Selelekela:

API 5L ke tlhaloso e tloaelehileng e thehiloeng ke American Petroleum Institute (API) bakeng sa liphaephe tsa tšepe tse se nang sekoli le tse tjhisitsoeng tse sebelisoang lits'ebetsong tsa lipalangoang ka har'a indasteri ea peterole le khase ea tlhaho. Womic Steel, moetsi ea ka sehloohong oa liphaephe tsa mela ea API 5L, e fana ka mefuta e felletseng ea lihlahisoa tse fihlelang limaraka le litlhaloso tse fapaneng. Sengoloa sena se fana ka papiso e qaqileng ea sebopeho sa lik'hemik'hale, thepa ea mechini, le maemo a liteko bakeng sa limaraka tse fapaneng tsa API 5L, ka bobeli PSL1 le PSL2 ho pholletsa le mefuta e meraro ea liphaephe: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), le SMLS (Seamless).

Bokgoni ba Tlhahiso le Mefuta:

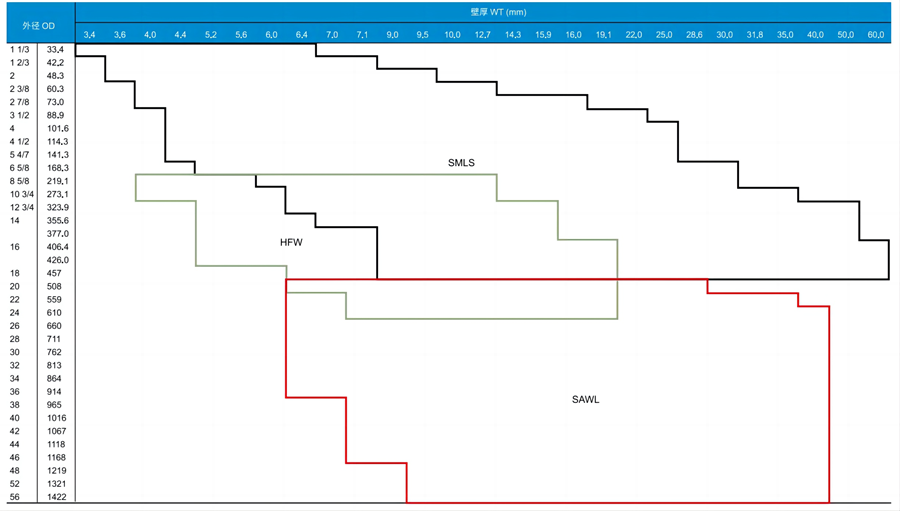

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Bonyane mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| SMLS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Mamello ea Bophara ba Kantle

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| TLHOKOMELISO EA API SO 3183 | D<60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ± 2.0mm | ± 1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Ela Hloko: D ke bophara bo tloaelehileng ba kantle ba phaephe.

Mamello ea Botenya ba Lebota

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| TLHOKOMELISO EA API ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | + 10%/-10% | ||

| - | 15.0mmst<25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t<30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t<37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

Tlhahlobo ea Lik'hemik'hale

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | Pcm | 备注 |

| boholo | boholo | boholo | boholo | boholo | boholo | boholo | boholo | boholo | boholo | |||||

| TLHOKOMELISO EA API 5L | 无缝管 | PSL1 | L210 kapa A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 kapa B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 kapa X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 kapa X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 kapa X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 kapa X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 kapa X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 kapa X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L485 kapa X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N kapa BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | CFO | ||

| L290N kapa X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N kapa X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N kapa X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N kapa X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N kapa X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Joalokaha ho lumellanoe | d,g,o | ||||

| L245Q kapa BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q kapa X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q kapaX46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 kapa ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q kapa X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q kapa X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450Q kapa X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485Q kapa X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555Q kapa X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Joalokaha ho lumellanoe | h, ke | ||||

| 酸性服 | L245NS kapa BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| L290NS kapa X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS kapa X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| L360NS kapa X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| L245QS kapa BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS kapa X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS kapa X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS kapa X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| L390QS kapa X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| L415QS kapa X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS kapa X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| L485QS kapa X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | Pcm | 备注 |

