Li-Flanges tsa Tšepe tse entsoeng ka motsoako o entsoeng ka tšepe ea ASTM A182, Lisebelisoa tse entsoeng ka motsoako o entsoeng ka tšepe le li-valve

ASTM A182 ke tlhaloso ea bohlokoa bakeng sa li-flange tsa tšepe tse entsoeng ka alloy kapa tse phutholohileng, li-fittings tse entsoeng ka alloy, le li-valve tse etselitsoeng ho sebelisoa libakeng tse nang le mocheso o phahameng le khatello e phahameng. Tekanyetso ena e fana ka litataiso bakeng sa motsoako oa lik'hemik'hale, thepa ea mechini, mekhoa ea liteko, le lintlha tse ling tsa bohlokoa tse netefatsang ho tšoarella le ho tšepahala ha likarolo tsena lits'ebetsong tsa bohlokoa.

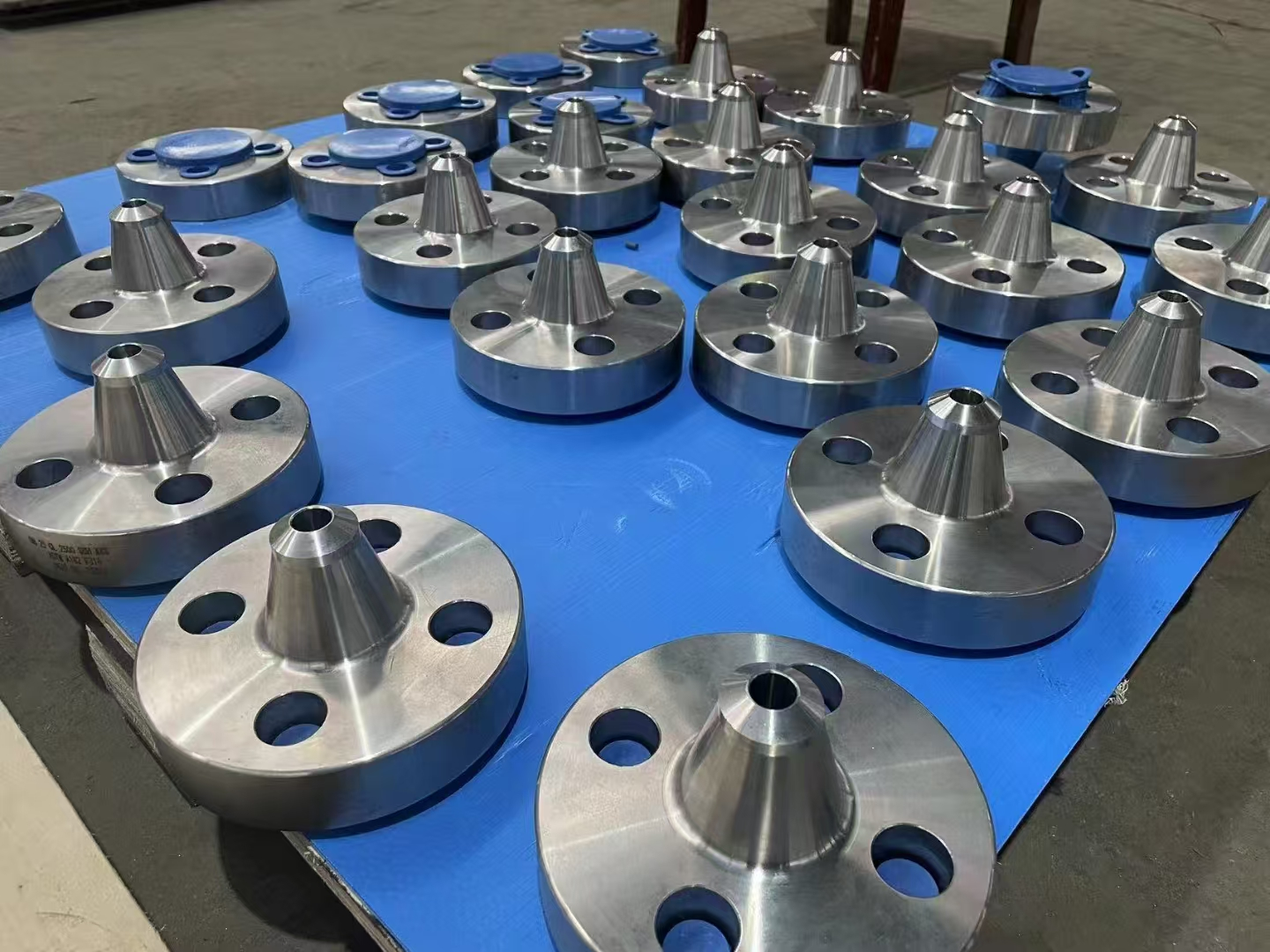

Ho Womic Steel, re hlahisa mefuta e mengata ea lihlahisoa tse khomarelang maemo a ASTM A182, re fana ka boleng bo holimo le ho nepahala. Sehloohong sena, re tla hlahloba lintlha tsa bohlokoa tsa maemo ana le ho bontša bokhoni ba tlhahiso ba Womic Steel le melemo ea ho re khetha re le mofani oa hau oa thepa.

