1.Kakaretso ea Sehlahisoa

Womic Steel e ikhethile ka tlhahiso ea lipeipi tsa koporo tsa boleng bo holimo tse lumellanang le maemo a EN 1057. Lipeipi tsena li entsoe ka thepa ea Cu-DHP (CW024A), e netefatsang bohloeki bo ikhethang le ts'ebetso bakeng sa lits'ebetso tsa liphaephe, kabo ea khase, ho futhumatsa le ho pholisa. Ka bonyane koporo le silevera tse nang le 99.9% le phosphorus e laoloang pakeng tsa 0.015% le 0.040%, lipeipi tsa rona tsa koporo li bontša ho hanyetsa mafome hantle, ho tšoarella le bonolo ba ho li kenya.

Liphaephe tsa koporo tsa EN 1057 li etselitsoe ho sebelisoa libakeng tsa malapeng le tsa indasteri, li fana ka ts'ebetso e tšepahalang lits'ebetsong tsa metsi a nooang, liphaepheng tsa ho futhumatsa bohareng, sehatsetsing le tsa khase ea bongaka. Li entsoe ka maemo a thata a boleng, liphaephe tsena li fana ka thepa e phahameng ea mechini le ts'epo ea ts'ebeletso ea nako e telele.

2.EN 1057 Copper Tubes Production Range

●Bophara ba Kantle (OD):6 mm ho isa ho 267 mm

●Botenya ba lebota (boima):0.3mm ho isa ho20mm

●Bolelele:Bolelele bo tloaelehileng ba 3m, 5m, kapa 6m; bolelele bo ikhethileng bo fumaneha ha bo kopuoa

●Liphaephe tse kobehileng:E fumaneha ka likhoele tsa 25m kapa 50m bakeng sa ho kenngoa ho tenyetsehang

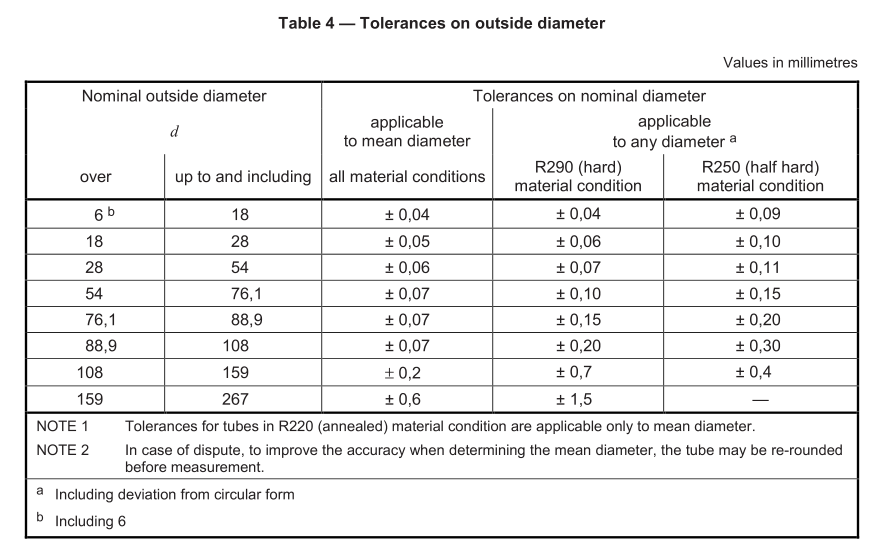

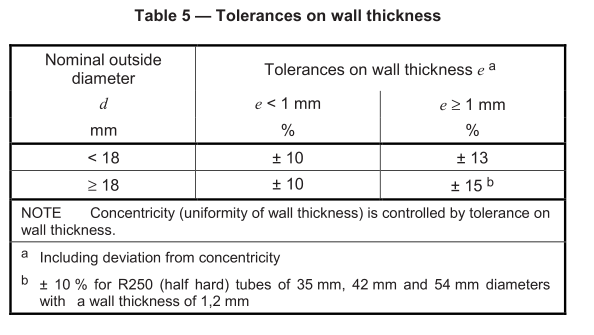

3.EN 1057 Copper Tubes Tolerances

Tšepe ea Womic e netefatsa ho nepahala ho nepahetseng ha litekanyo ka mamello e latelang:

4.EN 1057 Sebopeho sa Lik'hemik'hale tsa Liphaephe tsa Koporo

Lipeipi tsa rona tsa koporo li entsoe ka thepa ea Cu-DHP (CW024A) ka motsoako o latelang:

Sebopeho se lokela ho latela ditlhoko tse latelang:

Cu + Ag: bonyane 99,90 %;

0,015 %≤P≤0,040 %.