| boholo | boholo | boholo | boholo | boholo | boholo | boholo | boholo | boholo | boholo | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO kapa BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d,I,m |

| L290NO kapa X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO kapa X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d, Ke, m | |||

| L360NO kapa X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,I | |||

| L245QO kapa BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO kapa X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO kapa X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO kapa X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| L390QO kapa X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| L415QO kapa X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| L455QO kapa X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 kapa X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| L555QO kapa X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Joalokaha ho lumellanoe | d,I,n | ||||

| 焊管 | PSL1 | L245 kapa B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 kapaX42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 kapaX46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 kapa X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 kapaX56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 kapaX60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 kapa X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 kapa X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M kapa BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M kapa X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M kapa X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M kapa X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L390M kapa X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M kapa X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450M kapa X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M kapa X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555M kapa X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | Pcm | 备注 |

| boholo | boholo | boholo | boholo | boholo | boholo | boholo | boholo | boholo | boholo | |||||

| TLHOKOMELISO EA API 5L | 焊管 | 酸性服 | L245MS kapa BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS kapa X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS kapa X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS kapa X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS kapa X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| L415MS kapa X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| L450MS kapa X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| L485MS kapa X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO kapa BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO kapa X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO kapa X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Ke, m | |||

| L360MO kapa X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| L390MO kapa X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO kapa X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| L450MO kapa X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO kapa X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| L555MO kapa X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| TLHOKOMELISO EA API 5L | PSL1 | L210 kapa A | Bonyane | 210 | 335 | a |

| 335 |

| L245 kapa B | Bonyane | 245 | 415 | a |

| 415 | ||

| L290 kapa X42 | Bonyane | 290 | 415 | a |

| 415 | ||

| L320 kapa X46 | Bonyane | 320 | 435 | a |

| 435 | ||

| L360 kapa X52 | Bonyane | 360 | 460 | a |

| 460 | ||

| L390 kapa X56 | Bonyane | 390 | 490 | a |

| 490 | ||

| L415 kapa X60 | Bonyane | 415 | 520 | a |

| 520 | ||

| L450 kapa X65 | Bonyane | 450 | 535 | a |

| 535 | ||

| L485 kapa X70 | Bonyane | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N kapa BN | Bonyane | 245 | 415 | a |

| 415 | |

| Boholo | 450 | 655 |

| 0.93 |

| |||

| L290N kapa X42N | Bonyane | 290 | 415 | a |

| 415 | ||

| Boholo | 495 | 655 |

| 0.93 |

| |||

| L320N kapa X46N | Bonyane | 320 | 435 | a |

| 435 | ||

| Boholo | 525 | 655 |

| 0.93 |

| |||

| L360N kapa X52N | Bonyane | 360 | 460 | a |

| 460 | ||

| Boholo | 530 | 760 |

| 0.93 |

| |||

| L390N kapa X56N | Bonyane | 390 | 490 | a |

| 490 | ||

| Boholo | 545 | 760 |

| 0.93 |

| |||

| L415N kapa X60N | Bonyane | 415 | 520 | a |

| 520 | ||

| Boholo | 565 | 760 |

| 0.93 |

| |||

| L450Q kapa X65Q | Bonyane | 450 | 535 | a |

| 535 | ||

| Boholo | 600 | 760 |

| 0.93 |

| |||

| L485Q kapa X70Q | Bonyane | 485 | 570 | a |

| 570 | ||

| Boholo | 635 | 760 |

| 0.93 |

| |||

| L555Q kapa X80Q | Bonyane | 555 | 625 | a |

| 625 | ||

| Boholo | 705 | 825 |

| 0.93 |

| |||

| L625M kapa X90M | Bonyane | 625 | 695 | a |

| 695 | ||

| Boholo | 775 | 915 |

| 0.95 |

| |||

| L690M kapa X100M | Bonyane | 690 | 760 | a |

| 760 | ||

| Boholo | 840 | 990 |

| 0.97 |

| |||

| L830M kapa X120M | Bonyane | 830 | 915 | a |

| 915 | ||

| Boholo | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| TLHOKOMELISO EA API 5L | 酸性服 | L245NS kapa BNS | Bonyane | 245 | 415 | a |