Mefuta ea Lihlahisoa tse Akaretsoang ke ASTM A182

ASTM A182 e akaretsa likarolo tse fapaneng tsa tšepe tse entsoeng ka ho qhibilihisoa kapa tse phuthiloeng, ho kenyeletsoa:

1. Li-flange – Tsena li sebelisetsoa ho hokela liphaephe, li-valve, lipompo le lisebelisoa tse ling tsamaisong ea liphaephe.

2. Lisebelisoa tse entsoeng ka ho qhibilihisa – Tsena li kenyelletsa litsoe, li-tee, li-reducer, li-cap, le li-union tse sebelisoang lits'ebetsong tsa khatello e phahameng.

3. Li-valve - Li etselitsoe ho laola phallo ea metsi libakeng tse nang le mocheso o phahameng.

4. Lihlahisoa tse ling tse entsoeng ka ho qhibilihisoa kapa tse phuthoang – Tsena li kenyelletsa li-valve le li-fitting tse sebelisoang lits'ebetsong tsa mouoane, khase le tse ling tse nang le khatello e phahameng.

Ho Womic Steel, re hlahisa lintho tsena ka boholo, thepa le litlhophiso tse fapaneng, ho netefatsa hore li fihlela litlhoko tsa hau tse ikhethileng tsa kopo.

Lisebelisoa le Sebopeho sa Lik'hemik'hale

Tekanyetso ea ASTM A182 e totobatsa mefuta e 'maloa ea thepa, ho kenyeletsoa tšepe ea khabone, tšepe e nang le motsoako o tlase, le tšepe e sa ruseng, e 'ngoe le e 'ngoe e na le litlhoko tse ikhethang tsa sebopeho sa lik'hemik'hale. Tsena ke tse ling tsa lisebelisoa tsa bohlokoa tse koahetsoeng tlas'a ASTM A182:

1. Sehlopha sa F1 - Tšepe ea khabone e nang le motsoako o e lumellang ho sebetsa mochesong o itekanetseng.

2. Sehlopha sa F5, F9, F11, F22 – Litšepe tse nang le motsoako o tlaase tse etselitsoeng ho mamella mocheso le likhatello tse phahameng.

3. Sehlopha sa F304, F304L, F316, F316L – Litšepe tse sa hloekang tsa Austenitic, tse sebelisoang haholo bakeng sa ho hanyetsa ho bola ha tsona libakeng tse fapaneng tsa ts'ebetso ea lik'hemik'hale.

Bakeng sa sehlopha se seng le se seng, sebopeho sa lik'hemik'hale se laoloa ka hloko ho fihlela litlhoko tse thata tsa ASTM. Ka tlase ke lintlha tsa sebopeho sa lik'hemik'hale sa thepa ka 'ngoe le thepa ea eona.

Sebopeho sa Lik'hemik'hale le Thepa ea Mekaniki

1. Sehlopha sa F1 - Tšepe ea Khabone

Sebopeho sa Lik'hemik'hale:

Khabone (C): 0.30-0.60%

Manganese (Mn): 0.60-0.90%

Silicone (Si): 0.10-0.35%

Sebabole (S): ≤ 0.05%

Fosforase (P): ≤ 0.035%

Thepa ea Mekaniki:

Matla a ho Thanya (MPa): ≥ 485

Matla a Tlhahiso (MPa): ≥ 205

Ho lelefatsa (%): ≥ 20

2. Sehlopha sa F5 - Tšepe e Tlase ea Tšepe e se nang Motsoako

Sebopeho sa Lik'hemik'hale:

Khabone (C): 0.10-0.15%

Manganese (Mn): 0.50-0.80%

Chromium (Cr): 4.50-5.50%

Molybdenum (Mo): 0.90-1.10%

Sebabole (S): ≤ 0.03%

Fosforase (P): ≤ 0.03%

Thepa ea Mekaniki:

Matla a ho Thanya (MPa): ≥ 655

Matla a Tlhahiso (MPa): ≥ 345

Ho lelefatsa (%): ≥ 20

3. Sehlopha sa F304 - Tšepe e sa Hlakeng ea Austenitic

Sebopeho sa Lik'hemik'hale:

