Tlhaloso ea Sehlahisoa

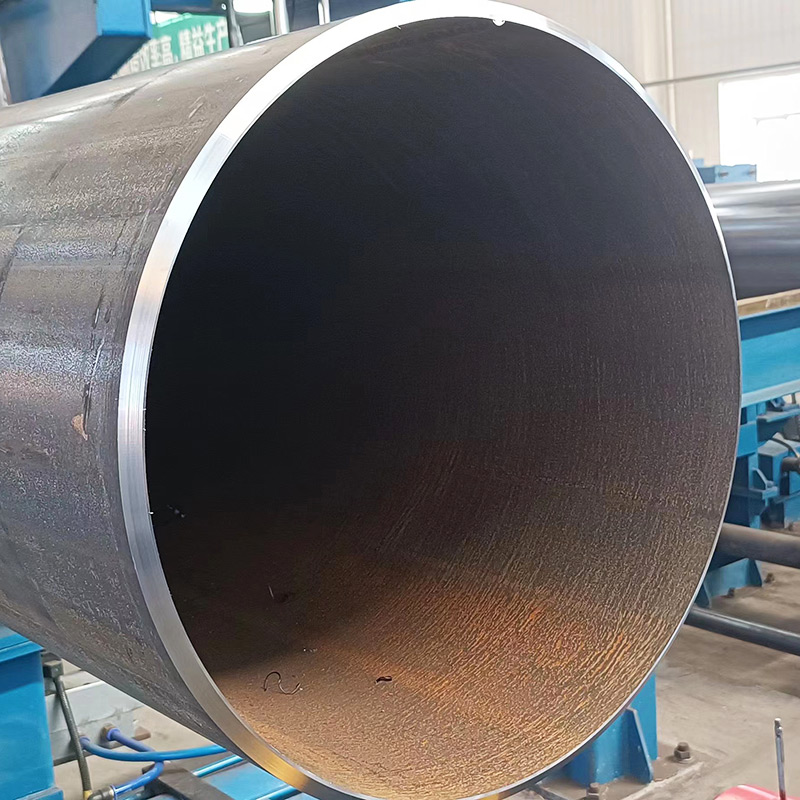

Liphaephe tsa tšepe tsa LSAW (Longitudinal Submerged Arc Welding) ke mofuta oa phaephe ea tšepe e bōpehileng joaloka thapo e nang le ts'ebetso ea eona e ikhethang ea tlhahiso le mefuta e mengata ea lits'ebetso. Liphaephe tsena li etsoa ka ho etsa poleiti ea tšepe ka sebopeho sa cylindrical le ho e tjheseletsa ka bolelele ho sebelisoa mekhoa ea ho tjheseletsa ea arc e qoelitsoeng. Mona ke kakaretso ea liphaephe tsa tšepe tsa LSAW:

Mokhoa oa Tlhahiso:

● Tokiso ea Lipoleiti: Lipoleiti tsa tšepe tsa boleng bo holimo li khethoa ho latela litlhoko tse itseng, ho netefatsa litšobotsi tse lakatsehang tsa mechini le motsoako oa lik'hemik'hale.

● Ho Theha: Poleiti ea tšepe e bōpehile joaloka phaephe e chitja ka mekhoa e kang ho kobeha, ho phutholla, kapa ho hatella (JCOE le UOE). Meeli e kobehile esale pele ho nolofatsa ho tjheseletsa.

● Ho tjheseletsa: Ho tjheseletsa arc e kentsweng ka metsing (SAW) ho sebediswa, moo arc e bolokwang tlasa lera la flux. Sena se hlahisa di-weld tsa boleng bo hodimo tse nang le diphoso tse fokolang le ho kopanngwa ho hotle haholo.

● Tlhahlobo ea Ultrasonic: Kamora ho tjheseletsa, ho etsoa liteko tsa ultrasound ho fumana liphoso leha e le life tsa ka hare kapa tsa kantle sebakeng sa tjheseletsa.

● Ho Atolosa: Phaephe e ka atolosoa ho fihlela bophara bo lakatsehang le botenya ba lebota, e leng se ntlafatsang ho nepahala ha litekanyo.

● Tlhahlobo ea ho Qetela: Teko e felletseng, ho kenyeletsoa le tlhahlobo ea pono, liteko tsa boholo, le liteko tsa thepa ea mechini, li netefatsa boleng ba phaephe.