| 415 |

| Boholo | 450 | 655 |

| 0.93 |

| |||

| L290NS kapa X42NS | Bonyane | 290 | 415 | a |

| 415 | ||

| Boholo | 495 | 655 |

| 0.93 |

| |||

| L320NS kapa X46NS | Bonyane | 320 | 435 | a |

| 435 | ||

| Boholo | 525 | 655 |

| 0.93 |

| |||

| L360NS kapa X52NS | Bonyane | 360 | 460 | a |

| 460 | ||

| Boholo | 530 | 760 |

| 0.93 |

| |||

| L390QS kapa X56QS | Bonyane | 390 | 490 | a |

| 490 | ||

| Boholo | 545 | 760 |

| 0.93 |

| |||

| L415QS kapa X60QS | Bonyane | 415 | 520 | a |

| 520 | ||

| Boholo | 565 | 760 |

| 0.93 |

| |||

| L450QS kapa X65QS | Bonyane | 450 | 535 | a |

| 535 | ||

| Boholo | 600 | 760 |

| 0.93 |

| |||

| L485QS kapa X70QS | Bonyane | 485 | 570 | a |

| 570 | ||

| Boholo | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO kapa BNO | Bonyane | 245 | 415 | a | - | 415 | |

| Boholo | 450 | 655 |

| 0.93 |

| |||

| L290NO kapa X42NO | Bonyane | 290 | 415 | a |

| 415 | ||

| Boholo | 495 | 655 |

| 0.93 |

| |||

| L320NO kapa X46NO | Bonyane | 320 | 435 | a |

| 435 | ||

| Boholo | 520 | 655 |

| 0.93 |

| |||

| L360NO kapa X52NO | Bonyane | 360 | 460 | a |

| 460 | ||

| Boholo | 525 | 760 |

| 0.93 |

| |||

| L390QO kapa X56QO | Bonyane | 390 | 490 | a |

| 490 | ||

| Boholo | 540 | 760 |

| 0.93 |

| |||

| L415QO kapa X60QO | Bonyane | 415 | 520 | a | - | 520 | ||

| Boholo | 565 | 760 |

| 0.93 |

| |||

| L450QO kapa X65QO | Bonyane | 450 | 535 | a | - | 535 | ||

| Boholo | 570 | 760 |

| 0.93 |

| |||

| L485Q0 kapa X70Q0 | Bonyane | 485 | 570 | a |

| 570 | ||

| Boholo | 605 | 760 |

| 0.93 |

| |||

| L555QO kapa X80QO | Bonyane | 555 | 625 | a |

| 625 | ||

| Boholo | 675 | 825 |

| 0.93 |

Hlokomela: a: Bolelele bo bonyane bo sebediswang equation e latelang: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D<1422mm | D=1422mm | |

| ≤L415 kapa X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415 kapa X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 kapa X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 kapa X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Ela Hloko: (1) Boleng bo tafoleng bo loketse sampole e tloaelehileng ea boholo bo felletseng.

(2) Boleng bo ka hare ho bracket ke boleng bo bonyane ba le le leng, bracket e ka ntle ke boleng bo tloaelehileng.

(3) Teko ea Mocheso: 0°C.

Maemo a Teko:

Liphaephe tsa mohala tsa API 5L tse entsoeng ke Womic Steel li etsoa liteko tse matla ho netefatsa hore li fihlela maemo a boleng bo holimo ka ho fetisisa. Maemo a liteko a kenyelletsa:

Tlhahlobo ea Lik'hemik'hale:

Sebopeho sa lik'hemik'hale sa tšepe se hlahlojoa ho netefatsa hore se fihlela litlhoko tsa tlhaloso ea API 5L.

Tlhahlobo ea lik'hemik'hale e etsoa ho sebelisoa spectrometer ea ho bala ka ho toba ho fumana ka nepo sebopeho sa motheo sa tšepe.

Teko ea Mekaniki:

Litšobotsi tsa mechine tse kang matla a tlhahiso, matla a ho tsikinyeha le ho lelefala lia lekoa ho netefatsa hore li fihlela litlhoko tse boletsoeng.

Teko ea mechini e etsoa ho sebelisoa mochini oa teko ea ho thaepa oa lithane tse 60 ho lekanya matla le ho potlaka ha tšepe.

