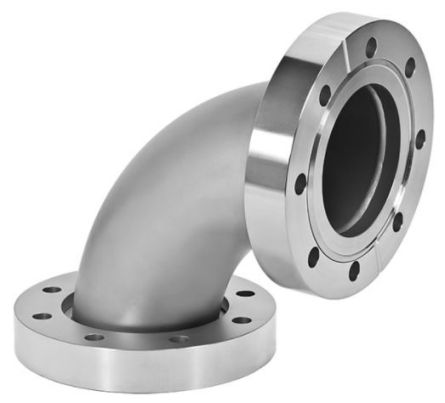

3. Elboflange le Latroflange

Elboflange e tsejoa e le motsoako oa flange le Elbolet ha Latroflange e tsejoa e le motsoako oa flange le Latrolet. Li-flange tsa litsoeng li sebelisoa ho liphaephe tsa makala ka sekhutlo sa likhato tse 45.

4. Li-flange tsa lesale tse potolohang

Tšebeliso ea li-flange tsa lesale le potolohang ke ho nolofatsa ho hokahanya masoba a li-bolt pakeng tsa li-flange tse peli tse kopantsoeng, e leng se thusang haholo maemong a mangata, joalo ka ho kenya liphaephe tse bophara bo boholo, liphaephe tsa metsing kapa tsa leoatleng le libaka tse tšoanang. Mefuta ena ea li-flange e loketse maro a hlokang oli, khase, li-hydrocarbon, metsi, lik'hemik'hale le lits'ebetso tse ling tsa petrochemical le tsamaiso ea metsi.

Tabeng ea liphaephe tse bophara bo boholo, phaephe e kentsoe flange e tloaelehileng ea weld ea butt pheletsong e 'ngoe le flange e potolohang ka lehlakoreng le leng. Sena se sebetsa ka ho potoloha flange e potolohang phaepheng e le hore opereishene a fihlelle ho lekana hantle ha masoba a liboutu ka tsela e bonolo haholo le e potlakileng.

Tse ling tsa maemo a mantlha bakeng sa li-flange tsa lesale le potolohang ke ASME kapa ANSI, DIN, BS, EN, ISO, le tse ling. E 'ngoe ea maemo a tsebahalang haholo bakeng sa ts'ebeliso ea petrochemical ke ANSI kapa ASME B16.5 kapa ASME B16.47. Li-flange tse potolohang ke li-flange tse ka sebelisoang ka libopeho tsohle tse tloaelehileng tsa flange. Mohlala, li-weld melala, li-slip ons, li-lap joints, li-socket welds, jj., maemong ohle a thepa, ka boholo bo fapaneng ho tloha ho 3/8" ho isa ho 60", le khatello ho tloha ho 150 ho isa ho 2500. Li-flange tsena li ka etsoa habonolo ka carbon, alloy le litšepe tse sa hloekang.

5. Li-flange tsa katoloso

Li-flange tsa katoloso, li sebelisoa ho eketsa boholo ba mokoti oa phaephe ho tloha ntlheng efe kapa efe ho ea ho e 'ngoe e le ho hokahanya phaephe le lisebelisoa tse ling tsa mechini tse kang lipompo, li-compressor, le li-valve tse fumanoang li na le boholo bo fapaneng ba ho kena.

Hangata di-flange tsa katoloso ke di-flange tse tjheseditsweng ka marago tse nang le lesoba le leholo haholo pheletsong e sa tjhesetsweng. E ka sebediswa ho eketsa boholo bo le bong kapa bo babedi feela kapa ho fihlela ho di-inchi tse 4 ho phaephe e mathang. Mefuta ena ya di-flange e kgethwa ho feta motswako wa di-reducer tsa butt-weld le di-flange tse tlwaelehileng hobane di theko e tlase ebile di bobebe. E nngwe ya thepa e tlwaelehileng e sebediswang bakeng sa di-flange tsa katoloso ke A105 le tshepe e sa ruseng ASTM A182.