Melemo:

● Ho Boloka Litšenyehelo: Liphaephe tsa LSAW li fana ka tharollo e theko e tlaase bakeng sa liphaephe tse bophara bo boholo le lits'ebetso tsa meaho ka lebaka la ts'ebetso ea tsona e sebetsang ea tlhahiso.

● Matla a Phahameng: Mokhoa oa ho tjheseletsa o molelele o fella ka liphaephe tse nang le thepa e matla le e ts'oanang ea mechini.

● Ho Nepahala ha Dikarolo: Diphaephe tsa LSAW di bontsha dibopeho tse nepahetseng, e leng se etsang hore di lokele ditshebediso tse nang le mamello e tiileng.

● Boleng ba ho Weld: Ho weld ea arc e qoelitsoeng ka metsing ho hlahisa li-weld tsa boleng bo holimo tse nang le motsoako o motle le liphoso tse fokolang.

● Ho Feto-fetoha ha Metsi: Liphaephe tsa LSAW li sebelisoa liindastering tse fapaneng, ho kenyeletsoa oli le khase, kaho le phepelo ea metsi, ka lebaka la ho ikamahanya le maemo le ho tšoarella ha tsona.

Ka bokhutšoanyane, liphaephe tsa tšepe tsa LSAW li etsoa ka mokhoa o nepahetseng le o sebetsang hantle, e leng se fellang ka liphaephe tse feto-fetohang, tse theko e tlaase, le tse tšoarellang tse loketseng mefuta e mengata ea lits'ebetso tsa indasteri.

Litlhaloso

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Kereiti C250, Kereiti C350, Kereiti C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

Mefuta ea Tlhahiso

| Bophara ba Kantle | Botenya ba lebota bo fumaneha bakeng sa sehlopha se ka tlase ho tšepe | |||||||

| Senthimithara | mm | Kereiti ea Tšepe | ||||||

| Senthimithara | mm | L245(Gr.B) | L290(X42) | L360(X52) | L415(X60) | L450(X65) | L485(X70) | L555(X80) |

| 16 | 406 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 18 | 457 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 20 | 508 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 22 | 559 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 24 | 610 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 26 | 660 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 28 | 711 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 30 | 762 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 32 | 813 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 34 | 864 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 36 | 914 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 38 | 965 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 40 | 1016 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 42 | 1067 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 44 | 1118 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 46 | 1168 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 48 | 1219 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 52 | 1321 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 56 | 1422 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 60 | 1524 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 64 | 1626 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 68 | 1727 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 72 | 1829 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

* Boholo bo bong bo ka fetoloa kamora ditherisano

Sebopeho sa Lik'hemik'hale le Thepa ea Mekaniki ea Pipe ea Tšepe ea LSAW

| E tloaelehileng | Sehlopha | Sebopeho sa Lik'hemik'hale (max)% | Thepa ea Mekaniki (metsotso) | |||||

| C | Mn | Si | S | P | Matla a Tekanyo (Mpa) | Matla a ho Tenyetseha (Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS EN10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

| SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Maemo le Kereiti

| E tloaelehileng | Likereiti tsa Tšepe |

| API 5L: Tlhaloso bakeng sa Pipe ea Mohala | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Tlhaloso e Tloaelehileng bakeng sa Liqubu tsa Liphaephe tsa Tšepe tse Welded le tse se nang Seamless | GR.1, GR.2, GR.3 |

| EN 10219-1: Likarolo tse nang le sekoti tse entsoeng ka mokhoa o batang tsa litšepe tse seng tsa motsoako le tsa lijo-thollo tse ntle | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Likarolo tse Chesang tse Felletseng tsa Meaho tse sa Tšoarellang le tsa Litšepe tse Ntle tsa Koro | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Phaephe, Tšepe, E Ntšo le e Chesang, e Koahetsoeng ka Zinki, e Welded le e se nang Seamless | GR.A, GR.B |

| EN10208: Liphaephe tsa tšepe tse sebelisoang lits'ebetsong tsa lipalangoang tsa liphaephe indastering ea peterole le khase ea tlhaho. | L210GA, L235GA, L245GA, L290GA, L360GA |