Khabone (C): ≤ 0.08%

Manganese (Mn): 2.00-2.50%

Chromium (Cr): 18.00-20.00%

Nikele (Ni): 8.00-10.50%

Sebabole (S): ≤ 0.03%

Fosforase (P): ≤ 0.045%

Thepa ea Mekaniki:

Matla a ho Thabisa (MPa): ≥ 515

Matla a Tlhahiso (MPa): ≥ 205

Ho lelefatsa (%): ≥ 40

4. Sehlopha sa F316 - Tšepe e sa Khaotseng ea Austenitic (E hanelang ho senyeha)

Sebopeho sa Lik'hemik'hale:

Khabone (C): ≤ 0.08%

Manganese (Mn): 2.00-3.00%

Chromium (Cr): 16.00-18.00%

Nikele (Ni): 10.00-14.00%

Molybdenum (Mo): 2.00-3.00%

Sebabole (S): ≤ 0.03%

Fosforase (P): ≤ 0.045%

Thepa ea Mekaniki:

Matla a ho Thabisa (MPa): ≥ 515

Matla a Tlhahiso (MPa): ≥ 205

Ho lelefatsa (%): ≥ 40

Litlhoko tsa Mekaniki le Tšusumetso

Litšobotsi tsa mechine tse kang matla a ho thapolla, matla a tlhahiso, le ho lelefala li bohlokoa bakeng sa ho netefatsa hore likarolo tse entsoeng ka mokhoa o ts'oanelang li sebetsa ka mokhoa o tšepahalang tlas'a khatello. ASTM A182 e totobatsa litšobotsi tsena bakeng sa sehlopha se seng le se seng sa thepa, 'me litlhoko li fapana ho latela maemo a ts'ebeliso.

Teko ea tšusumetsoke karolo e 'ngoe ea bohlokoa ea tekanyetso, e netefatsang hore likarolo tse entsoeng ka maiketsetso li ka mamella liphetoho tsa tšohanyetso mochesong kapa tšusumetsong. Mohlala, tekanyetso e ka 'na ea hloka teko ea Charpy V-notch ho netefatsa ho tiea maemong a mocheso o tlase.

Mekhoa ea Tlhahiso le Litlhoko tsa Kalafo ea Mocheso

Womic Steel e latela lits'ebetso tse thata tsa tlhahiso ho netefatsa hore lihlahisoa tsohle tsa ASTM A182 li fihlela maemo a boleng bo holimo ka ho fetisisa. Sena se kenyelletsa:

Ho Theha le ho Rola – Mechini ea rona ea sejoale-joale e netefatsa hore karolo e 'ngoe le e 'ngoe e entsoe kapa e phuthoa ho latela litekanyo le mamello e nepahetseng.

Kalafo ea Mocheso – Kalafo ea mocheso e bohlokoa bakeng sa ho fihlela litšobotsi tse lakatsehang tsa mechini. ASTM A182 e hloka lipotoloho tse itseng tsa kalafo ea mocheso ho latela sehlopha sa thepa, joalo ka ho annealing, ho tima le ho futhumatsa ho ntlafatsa ho tiea le matla.

Ho tjheseletsa – Re fana ka ditharollo tsa ho tjheseletsa tse ikgethileng bakeng sa dihlahiswa tsa ASTM A182, ho netefatsa dikgokelo tse tshepahalang, tse sa dutleng. Mekgwa ya ho tjheseletsa e laolwa ka hloko ho netefatsa hore dikarolo tse tjheseditsweng di kopana kapa di feta matla a thepa ya motheo.

Tlhahlobo le Teko

Re etsa mesebetsi e akaretsangtlhahlobo le litekoho netefatsa hore lihlahisoa tsohle li fihlela maemo a ASTM A182. Sena se kenyelletsa:

Litlhahlobo tse Bonahalang – Bakeng sa diphoso tsa bokaholimo kapa diphoso.

Teko e sa Senyeheng (NDT) – Ho kenyeletsoa le tlhahlobo ea ultrasound le tlhahlobo ea radiographic ho fumana liphoso tsa ka hare.

Teko ea Mechini – Matla a ho thapolla, matla a tlhahiso, le teko ea tšusumetso ho netefatsa ts'ebetso ea thepa tlas'a khatello.

Tlhahlobo ea Lik'hemik'hale – Ho netefatsa hore metsoako ea lik'hemik'hale e latela litlhaloso tsa maemo.