Teko ea Hydrostatic:

Teko ea hydrostatic e etsoa ho hlahloba botšepehi ba phaephe le ho netefatsa hore e khona ho mamella litlhoko tsa khatello tsa ts'ebeliso ea eona e reriloeng.

Liphaephe li tlatsoa ka metsi 'me li tlas'a khatello, ka nako ea teko le maemo a khatello a boletsoeng ke maemo a API 5L.

Teko e sa Senyeheng (NDT):

Mekhoa ea NDT e kang tlhahlobo ea ultrasound (UT) le tlhahlobo ea likaroloana tsa makenete (MT) e sebelisoa ho lemoha liphoso kapa ho se tsoele pele ha phaephe.

UT e sebelisetsoa ho lemoha mefokolo ea ka hare, ha MT e sebelisetsoa ho lemoha mefokolo ea bokaholimo.

Teko ea Tšusumetso:

Teko ea tšusumetso e etsoa ho lekola ho tiea ha tšepe mochesong o tlase.

Teko ea tšusumetso ea Charpy e sebelisoa hangata ho lekanya matla a tšusumetso a monngoang ke tšepe.

Teko ea ho tiea:

Teko ea ho thatafala e etsoa ho lekola ho thatafala ha tšepe, e leng se ka bontšang matla a eona le ho tšoaneleha ha eona bakeng sa lits'ebetso tse itseng.

Teko ea ho thatafala ha Rockwell hangata e sebelisoa ho lekanya ho thatafala ha tšepe.

Tlhahlobo ea Sebopeho sa Micro:

Tlhahlobo ea sebopeho sa microstructure e etsoa ho lekola sebopeho sa lijo-thollo le boleng ba tšepe ka kakaretso.

Microscope ea tšepe e sebelisoa ho hlahloba sebopeho sa tšepe le ho fumana lintho tse sa tloaelehang.

Ka ho latela maemo ana a thata a teko, Womic Steel e netefatsa hore liphaephe tsa eona tsa mohala tsa API 5L li fihlela litlhoko tsa boleng bo holimo 'me li fana ka ts'ebetso e tšepahalang lits'ebetsong tse fapaneng tsa indasteri.

Tshebetso ea Tlhahiso:

1. Liphaephe tsa Tšepe tse se nang Seam:

- Khetho ea Thepa e Tala: Li-billet tsa tšepe tse chitja tsa boleng bo holimo li khethoa bakeng sa tlhahiso ea liphaephe tsa tšepe tse se nang mohele.

- Ho Futhumatsa le ho Phunya: Li-billet li futhumatsoa mochesong o phahameng ebe lia phunyeletsoa ho etsa khetla e se nang letho.

- Ho phutholoha le ho Saese: Khetla e phuthoang e ntoo phutholoha le ho otlollwa ho fihlela bophara le botenya bo lakatsehang.

- Kalafo ea Mocheso: Liphaephe li kenngoa lits'ebetsong tsa kalafo ea mocheso tse kang ho annealing kapa ho normalize ho ntlafatsa litšobotsi tsa tsona tsa mechini.

- Ho Qetella: Liphaephe li feta lits'ebetsong tsa ho qetela tse kang ho otlolla, ho seha le ho hlahlojoa.

- Teko: Liphaephe li feta litekong tse fapaneng, ho kenyeletsoa le liteko tsa hydrostatic, liteko tsa ultrasound, le liteko tsa eddy current, ho netefatsa boleng ba tsona.

- Kalafo ea Bokaholimo: Liphaephe li ka 'na tsa koaheloa kapa tsa phekoloa ho thibela ho bola le ho ntlafatsa ponahalo ea tsona.

- Ho paka le ho Romela: Liphaephe li phutheloa ka hloko 'me li romelloa ho bareki.

2. Liphaephe tsa Tšepe tsa LSAW (Longitudinal Submerged Arc Welding):

- Tokiso ea Lipoleiti: Lipoleiti tsa tšepe tsa boleng bo holimo li lokisetsoa tlhahiso ea liphaephe tsa LSAW.

- Ho theha: Lipoleiti li etsoa ka sebopeho sa "U" ho sebelisoa mochini o kobehang pele.