| EN 10217: Liphaephe tsa Tšepe tse Welded bakeng sa Merero ea Khatello | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Liphaephe tsa Tšepe tse Welded le Liphaephe | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Tekanyetso ea Australia/New Zealand bakeng sa Likarolo tsa Tšepe ea Meaho e entsoeng ka Batang | Sehlopha sa C250, Sehlopha sa C350, Sehlopha sa C450 |

| GB/T 9711: Liindasteri tsa Petroleum le Khase ea Tlhaho - Pipe ea Tšepe bakeng sa Liphaephe | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| ASTM A671: Pipe ea Tšepe e Welded ka Motlakase bakeng sa Mocheso o Chesang oa Sepakapaka le o Tlase | CA 55, CB 60, CB 65, CB 70, CC 60, CC 65, CC 70 |

| ASTM A672: Phaephe ea tšepe e kopantsoeng ka motlakase bakeng sa tšebeletso ea khatello e phahameng mochesong o itekanetseng. | A45, A50, A55, B60, B65, B70, C55, C60, C65 |

| ASTM A691: Phaephe ea tšepe ea khabone le motsoako, e kopantsoeng ka motlakase bakeng sa tšebeletso ea khatello e phahameng mochesong o phahameng. | CM-65, CM-70, CM-75, 1/2CR-1/2MO, 1CR-1/2MO, 2-1/4CR, 3CR |

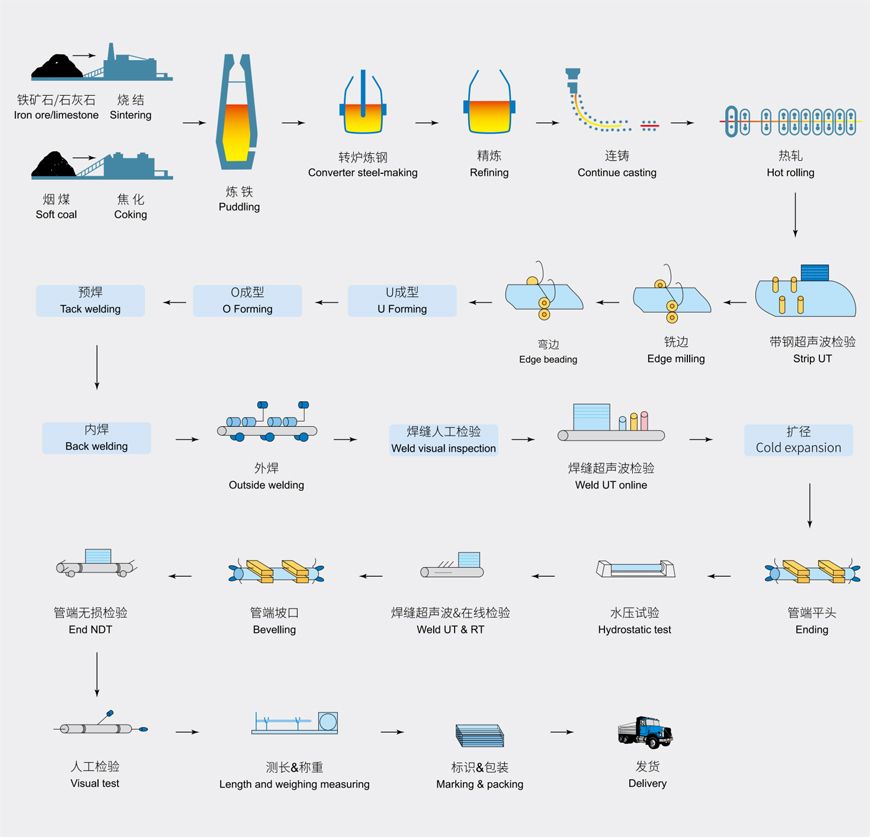

Mokhoa oa Tlhahiso

Taolo ea Boleng

● Ho hlahloba thepa e tala

● Tlhahlobo ea Lik'hemik'hale

● Teko ea Mekaniki

● Tlhahlobo ea Pono

● Tlhahlobo ea Tekanyo

● Teko ea ho Kobeha

● Teko ea Tšusumetso

● Teko ea ho Sila ha li-intergranular

● Tlhahlobo e sa Senyeheng (UT, MT, PT)

