1. Kakaretso ea Sehlahisoa

Womic Steel ke moetsi ea tšepahalang oa liphaephe tsa koporo tsa boleng bo holimo tse lumellanang leASTM B88maemo a tloaelehileng, haholo-holoMofuta oa Llitlhaloso tse entsoeng kaC12200 (phosphorus e senyehileng, phosphorus e setseng e ngata)koporo. Liphaephe tsena tse thata tsa koporo li sebelisoa haholo holiphaephe, HVAC, tšireletso ea mollo, khase le litsamaiso tsa kakaretso tsa ts'ebelisoka lebaka la ho hanyetsa ha tsona mafome hantle, ho tšoarella le ho bopeha ha tsona habonolo.

Koporo ea C12200 e na le karolo e phahameng ea koporo e hloekileng le phosphorus e nyane, e ntlafatsang ho tjheseletsa ha eona le ho hanyetsa ho qhibiliha ha haeterojene. Liphaephe tsa mofuta oa L li na le tekano e ntle pakeng tsa botenya ba lebota le boima, li fana ka ts'epo lits'ebetsong tse ka holimo le tse ka tlas'a lefatše.

2. Mefuta ea Tlhahiso

- Bophara ba Kantle (OD):6 mm ho isa ho 219 mm

- Botenya ba lebota (boima):0.3 mm ho isa ho 10 mm

- Bolelele:Bolelele bo tloaelehileng ba3m, 5m, 6m, lebolelele bo ikhethileng bo fumaneha ha ho kopuoa

- Liphaephe tse kobehileng:E fumaneha kaLikhoele tsa 25m kapa 50mbakeng sa ho kenya ka mokhoa o tenyetsehang ka har'a li-heat exchanger

- Qetello ea ho Qetela:Qetello e se nang letho, e hloekisitsoeng le e hloekisitsoeng; e fumaneha ka likhurumetso kapa ntle le tsona

3. Mamello ea Dimensional (Li-Tube tsa Koporo tsa ASTM B88 C12200)

Tšepe ea Womic e netefatsa ho nepahala ho nepahetseng ha litekanyo bakeng saC12200lipeipi tse lumellanang leASTM B88maemo a amohelehileng. Ho na le maemo a latelang a mamello:

ASTM B88 - Tafole ea 1: Litekanyo, Boima, le Mamello bakeng sa Boholo ba Liphaephe tsa Metsi tsa Koporo

| Boholo bo Ikhethang (ka hare) | Bophara ba Kantle (ka hare) | Mamello ea OD (E Hlophisitsoe) | Mamello ea OD (E takiloe) | Lebota la Mofuta oa K (ka hare) | Mofuta oa K Tol. (ka hare) | Lebota la Mofuta oa L (ka hare) | Mofuta oa L Tol. (ka hare) | Lebota la Mofuta oa M (ka hare) | Mofuta wa M Tol. (ka hare) |

| 1/4 | 0.375 | 0.002 | 0.001 | 0.035 | 0.0035 | 0.03 | 0.003 | C | C |

| 3/8 | 0.5 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.035 | 0.004 | 0.025 | 0.002 |

| 1/2 | 0.625 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.04 | 0.004 | 0.028 | 0.003 |

| 5/8 | 0.75 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.042 | 0.004 | C | C |

| 3/4 | 0.875 | 0.003 | 0.001 | 0.065 | 0.006 | 0.045 | 0.004 | 0.032 | 0.003 |

| 1 | 1.125 | 0.0035 | 0.0015 | 0.065 | 0.006 | 0.05 | 0.005 | 0.035 | 0.004 |

| 1 1/4 | 1.375 | 0.004 | 0.0015 | 0.065 | 0.006 | 0.055 | 0.006 | 0.042 | 0.004 |

| 1 1/2 | 1.625 | 0.0045 | 0.002 | 0.072 | 0.007 | 0.06 | 0.006 | 0.049 | 0.005 |