Sehlopha sena sa koporo se kgethwa hore e be Cu-DHP kapa CW024A.

Sebopeho sena se netefatsa ho hanyetsa ho ts'oha ho hoholo, ho tsamaisa mocheso o phahameng le motlakase, le ho sebetsa hantle haholo.

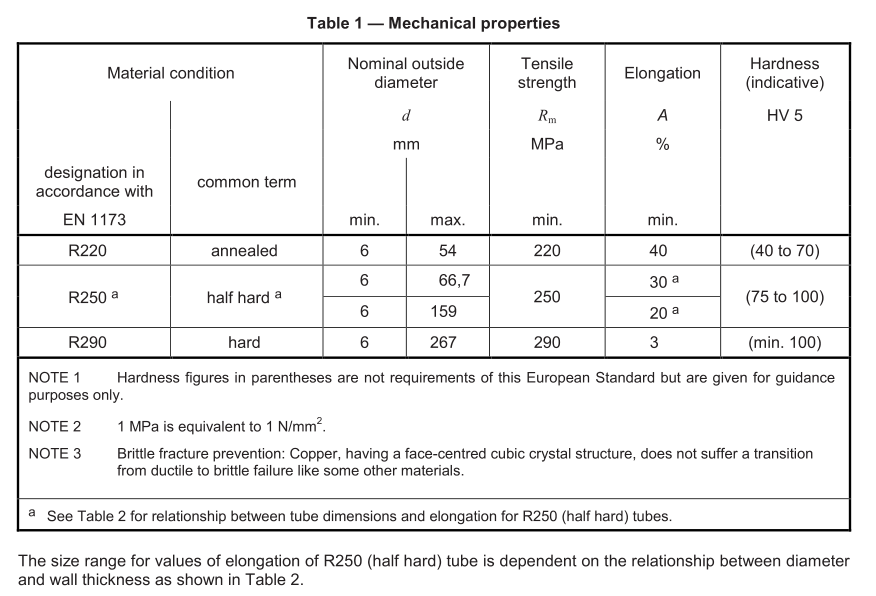

5.EN 1057 Litšebeletso tsa Mechini tsa Lipeipi tsa Koporo

Thepa ea mechini ea lipeipi tsa rona tsa koporo tsa EN 1057 e itšetlehile ka boemo ba ho tlisoa:

6.Maemo a ho Romela Liphaephe tsa Koporo tsa EN 1057

Womic Steel e fana ka lipeipi tsa koporo tsa EN 1057 maemong a latelang a mocheso:

●R220 (E annealed): E tenyetseha haholo, e loketse ho kobeha le ho bopa

●R250 (Halofo-Thata): Matla a mahareng, ho leka-lekana ho hotle ha ho tenyetseha le ho tšoarella

●R290 (E thata): Matla a phahameng, a loketse lits'ebetso tse otlolohileng tse nang le ho kobeha ho fokolang

7.EN 1057 Ts'ebetso ea Tlhahiso ea Li-Tube tsa Koporo

Ts'ebetso ea rona ea tlhahiso e tsoetseng pele e netefatsa maemo a boleng bo holimo ka ho fetisisa:

1. Ho Lokisa le ho Lokisa Billet: Koporo e hloekileng haholo e qhibilihisoa ebe e lahleloa ka har'a billets.

2. Ho Ntša le ho Phunya: Li-billet li ntšoa ka mokhoa oa tube 'me li phunngoa ho latela litekanyo tse hlokahalang.

3. Setšoantšo se batang: Liphaephe li huloa ka har'a li-dies ho fihlela litekanyo tse nepahetseng.

4. Ho annealing: Kalafo ea mocheso e sebelisoa ho fihlela litšobotsi tse hlokahalang tsa mechini.

5. Ho otlolla le ho Seha: Liphaephe lia otlolloa le ho khaoloa ka bolelele bo hlokahalang.

6.Tlhahlobo le Teko: Liteko tse matla tsa boleng li netefatsa hore li latela maemo a EN 1057.

8.Teko le Tlhahlobo

Womic Steel e netefatsa taolo e felletseng ea boleng ka liteko tse felletseng, ho kenyeletsoa:

●Tlhahlobo ea Lik'hemik'hale/Li-Spectrographic: Netefatso ea motsoako oa thepa ho sebelisoa mekhoa ea lik'hemik'hale kapa ea li-spectroscopic.