Li-flange tsa katoloso li fumaneha ka litekanyetso tsa khatello le boholo ho latela litlhaloso tsa ANSI kapa ASME B16.5, tse fumanehang haholo-holo ka khoele kapa ka sephara (RF kapa FF). Li-flange tsa ho fokotsa, tse tsejoang hape e le li-flange tsa ho fokotsa, li sebeletsa mosebetsi o fapaneng hantle ha li bapisoa le li-flange tsa katoloso, ho bolelang hore li sebelisetsoa ho fokotsa boholo ba sekoti sa phaephe. Bophara ba sekoti sa phaephe bo ka fokotsoa habonolo, empa eseng ka boholo bo fetang 1 kapa 2. Haeba ho etsoa boiteko ba ho fokotsa ka nģ'ane ho sena, tharollo e thehiloeng motsoakong oa li-reducer tse phuthetsoeng ka mokokotlo le li-flange tse tloaelehileng e lokela ho sebelisoa.

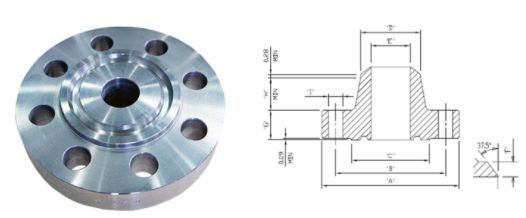

Boholo ba Flange le Lintho Tse Tloaelehileng Tse Loketseng

Ntle le moralo o sebetsang oa flange, boholo ba eona ke eona ntho e ka susumetsang khetho ea flange ha ho raloa, ho hlokomeloa le ho ntlafatsoa ha sistimi ea liphaephe. Ho e-na le hoo, ho lokela ho nahanoa ka sebopeho sa flange le phala le li-gasket tse sebelisoang ho netefatsa boholo bo nepahetseng. Ho phaella ho sena, lintlha tse ling tse tloaelehileng ke tse latelang:

- Bophara ba kantle: Bophara ba kantle ke sebaka se pakeng tsa mathoko a mabedi a fapaneng a sefahleho sa flange.

- Botenya: Botenya bo lekanngoa ho tloha ka ntle ho moedi.

- Bophara ba Selikalikoe sa Bolt: Ena ke sebaka se pakeng tsa masoba a bolt a lekantsoeng ho tloha bohareng ho ea bohareng.

- Boholo ba Phaephe: Boholo ba phaephe ke boholo bo tsamaellanang le phaephe.

- Bore e sa Reroang: Bore e sa Reroang ke boholo ba bophara ba kahare ba sehokelo sa flange.

Tlhophiso ea Flange le Boemo ba Tšebeletso

Li-flange li arotsoe haholo-holo ka bokhoni ba tsona ba ho mamella mocheso le likhatello tse fapaneng. Li khetholloa ka tšebeliso ea litlhaku kapa li-suffix "#", "lb" kapa "class". Tsena ke li-suffix tse ka fetoloang 'me li boetse li fapana ho ea ka sebaka kapa mofani. Lihlopha tse tsebahalang tse tloaelehileng li thathamisitsoe ka tlase:

- 150#

- 300#

- 600#

- 900#

- 1500#

- 2500#

Matla a tšoanang a khatello le mamello ea mocheso a fapana ho latela thepa e sebelisitsoeng, moralo oa flange le boholo ba flange. Leha ho le joalo, ntho e le 'ngoe feela e sa fetoheng ke tekanyo ea khatello, e fokotsehang ha mocheso o ntse o eketseha.

Mofuta oa Sefahleho sa Flange

Mofuta oa sefahleho le oona ke tšobotsi ea bohlokoa haholo e nang le tšusumetso e kholo ts'ebetsong ea ho qetela le bophelo ba tšebeletso ea flange. Ka hona, tse ling tsa mefuta ea bohlokoa ka ho fetisisa ea lifahleho tsa flange li hlahlojoa ka tlase:

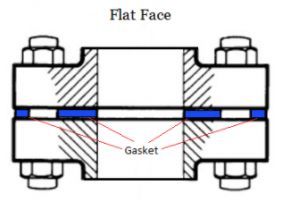

1. Flange e bataletseng (FF)

Bokaholimo ba gasket ea flange e bataletseng bo sebakeng se le seng le bokaholimo ba foreimi e nang le bolti. Thepa e sebelisang li-flange tse bataletseng hangata ke tse entsoeng ka hlobo ho tsamaisana le sekoahelo sa flange kapa flange. Li-flange tse bataletseng ha lia lokela ho beoa holim'a li-flange tse ka lehlakoreng le sothehileng. ASME B31.1 e re ha ho kopanngoa li-flange tsa tšepe e bataletseng le li-flange tsa tšepe ea carbon, sefahleho se phahamisitsoeng holim'a li-flange tsa tšepe ea carbon se tlameha ho tlosoa 'me ho hlokahala gasket e felletseng ea sefahleho. Sena ke ho thibela li-flange tse nyane, tse brittle tsa tšepe e qhibilihisitsoeng hore li se ke tsa phatloha ka har'a sekheo se entsoeng ke nko e phahamisitsoeng ea flange ea tšepe ea carbon.

Mofuta ona wa sefahleho sa flange o sebediswa tlhahisong ya disebediswa le di-valve bakeng sa ditshebediso tsohle moo tshepe e entsweng teng. Tshepe e qhibidihileng e robeha habonolo mme hangata e sebediswa feela bakeng sa ditshebediso tse tlase tsa mocheso le kgatello e tlase. Sefahleho se bataletseng se dumella di-flange ka bobedi ho kopana ka botlalo hodima bokahodimo bohle. Di-Flat Flange (FF) di na le bokahodimo ba ho kopana bo bolelele bo lekanang le dikgwele tsa bolt tsa flange. Di-washer tse felletseng tsa sefahleho di sebediswa pakeng tsa di-flange tse pedi tse bataletseng mme hangata di bonolo. Ho ya ka ASME B31.3, di-flange tse bataletseng ha di a lokela ho kopanngwa le di-flange tse phahameng ka lebaka la kgonahalo ya ho dutla ho tswa ho lenonyello le qhibidihileng le hlahang.

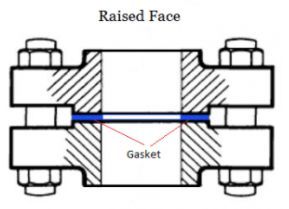

2. Flange e Phahameng ea Sefahleho (RF)

Flange e phahamisitsoeng sefahlehong ke mofuta o tloaelehileng haholo o sebelisoang lits'ebetsong tsa moetsi 'me e bonoa habonolo. E bitsoa convex hobane sefahleho sa gasket se ka holim'a sefahleho sa lesale la bolt. Mofuta o mong le o mong oa sefahleho o hloka tšebeliso ea mefuta e 'maloa ea gasket, ho kenyeletsoa mefuta e fapaneng ea li-tab tsa lesale le bataletseng le metsoako ea tšepe e kang libopeho tsa leqeba le nang le spiral le tse nang le sheath e habeli.

Li-flange tsa RF li etselitsoe ho tsepamisa khatello e eketsehileng sebakeng se senyenyane sa gasket, ka hona ho ntlafatsa taolo ea khatello ea lenonyello. bophara le bophahamo ka boemo ba khatello le bophara li hlalositsoe ho ASME B16.5. Boemo ba khatello ea Flange bo totobatsa bophahamo ba sefahleho se phahamisoang. Li-flange tsa RF li reretsoe ho tsepamisa khatello e eketsehileng sebakeng se senyenyane sa gasket, ka hona ho eketsa bokhoni ba taolo ea khatello ea lenonyello. Bophara le bophahamo ka sehlopha sa khatello le bophara li hlalositsoe ho ASME B16.5. Litekanyetso tsa flange ea khatello.

3. Lesela la lesale (RTJ)

Ha ho hlokahala tiiso ya tshepe ho ya ho tshepe pakeng tsa di-flange tse kopaneng (e leng boemo ba tshebediso ya kgatello e phahameng le mocheso o phahameng, ke hore, ka hodimo ho 700/800 C°), Ring Joint Flange (RTJ) e a sebediswa.