| 2 | 2.125 | 0.005 | 0.002 | 0.083 | 0.008 | 0.07 | 0.007 | 0.058 | 0.006 |

| 2 1/2 | 2.625 | 0.005 | 0.002 | 0.095 | 0.01 | 0.08 | 0.008 | 0.065 | 0.006 |

| 3 | 3.125 | 0.005 | 0.002 | 0.109 | 0.011 | 0.09 | 0.009 | 0.072 | 0.007 |

| 3 1/2 | 3.625 | 0.005 | 0.002 | 0.12 | 0.012 | 0.1 | 0.01 | 0.083 | 0.008 |

| 4 | 4.125 | 0.005 | 0.002 | 0.134 | 0.013 | 0.11 | 0.011 | 0.095 | 0.01 |

| 5 | 5.125 | 0.005 | 0.002 | 0.160 | 0.016 | 0.125 | 0.012 | 0.109 | 0.011 |

| 6 | 6.125 | 0.005 | 0.002 | 0.192 | 0.019 | 0.14 | 0.014 | 0.122 | 0.012 |

| 8 | 8.125 | 0.008 | 0.002/-0.004 | 0.271 | 0.027 | 0.2 | 0.02 | 0.17 | 0.017 |

| 10 | 10.125 | 0.008 | 0.002/-0.006 | 0.338 | 0.034 | 0.25 | 0.025 | 0.212 | 0.021 |

| 12 | 12.125 | 0.008 | 0.002/-0.006 | 0.405 | 0.04 | 0.28 | 0.028 | 0.254 | 0.025 |

A Bophara bo tloaelehileng ba kantle ba tube ke karolelano ea bophara bo boholo le bo bonyane ba kantle, joalo ka ha ho khethoa karolong efe kapa efe ea tube.

B Phapang e kholo ka ho fetisisa ntlheng efe kapa efe.

C E bontša hore thepa ha e fumanehe ka kakaretso kapa hore ha ho na mamello e tiisitsoeng

Mamello ena e netefatsa hore lipeipi lia kopanaho nepahala ho hoholo le litlhoko tsa boleng, e leng se etsang hore li lokelelits'ebetso tse hlokang tlhokomelo ea indasteri le ea likepe.

3. Sebopeho sa Lik'hemik'hale (C12200 - ASTM B88)

Karolo Sebopeho (% ka boima)

Koporo (Cu) MinB≥ 99.9 (ho kenyeletsoa le silevera)

Fosforase (P) 0.015 – 0.040

Oksijene e lokela ho ba 10 ppm max.

B Koporo + silevera ≤ 0.04

Sekhahla sa phosphorus se ntlafatsa ho tjheseletsa le ho hanyetsa ho petsoha ha kgatello, ha ka nako e ts'oanang se boloka mocheso o phahameng le motlakase o tsamaisang motlakase.

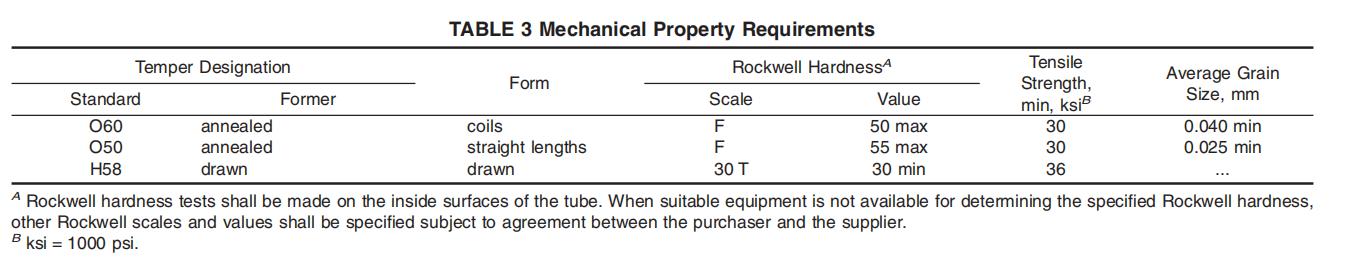

4. Thepa ea Mekaniki

Phaephe ea koporo e tiileng ea mofuta oa L hangata e fanoa ka mocheso o thata (o huloang), o loketseng litsamaiso tsa khatello le lits'ebetso tse otlolohileng.