Lihlahisoa tsohle tsa rona li latela mekhoa e thata ea taolo ea boleng, 'me re fana ka litifikeiti tse qaqileng tsa ho latela melao bakeng sa odara e 'ngoe le e 'ngoe.

Litlhaloso tsa Sehlahisoa le Mefuta ea Boholo

At Tšepe ea Womic, re fana ka mefuta e mengata ea lihlahisoa tsa ASTM A182 ka boholo le litlhaloso tse fapaneng.boholo ba sebakae kenyeletsa:

Li-flange: Ho tloha ho 1/2" ho isa ho 60" ka bophara.

Li-Fittings tse entsoeng: Ho tloha ho 1/2" ho isa ho 48" ka bophara.

Li-valve: Boholo bo ikhethileng ho latela litlhoko tsa sistimi ea hau.

Lihlahisoa tsa rona li fumaneha ka litekanyetso le thepa e fapaneng ea khatello, ho netefatsa hore re ka fihlela litlhoko tse ikhethileng tsa projeke ea hau.

Melemo ea ho Paka, ho Romela le ho Tsamaisa

Re utloisisa bohlokoa ba ho tlisa thepa ka nako e nepahetseng le ka mokhoa o sireletsehileng. Litlhahiso tsa Womic Steelsephutheloana se ikhethilenge sireletsang botšepehi ba lihlahisoa nakong ea lipalangoang. Ebang ke ka ho romela thepa ka lik'hontheinara kapa litharollo tse khethehileng tsa thepa, re netefatsa hore odara ea hau e fihla ka nako ebile e le boemong bo phethahetseng.

Ea ronaboiphihlelo ba lipalangoangle likamano tse tobileng le lik'hamphani tsa ho romela thepa li re lumella ho fana ka litefiso tse hlōlisanang le litharollo tse tenyetsehang tsa ho romela thepa.

Ho iketsetsa le Litšebeletso tse ling

Ntle le mefuta e mengata ea lihlahisoa tse tloaelehileng, Womic Steel e fana katlhahiso e ikhethilengbakeng sa litlhoko tse ikhethang. Re ka fetola litekanyo, thepa le liphetho ho latela ts'ebeliso ea hau e ikhethileng.

Litšebeletso tsa Ts'ebetsokenyeletsa:

Ho etsa mechini – Bakeng sa diphetoho tse nepahetseng ho ya ka ditlhoko tsa hao.

Ho tjheseletsa – Bakeng sa dikgokelo kapa di-fitting tsa flange tse ikgethileng.

Litšebeletso tsa ho Koahela le ho Thibela ho Senyeha – Ho fana ka tšireletso e tšoarellang nako e telele ho latela litlhoko tsa hau tsa tikoloho.

Hobaneng o Lokela ho Khetha Tšepe ea Womic?

Bokgoni ba Tlhahiso: Re na le libaka tsa tlhahiso tsa sejoale-joale tse nang le bokhoni bo phahameng ba tlhahiso.

Botsebi ba TheknolojiSehlopha sa rona se entsoe ka baenjiniere le litsebi tse nang le boiphihlelo bo phahameng tse ikemiselitseng ho hlahisa lihlahisoa tsa boleng bo holimo.

Melemo ea Ketane ea Phepelo: Re na le likamano tse matla le bafepedi ba thepa e tala, re netefatsa hore thepa e tla tlisoa ka nako le melemo ea litšenyehelo.

Dikgetho tsa ho iketsetsa: Re fana ka ditharollo tse tenyetsehang ho fihlela ditlhoko tse ikgethang tsa projeke, ho kenyeletswa ho tjheseletsa, ho sebetsa ka machining le ho penta.

Qetello

TheTekanyetso ea ASTM A182e netefatsa botshepehi le tshebetso ya dihlahiswa tsa tshepe tse entsweng le tse phuthilweng ditshebedisong tsa bohlokwa. Womic Steel ke molekane wa hao ya tshepahalang bakeng sa dihlahiswa tsa boleng bo hodimo tse entsweng ho ya ka maemo ana, e fanang ka tshehetso e felletseng ho tloha ho ditlhaloso tsa tekheniki ho isa ho tsa thepa. Hore na o hloka boholo bo ikgethileng, ho tjheseletsa, kapa ho roka ka tsela e ikgethang, re fana ka ditharollo tse ikgethileng ho fihlela ditlhoko tsa hao, ho netefatsa tshebetso e phahameng le botshepehi ba ho fana ka thepa.

Webosaete: www.womicsteel.com

Imeile: sales@womicsteel.com

Mohala/WhatsApp/WeChat: Victor: +86-15575100681 kapa Jack: +86-18390957568

Nako ea poso: Mmesa-21-2025