● Tšoaneleho ea Tsamaiso ea ho Chesa

● Tlhahlobo ea Sebopeho se Senyenyane

● Teko ea ho Chesa le ho Fokotsa

● Teko ea ho tiea

● Teko ea Hydrostatic

● Teko ea Metalography

● Teko ea ho Petsoha e Bakiloeng ke Haeterojene (HIC)

● Teko ea ho Petsoha ha Khatello ea Sulfide (SSC)

● Teko ea Hona Joale ea Eddy

● Tlhahlobo ea ho Penta le ho Koahela

● Tlhahlobo ea Litokomane

Tšebeliso le Tšebeliso

Liphaephe tsa tšepe tsa LSAW (Longitudinal Submerged Arc Welding) li fumana lits'ebetso tse fapaneng liindastering tse fapaneng ka lebaka la botšepehi ba tsona ba sebopeho le ho tenyetseha. Ka tlase ke tse ling tsa ts'ebeliso ea bohlokoa le ts'ebeliso ea liphaephe tsa tšepe tsa LSAW:

● Lipalangoang tsa Oli le Khase: Liphaephe tsa tšepe tsa LSAW li sebelisoa haholo indastering ea oli le khase bakeng sa litsamaiso tsa liphaephe. Liphaephe tsena li sebelisoa bakeng sa ho tsamaisa oli e tala, khase ea tlhaho le maro a mang kapa likhase.

● Meralo ea Motheo ea Metsi: Liphaephe tsa LSAW li sebelisoa mererong ea meralo ea motheo e amanang le metsi, ho kenyeletsoa phepelo ea metsi le litsamaiso tsa drainage.

● Ts'ebetso ea Lik'hemik'hale: Liphaephe tsa LSAW li sebeletsa liindastering tsa lik'hemik'hale moo li sebelisetsoang ho tsamaisa lik'hemik'hale, metsi le likhase ka mokhoa o sireletsehileng le o sebetsang hantle.

● Kaho le Meralo ea Motheo: Liphaephe tsena li sebelisoa mererong e fapaneng ea kaho, joalo ka metheo ea kaho, marokho le lits'ebetso tse ling tsa kaho.

● Ho kenya lipeipi: Lipeipi tsa LSAW li sebelisoa lits'ebetsong tsa ho kenya lipeipi ho fana ka tšehetso ea motheo mererong ea kaho, ho kenyeletsoa metheo ea kaho le meaho ea leoatle.

● Lekala la Matla: Li sebelisetsoa ho tsamaisa mefuta e fapaneng ea matla, ho kenyeletsoa mouoane le maro a mocheso lifemeng tsa tlhahiso ea motlakase.

● Merafo: Liphaephe tsa LSAW li sebelisoa mererong ea merafo bakeng sa ho tsamaisa thepa le li-tailings.

● Mekhoa ea Liindasteri: Liindasteri tse kang tlhahiso le tlhahiso li sebelisa liphaephe tsa LSAW bakeng sa mekhoa e fapaneng ea indasteri, ho kenyeletsoa le ho tsamaisa thepa e tala le lihlahisoa tse felileng.

● Ntlafatso ea Meralo ea Motheo: Liphaephe tsena lia hlokahala ho nts'etsapele merero ea meralo ea motheo e kang litsela, litsela tse kholo le lits'ebeletso tsa ka tlas'a lefatše.

● Tšehetso ea Meaho: Liphaephe tsa LSAW li sebelisetsoa ho etsa litšehetso tsa meaho, likholomo le maballo mererong ea kaho le ea boenjiniere.

● Kaho ea likepe: Indastering ea kaho ea likepe, liphaephe tsa LSAW li sebelisoa bakeng sa ho haha likarolo tse fapaneng tsa likepe, ho kenyeletsoa le li-hull le likarolo tsa sebopeho.

● Indasteri ea Likoloi: Liphaephe tsa LSAW li ka sebelisoa tlhahisong ea likarolo tsa likoloi, ho kenyeletsoa le litsamaiso tsa mosi.

Lisebelisoa tsena li bontša ho tenyetseha ha liphaephe tsa tšepe tsa LSAW ho pholletsa le makala a fapaneng, ka lebaka la ho tšoarella ha tsona, matla le ho tšoaneleha bakeng sa maemo a fapaneng a tikoloho.