5. Maemo a Phano

Womic Steel e fana ka liphaephe tsa koporo tsa Mofuta oa L maemong a latelang:

Bohale bo Matla (H58):Bolelele bo otlolohileng bakeng sa litsamaiso tsa khatello

Tempera e kopantsoeng (O60):E fumaneha ha ho kopuoa bakeng sa likopo tse hlokang ho kobeha le ho etsoa

6. Ts'ebetso ea Tlhahiso

Tšepe ea Womic e netefatsa ho nepahala le boleng bo holimo ka mehato e latelang:

- Ho Qhibilihisa le ho Lahla:Koporo e hloekileng haholo e qhibilihisoa ebe e lahleloa ka har'a li-billet.

- Ho ntša:Li-billet li ntšetsoa ka sebopeho sa tšubuhlellano.

- Setšoantšo se batang:Lipeipi li huloa ho ea ka boholo le botenya ba ho qetela.

- Ho annealing (ha ho hlokahale):Haeba ho hlokahala, e phekolwe ka mocheso bakeng sa bohale bo bonolo.

- Ho otlolla le ho Seha:Liphaephe li khaoloa ka bolelele bo tloaelehileng kapa bo ikhethileng.

- Ho Hloekisa le ho Hlahloba:Libaka tse ka hare le tse ka ntle lia hloekisoa le ho hlahlojoa.

- Ho tšoaea le ho paka:Liphaephe li tšoailoe ka ASTM B88, mofuta le boholo bakeng sa ho sala morao.

7. Teko le Tlhahlobo

Womic Steel e netefatsa maemo a boleng bo holimo ka ho etsatlhahlobo e matla le tlhahlobo, ho kenyeletsoa:

- Tlhahlobo ea Sebopeho sa Lik'hemik'hale:Netefatso e sebedisa tlhahlobo ya dikhemikhale tse metsi kapa tse nang le spectrographic

- Teko ea ho Tenyetseha:Ho netefatsa hore matla le bolelele li fihlela litlhoko tsa ASTM B88

- Teko ea ho tiea:E lekantsoe ho sebelisoaMokhoa oa Vickers

- Teko ea ho Atolosa ho Tsamaea ka Sekepe:Katoloso ea pheletso ea tube ka30%ho sebelisamandrel e kobehileng ea 45°

- Teko ea ho Batalatsa:Tlhahlobo eaho se fetohe le ho hanyetsa ho petsoha

- Teko ea Hona Joale ea Eddy (ECT):Ho fumanoa haliphoso tsa bokaholimo le bokatlase

- Teko ea Khatello ea Hydrostatic:Ho netefatsa hore lipeipi lia mamellakhatello ea ka hare ntle le ho dutla

8. Ho etsa disampole

Ho etsa disampole le ho etsa diteko ho etswa ho ya ka diprothokholo tsa ASTM B88 le tsa ka hare tsa QA. Disampole tsa diteko di kgethwa ka tsela e sa reroang ho tswa sehlopheng se seng le se seng bakeng sa:

l Dikahare tsa lik'hemik'hale

l Thepa ea mechini

Ho nepahala ha 1.5-dimensional

l Boemo ba holim'a metsi

9. Sephutheloana

Ho netefatsatsamaiso le lipalangoang tse bolokehileng, Womic Steel e fana kalitharollo tse matla tsa ho paka, ho kenyeletsoa:

- Sekoahelo sa ho Thibela ho Kena ha Oxidation:Lera le sireletsang le sebedisitsweng ho thibela ho bola nakong ya polokelo le phetisetso

- Li-cap tsa ho qetela:Likoahelo tsa polasetiki kapa tsa tšepe lipheletsong tsa lipeipi ho thibela tšilafalo