- Ho tjheseletsa: Dipoleiti tse bōpehileng joaloka "U" li kopanngoa hammoho ho sebelisoa mokhoa oa ho tjheseletsa oa arc o qoelitsoeng ka metsing.

- Katoloso: Sehokelo se tjhitilweng se atoloswa ho fihlela bophara bo lakatsehang ho sebediswa mochini o atoloswang ka hare kapa kantle.

- Tlhahlobo: Liphaephe li hlahlojoa bakeng sa liphoso le ho nepahala ha litekanyo.

- Teko ea Ultrasonic: Liphaephe li etsoa liteko tsa ultrasound ho fumana liphoso leha e le life tsa ka hare.

- Ho betla: Lipheletso tsa phaephe li betla bakeng sa ho tjheseletsa.

- Ho Koahela le ho Tšoaea: Liphaephe li ka koaheloa le ho tšoauoa ho latela litlhoko tsa bareki.

- Ho paka le ho Romela: Liphaephe lia pakoa le ho romelloa ho bareki.

3. Liphaephe tsa Tšepe tsa HFW (Ho Welding ka Maqhubu a Phahameng):

- Ho Lokisetsa Khoele: Likhoele tsa tšepe li lokisetsoa tlhahiso ea liphaephe tsa HFW.

- Ho theha le ho tjheseletsa: Dikhoele di bopjwa ka sebopeho sa cylindrical ebe di tjheseletsa ka ho sebedisa ho tjheseletsa ka maqhubu a phahameng.

- Ho Futhumatsa Seam sa Weld: Seam sa weld se futhumatsoa ho fihlela mochesong oa welding ho sebelisoa ho futhumatsa ha induction khafetsa.

- Saese: Phaephe e tjheseditsweng e boholo bo lekanang le bophara le botenya bo hlokahalang.

- Ho Seha le ho Beveling: Phaephe e sehiloe ka bolelele bo lakatsehang mme dipheletso di beveling bakeng sa ho tjheseletsa.

- Tlhahlobo: Liphaephe li hlahlojoa bakeng sa liphoso le ho nepahala ha litekanyo.

- Teko ea Hydrostatic: Liphaephe li lekoa bakeng sa matla le ho lutla ho sebelisoa teko ea hydrostatic.

- Ho Koahela le ho Tšoaea: Liphaephe li koahetsoe 'me li tšoailoe ho latela litlhoko tsa bareki.

- Ho paka le ho Romela: Liphaephe lia pakoa le ho romelloa ho bareki.

Mekhoa ena e qaqileng ea tlhahiso e netefatsa boleng bo holimo le botšepehi ba liphaephe tsa tšepe tse se nang sekoli, tsa LSAW, le tsa HFW tse entsoeng ke Womic Steel, tse fihlelang litlhoko tse thata tsa liindasteri tse fapaneng.

Kalafo ea Bokaholimo:

Kalafo ea bokaholimo ba tšepe ea liphaephe e bohlokoa bakeng sa ho ntlafatsa khanyetso ea eona ea mafome le bophelo ba ts'ebeletso. Womic Steel e sebelisa mekhoa e fapaneng ea kalafo ea bokaholimo ho latela litlhoko tse fapaneng tse tsoang ho bareki, ho kenyeletsoa:

1. Ho kenya Galvanizing ka ho Chesa: Phaephe ya tshepe e qoelisoa ka hara zinki e qhibilihisitsweng ho etsa lera le sireletsang motsoako wa zinki le tshepe, e leng se eketsang ho hanyetsa ha yona mafome. Ho kenya Galvanizing ka ho Chesa ho loketse diphaephe tsa setso le tse nang le kgatello e tlase.

2. Liaparo tse thibelang ho bola: Liaparo tse tloaelehileng tse thibelang ho bola li kenyelletsa liaparo tsa epoxy, liaparo tsa polyethylene, le liaparo tsa polyurethane. Liaparo tsena li thibela oxidation le mafome ka katleho holim'a phaephe ea tšepe, li lelefatsa bophelo ba eona ba ts'ebeletso.