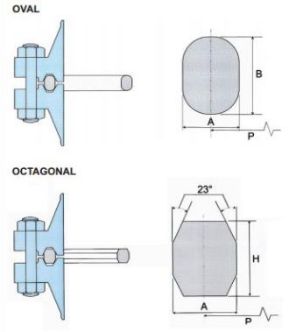

Flange ea lenonyello la lesale e na le mokoti o chitja o amohelang gasket ea lenonyello la lesale (e oval kapa e khutlonnetsepa).

Ha di-flange tse pedi tsa lesale di kopantswe mmoho ebe di tiiswa, matla a bolt a sebediswang a fetola gasket ka hara lesoba la flange, e leng se etsang hore ho be le tiiso e tiileng haholo ya tshepe ho ya ho tshepe. E le ho phethahatsa sena, thepa ya gasket ya lesale e tlameha ho ba bonolo (e ductile haholoanyane) ho feta thepa ya di-flange.

Li-flange tsa RTJ li ka koaloa ka li-gasket tsa RTJ tsa mefuta e fapaneng (R, RX, BX) le liprofaele (mohlala, octagonal/elliptical bakeng sa mofuta oa R).

Gasket e tloaelehileng haholo ea RTJ ke mofuta oa R o nang le karolo e tšekaletseng ea octagonal, kaha e netefatsa tiiso e matla haholo (karolo e tšekaletseng ea oval ke mofuta oa khale). Leha ho le joalo, moralo oa "flat groove" o amohela mefuta ka bobeli ea gasket ea RTJ e nang le karolo e tšekaletseng ea octagonal kapa oval.

4. Li-flange tsa leleme le groove (T & G)

Li-flange tse peli tsa leleme le groove (lifahleho tsa T & G) li lekana hantle: flange e 'ngoe e na le lesale le phahamisitsoeng 'me e 'ngoe e na le li-groove moo li kenang habonolo (leleme le kena ka har'a groove 'me le tiisa lenonyello).

Li-flange tsa leleme le tsa groove li fumaneha ka boholo bo boholo le bo bonyenyane.

5. Li-Flanges tsa Banna le Basali (M & F)

Ho tšoana le li-flange tsa leleme le li-groove, li-flange tsa banna le tsa basali (mefuta ea sefahleho sa M & F) lia tšoana.

Flange e 'ngoe e na le sebaka se atolohang ka nģ'ane ho sebaka sa eona sa bokaholimo, flange ea banna, 'me flange e 'ngoe e na le likoti tse tšoanang tse kentsoeng holim'a bokaholimo bo shebileng, flange ea basali.

Sefahleho sa Flange se Qetella

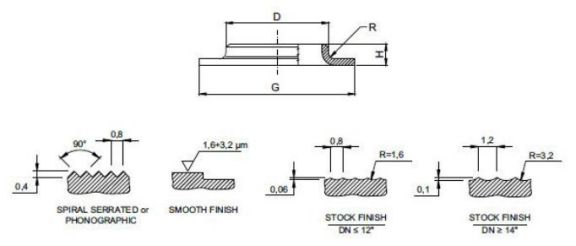

E le ho netefatsa hore flange e lekana hantle le gasket le flange e kopanang, sebaka sa bokaholimo ba flange se hloka tekanyo e itseng ea ho ba thata (liqetello tsa flange tsa RF le FF feela). Mofuta oa ho ba thata ha bokaholimo ba sefahleho sa flange o hlalosa mofuta oa "qetello ea flange".

Mefuta e tloaelehileng ke lifahleho tse teteaneng, tse nang le serrated tse tebileng, tse nang le serrated tse potolohang le tse boreleli tsa flange.

Ho na le diqeto tse nne tsa motheo tsa bokaholimo bakeng sa di-flange tsa tshepe, leha ho le jwalo, sepheo se tshwanang sa mofuta ofe kapa ofe wa qetello ya bokaholimo ba flange ke ho hlahisa ho hlaka ho lakatsehang bokaholimong ba flange ho netefatsa hore ho lekana hantle pakeng tsa flange, gasket le flange e kopanyang ho fana ka tiiso ya boleng.

Nako ea poso: Mphalane-08-2023