- Ho kopanya:Thapo e tiileng ka mabanta a polasetiki kapa a tšepe bakeng sa botsitso

- Sekoahelo sa Lehong:E pakiloe ka haremabokose a lehong a sa keneleng mongoboka lesela le sireletsang la foam

- Ho ngola mabitso:Sephutheloana se seng le se seng se ngotswe kaOD, WT, bolelele, bohale, nomoro ea sehlopha, le letsatsi la tlhahiso

10. Lipalangoang le Thepa

Womic Steel e netefatsathomello e nakong le e sireletsehilengka:

- Thepa ea Leoatleng:Sireletsehilethomello e nang le likhonteinara bakeng sa kabo ea lefats'e

- Lipalangoang tsa Terene le Litsela:Thomello e tšepahalang bakeng sa bareki ba libaka

- Tšebeliso e Ikhethang:Dikgetho tse laolwang ke tlelaemete bakeng sa ditshebediso tse hlokolosi

- Litokomane tse Felletseng:Ho kenyeletsoaLisetifikeiti tsa Teko ea Mill (MTC), Litlaleho tsa ho Latela Melao ea Lintho, le Inshorense

- Khanyetso e Phahameng ea Ts'enyeho:E ntle haholo bakeng salits'ebetso tsa phetisetso ea likepe, lik'hemik'hale le mocheso

- Tlhahiso e Nepahetseng:E tiilengmamello ea litekanyobakeng sa ts'ebetso e ntle ka ho fetisisa

- Litharollo tse Ikhethileng:Boholo, mocheso le masela a koahetsoeng a etselitsoeng litlhoko tse itseng

- Teko e Felletseng:Ho netefatsa hore ho latela melao ka botlaloASTM B88

- Marangrang a Kabo ea Lefatše:Phano e potlakileng le e tšepahalang lefatšeng ka bophara

11. Melemo ea ho Khetha Tšepe ea Basali

12. Likopo

Ea ronaASTM B88 C12200lipeipi li loketse bakeng sa:

- Indasteri ea Likepe: Li-condenser tse pholileng ka metsi a leoatle, liphaephe, le liphaephe tse fapanyetsanang mocheso ka har'a sekepe

- Limela tsa Motlakase:Li-condensers tsa mouoane lelitsamaiso tsa ho pholisa

- Limela tsa ho tlosa letsoai metsing:Liphaephe tse hanelang mafome bakeng sa ts'ebeliso ea metsi a letsoai

- Ts'ebetso ea Lik'hemik'hale:Liphaephe tsa phapanyetsano ea mocheso tse nang le khatello e phahameng le mocheso o phahameng

- HVAC le Sehatsetsing: Likhoele tsa moea o pholileng le litsamaiso tsa ho pholisa tsa indasteri

Qetello

Liphaephe tsa koporo tsa Womic Steel tsa ASTM B88 C12200 Type L li fana ka ts'ebetso e ikhethang, ho tšoarella le ho hanyetsa mafome, e leng se etsang hore e be khetho e ratoang bakeng sa mefuta e mengata ea litsamaiso tsa liphaephe. Ka ho khomarela ka tieo litekanyetso tsa ASTM le netefatso e felletseng ea boleng, re netefatsa hore phano e 'ngoe le e 'ngoe e fihlela litebello tse phahameng ka ho fetisisa ts'ebetsong le ts'epong.

Re motlotlo kalits'ebeletso tsa ho iketsetsa, lipotoloho tse potlakileng tsa tlhahisolenetweke ea lefats'e ea ho fana ka thepa, ho netefatsa hore litlhoko tsa hau tse ikhethileng li fihlelleha ka nepo le bokhabane.

Webosaete: www.womicsteel.com

Imeile: sales@womicsteel.com

Mohala/WhatsApp/WeChat: Victor: +86-15575100681 kapa Jack: +86-18390957568

Nako ea poso: Pherekhong-21-2026