3. Ho phatloha ha lehlabathe: Ho phatloha ka lebelo le phahameng ho sebediswa ho hlwekisa phaephe ya tshepe, ho tlosa mafome le ditshila hodima metsi, ho fana ka motheo o motle bakeng sa kalafo e latelang ya ho roala.

4. Kalafo ea ho Koahela: Bokaholimo ba phaephe ea tšepe bo ka koaheloa ka pente e thibelang ho bola, pente ea asphalt, le lipente tse ling ho ntlafatsa ho hanyetsa ha eona ho bola, e loketseng liphaephe tse ka tlas'a lefatše le liphaephe libakeng tsa leoatle.

Mekhoa ena ea ho phekola bokaholimo e sireletsa tšepe ea liphaephe ka katleho ho senyeheng le ho senyeheng, e netefatsa ho tšepahala ha eona le ho tšoarella ha eona libakeng tse fapaneng tse thata.

Sephutheloana le Lipalangoang:

Womic Steel e netefatsa sephutheloana se sireletsehileng le tsamaiso e tšepahalang ea tšepe ea lipeipi, e fana ka likhetho tse tenyetsehang ho fihlela litlhoko tse fapaneng tsa bareki:

1. Thepa e Kgolo: Bakeng sa diotara tse kgolo, tshepe ya diphaephe e ka romelwa ka bongata ho sebediswa dijari tse ikgethang tsa thepa e kgolo. Tshepe e kenngwa ka ho toba ka hara sekepe ntle le ho paka, e loketse ho tsamaiswa ka bongata bo bongata ka theko e tlase.

2. LCL (Mojaro o ka Tlase ho Setshelo): Bakeng sa diotara tse nyane, tshepe ya phaephe e ka romelwa e le thepa ya LCL, moo diotara tse ngata tse nyane di kopanngwang setshelong se le seng. Mokgwa ona o theko e tlase bakeng sa bongata bo bonyenyane mme o fana ka dikemiso tse tenyetsehang tsa ho tlisa thepa.

3. FCL (Mojaro o Felletseng wa Setshelo): Bareki ba ka kgetha ho romelwa ha FCL, moo setshelo se felletseng se nehetsweng ho odara ya bona. Mokgwa ona o fana ka dinako tse potlakileng tsa ho tsamaisa thepa mme o fokotsa kotsi ya tshenyo nakong ya ho e tshwara.

4. Thepa ea Moeeng: Bakeng sa liodara tse potlakileng, thepa ea moeeng e fumaneha bakeng sa ho romelloa ka potlako. Le hoja e le theko e boima ho feta thepa ea leoatleng, thepa ea moeeng e fana ka lipalangoang tse potlakileng le tse tšepahalang bakeng sa thepa e amang nako.

Womic Steel e netefatsa hore thepa eohle e romelloang e phuthetsoe ka mokhoa o sireletsehileng ho thibela tšenyo nakong ea lipalangoang. Hangata tšepe e phuthetsoe ka thepa e sireletsang 'me e tiisitsoe ka har'a lijana kapa liphaleteng ho netefatsa botsitso nakong ea lipalangoang. Ho feta moo, k'hamphani e sebetsa haufi-ufi le balekane ba tšepahalang ba likepe ho netefatsa hore thepa e romelloang ka nako e loketseng le tsamaiso e sebetsang ea thepa.

Maemo a Kopo:

Liphaephe tsa mohala tsa API 5L tse hlahisoang ke Womic Steel li sebelisoa haholo indastering ea peterole le khase ea tlhaho bakeng sa ho tsamaisa oli, khase le maro a mang. Li boetse li sebelisoa indastering e meng e fapaneng e kang ts'ebetso ea lik'hemik'hale, tlhahiso ea motlakase le kaho.

Qetello:

Womic Steel ke moetsi ea tšepahalang oa liphaephe tsa mohala tsa API 5L, o fanang ka lihlahisoa tsa boleng bo holimo tse fihlelang litlhoko tse thata tsa indasteri ea peterole le khase ea tlhaho. Ka ho shebana le boleng, botšepehi le khotsofalo ea bareki, Womic Steel e ntse e le khetho e ratoang bakeng sa bareki lefatšeng ka bophara.

Nako ea poso: Hlakubele-22-2024