●Teko ea ho Tenyetseha: Tlhahlobo ea matla a ho tenyetseha le thepa ea ho lelefatsa (EN 10002-1).

●Teko ea ho tiea: Tekanyo ea ho tiea ha thepa ka mokhoa oa Vickers (EN ISO 6507-1).

●Teko ea Khabone: Ho fumana palo ea peresente ea khabone ho sebelisoa mokhoa oa litšupiso oa EN 723.

●Teko ea Filimi ea Khabone: Ho lemoha le ho hlahloba boteng ba filimi ea khabone (Sehlomathiso B).

●Teko ea ho kobeha: Tlhahlobo ea ho kobeha tlas'a

●Teko ea ho Atolosa Moqomo: Katoloso ea pheletso ea tube ka 30% ka45°mandrel e kobehileng ho netefatsa ho ductility (EN ISO 8493).

●Teko ea ho Fokotsa: Netefatso ea ho thehoa ha flange (keketseho ea bonyane 30% ea bophara ba tube) ho sebelisoa sesebelisoa se nang le radius ea sekhutlo sa 1 mm (EN ISO 8494).

●Liteko tsa Tokoloho ho Liphoso:

●Teko ea Hona Joale ea Eddy (ECT): Ho lemoha liphoso tsa bokaholimo/ka tlas'a lefatše (EN 1971 & Annex C.1).

●Teko ea Hydrostatic: Netefatso ea ho hanyetsa khatello ka khatello ea metsi (Sehlomathiso C.2).

●Teko ea Pneumatic: Ho lemoha ho dutla ha metsi ho sebelisoa khatello ea moea/khase (Sehlomathiso C.3).

●Hlokomela: Taelo ea tlhahlobo ea mofuta oa pele ke ECT; mekhoa e meng ke khetho ea moetsi.

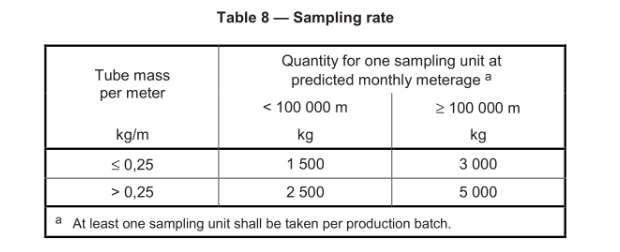

9. Ho etsa disampole:

Bakeng sa netefatso ea boleng nakong ea tlhahiso, palo ea li-sampuli tse lokelang ho nkuoa ka mokhoa o sa reroang e tla baho ya ka Tafole ya 8.

Sekgahla sena sa ho nka disampole se tla sebetsa ha ho lekoa ditaolo tsa boholo; ditaolo tsa thepa e meng e tlamang di tla etswa yuniting e nngwe le e nngwe ya bobedi ya ho nka disampole.

Liphetho li ka sebelisoa ho tsoa litlhahlobong tse entsoeng mohatong oa pele oa tlhahiso ea sehlahisoa, mohlala, mohatong oa ho lahla kapa oa ho kenya li-billets, haeba boitsebiso ba sehlahisoa bo bolokiloe 'me haeba sistimi ea taolo ea boleng ea moetsi e latela litlhoko tse amehang tsa EN lSO 9001.

10.Sephutheloana

Ho netefatsa hore lipeipi tsa rona tsa koporo lia tšoaroa le ho tsamaisoa ka mokhoa o sireletsehileng, liphutheloana tsa rona tsa koporo li phuthetsoe ka tsela e latelang:

●Seaparo se Thibelang ho Kena ha Oxidation: Lera le sireletsang le sebediswa hodima diphaephe tsa koporo ho thibela ho kenwa ha oxidation le ho fetoha ha mmala nakong ya polokelo le ho tsamaiswa.

●Li-cap tsa Qetello: Li-cap tsa polasetiki kapa tsa tšepe tse sa senyeheng li kenngoa lipheletsong tsa lipeipi ho thibela tšilafalo le tšenyo ea mechine.

●Tlamo: Liphaephe li hlophisitsoe ka litlhaloso 'me li tlameletsoe ka thata ka marapo a polasetiki a matla ho fokotsa motsamao nakong ea ho tsamaea.

●Sekepe sa Lehong: Liphaephe tse kopantseng di kenngwa ka hara dikreite tsa lehong tse hanelang mongobo. Dikreite di manehilwe ka foam e sa keneleng metsi kapa thepa ya desiccant ho thibela tshenyo ya mongobo le ho latela maemo a ISPM 15 a matjhaba a bohloeki ba dimela.