Ho paka le ho Romela

Ho paka le ho romela ka nepo liphaephe tsa tšepe tsa LSAW (Longitudinal Submerged Arc Welding) ho bohlokoa ho netefatsa hore li tsamaisoa ka mokhoa o sireletsehileng le ho isoa libakeng tse fapaneng. Tlhaloso ea mekhoa e tloaelehileng ea ho paka le ho romella liphaephe tsa tšepe tsa LSAW ke ena:

Pakete:

● Ho kopanya: Liphaephe tsa LSAW hangata li kopanngoa hammoho kapa li pakoa ka karolo e le 'ngoe ho sebelisoa marapo a tšepe kapa likhoele ho etsa li-unit tse laolehang bakeng sa ho sebetsana le ho tsamaisa.

● Tšireletso: Lipheletso tsa liphaephe li sirelelitsoe ka likhurumetso tsa polasetiki ho thibela tšenyo nakong ea ho tsamaea. Ho feta moo, liphaephe li ka koaheloa ka thepa e sireletsang ho itšireletsa khahlanong le mabaka a tikoloho.

● Sekoahelo se Thibelang ho Senyeha: Haeba liphaephe li na le sekoahelo se thibelang ho senyeha, botšepehi ba sekoahelo boa netefatsoa nakong ea ho paka ho thibela tšenyo nakong ea ho sebetsana le ho tsamaisoa.

● Ho Tšoaea le ho Ngola: Sephutheloana se seng le se seng se ngoloa ka tlhahisoleseding ea bohlokoa joalo ka boholo ba phaephe, kereiti ea thepa, nomoro ea mocheso, le litlhaloso tse ling bakeng sa ho khetholla habonolo.

● Ho tiisa: Liphutheloana li tlameletsoe ka thata ho liphaleteng kapa li-skid ho thibela ho sisinyeha nakong ea lipalangoang.

Ho tsamaisa ka sekepe:

● Mekhoa ea Lipalangoang: Liphaephe tsa tšepe tsa LSAW li ka romelloa ka mekhoa e fapaneng ea lipalangoang, ho kenyeletsoa le litsela, literene, leoatle, kapa moea, ho latela moo li eang teng le ho potlaka ha tsona.

● Ho kenya lijana ka har'a lijana: Liphaephe li ka romelloa ka har'a lijana bakeng sa tšireletso e eketsehileng, haholo-holo nakong ea lipalangoang tsa mose ho maoatle. Lijana lia kenngoa 'me lia tiisoa ho thibela ho falla nakong ea lipalangoang.

● Balekane ba Logistics: Lik'hamphani tse hlomphehang tsa logistics kapa bajari ba nang le boiphihlelo ba ho sebetsana le liphaephe tsa tšepe ba kopanngoa ho netefatsa hore thepa e tla tlisoa ka mokhoa o sireletsehileng le ka nako.

● Litokomane tsa Lekgetho: Litokomane tse hlokahalang tsa lekgetho, ho kenyeletsoa le dipampiri tsa thepa, disetifikeiti tsa tshimoloho, le dipampiri tse ding tse amehang, di a lokiswa mme di romelwa bakeng sa thomello ya matjhaba.

● Inshorense: Ho latela boleng le mofuta oa thepa, inshorense e ka hlophisoa ho itšireletsa khahlanong le liketsahalo tse sa lebelloang nakong ea lipalangoang.

● Ho Latela: Mekhoa ea sejoale-joale ea ho Latela e lumella moromelli le moamoheli ho latela tsoelo-pele ea thomello ka nako ea sebele, e leng se netefatsang pepeneneng le lintlafatso tse nakong.

● Thomello: Liphaephe li laolloa moo li eang teng, ho latela mekhoa e nepahetseng ea ho laolla thepa ho qoba tšenyo.

● Tlhahlobo: Ha liphaephe li fihla, li ka hlahlojoa ho netefatsa boemo ba tsona le ho latela litlhaloso pele li amoheloa ke moamoheli.

Mekhoa e nepahetseng ea ho paka le ho romela thepa e thusa ho thibela tšenyo, ho boloka botšepehi ba liphaephe tsa tšepe tsa LSAW, le ho netefatsa hore li fihla libakeng tseo li reretsoeng ho li isa ho tsona ka mokhoa o sireletsehileng le o boemong bo botle.