●Ho Tiisoa ho Matlafalitsoeng: Likereiti li koetsoe ka mabanta a tšepe kapa lihokelo tse boima. Ho phuthela ka mokhoa o ikhethileng hoa fumaneha bakeng sa ho thibela boemo ba leholimo bo eketsehileng.

●Ho ngolwa: Kreiti ka 'ngoe e ngolwa ka bophara ba kantle ba tube (OD), botenya ba lebota (WT), bolelele, mocheso (mohlala, bonolo, halofo-thata), nomoro ea sehlopha sa tlhahiso, le letsatsi ho netefatsa hore e ka sala morao ka botlalo.

11.Lipalangoang le Thepa

Tšepe ea Womic e netefatsa hore lipeipi tsa koporo tsa EN 1057 li tla ka nako e nepahetseng le ka mokhoa o sireletsehileng:

●Mesebetsi ea Leoatleng: Thomello ea lefats'e ka har'a lijana tse nang le tšireletso e nepahetseng

●Lipalangoang tsa Terene kapa tsa Tsela: Lipalangoang tse tšepahalang tsa malapeng le tsa libaka

●Lipalangoang tse Laoloang ke Boemo ba Leholimo: Li fumaneha bakeng sa lits'ebetso tse bonolo

●Litokomane tse Felletseng: Litokomane tsa ho romella le inshorense lia fanoa

●Koporo e Hloekileng ka ho Fetisisa: E tšoarella ka mokhoa o ikhethang le ho hanyetsa ts'enyeho

● Tlhahiso e Nepahetseng: Tolerances e tiileng ea litekanyo bakeng sa ts'ebetso e tšepahalang

●Litharollo tse Ikhethileng: Bolelele, mocheso le masela a koahetsoeng a etselitsoeng uena aa fumaneha

●Teko e Felletseng: Ho netefatsa hore ho latela maemo a machaba

●Kabo ea Lefatše: Thomello e tšepahalang le e nakong lefatšeng ka bophara

12.Melemo ea ho Khetha Tšepe ea Basali

- ●Koporo e Hloekileng ka ho Fetisisa: E tšoarella ka mokhoa o ikhethang le ho hanyetsa ts'enyeho

- ● Tlhahiso e Nepahetseng: Tolerances e tiileng ea litekanyo bakeng sa ts'ebetso e tšepahalang

- ●Litharollo tse Ikhethileng: Bolelele, mocheso le masela a koahetsoeng a etselitsoeng uena aa fumaneha

- ●Teko e Felletseng: Ho netefatsa hore ho latela maemo a machaba

- ●Kabo ea Lefatše: Thomello e tšepahalang le e nakong lefatšeng ka bophara

13.Likopo

Liphaephe tsa koporo tsa EN 1057 li sebelisoa haholo ho:

- Mekhoa ea Liphaephe: Kabo e sireletsehileng le e tšepahalang ea metsi a nooang

- Kabo ea Khase: E loketse tšebeliso ea khase ea tlhaho le LPG

- Mekhoa ea ho Futhumatsa: Tshebetso e sebetsang hantle ho li-radiator le ho futhumatsa ka tlas'a fatše

- Sehatsetsing le ho Pholisa Moea: Phepelo e phahameng ea mocheso bakeng sa litsamaiso tsa ho pholisa

- Liphaephe tsa Khase ea Bongaka: Lipetlele li tšepa oksijene le likhase tsa bongaka

Qetello

Li-Tube tsa Koporo tsa Womic Steel tsa EN 1057 li fana ka boleng bo holimo, matla le ts'epo bakeng sa lits'ebetso tsa liphaephe, khase le indasteri. Boitlamo ba rona ba tlhahiso e nepahetseng, liteko tse matla le litharollo tse shebaneng le bareki bo re etsa hore re be molekane ea tšepahalang indastering.

Khetha Womic Steel Group e le molekane oa hau ea tšepahalang bakeng sa boleng bo holimoLiphaephe tsa Koporo&Lisebelisoa le ts'ebetso e sa hlōloeng ea ho tlisa thepa. Rea u amohela!

Webosaete: www.womicsteel.com

Imeile: sales@womicsteel.com

Mohala/WhatsApp/WeChat: Victor: +86-15575100681 kapa Jack: +86-18390957568

Nako ea poso: Hlakubele-10-2025