Kakaretso ea Sehlahisoa

Womic Steel e ikhethile tlhahisong ea boleng bo holimoDIN 2445-li-tube tsa tšepe tse se nang sekoli tse netefalitsoeng, tse entsoeng ka nepo le ho tšoarella. Li-tube tsa rona li loketse lits'ebetso tse fapaneng tse hlokang boiteko, ho kenyeletsoa litsamaiso tsa lipalangoang tsa metsi, likarolo tsa hydraulic, litsamaiso tsa likoloi le boenjiniere ba mechini. Ka theknoloji e tsoetseng pele ea tlhahiso le lits'ebetso tse tiileng tsa taolo ea boleng, re netefatsa hore lihlahisoa tsa rona li fihlela maemo a machaba, li fana ka ts'epo e ikhethang le ts'ebetso maemong ohle a ts'ebeliso.

Ea ronaLiphaephe tsa tšepe tse se nang mohele tsa DIN 2445li loketse lits'ebetso tse hlokang liphaephe tse matla haholo, tse entsoeng ka nepo tse fanang ka ts'ebetso e phahameng maemong a sa fetoheng le a fetohang. Liphaephe tsena li sebelisoa haholo lits'ebetsong tsa lipalangoang tsa metsi, lisilindara tsa hydraulic, mechini, lits'ebetsong tsa likoloi le lisebelisoa tsa indasteri.

Mefuta ea Tlhahiso ea Li-Tube tsa Tšepe tse se nang Seamless DIN 2445

- Bophara ba Kantle (OD): 6 mm ho isa ho 400 mm

- Botenya ba Lebota (WT): 1 mm ho isa ho 20 mm

- Bolelele: Bolelele bo ikgethileng bo fumaneha, hangata bo tloha ho limithara tse 6 ho isa ho tse 12, ho latela ditlhoko tsa projeke.

Mamello ea Li-Tube tsa Tšepe tse se nang Seam DIN 2445

Tšepe ea Womic e tiisa ho nepahala ho nepahetseng ha litekanyo, ka mamello e latelang e sebelisoang ho ronaLiphaephe tsa tšepe tse se nang mohele tsa DIN 2445:

| Paramethara | Mamello |

| Bophara ba Kantle (OD) | ± 0.01 mm |

| Botenya ba Lebota (WT) | ± 0.1 mm |

| Ho Oval (Ho Oval) | 0.1 mm |

| Bolelele | ± 5 mm |

| Ho otloloha | Boholo 1 mm ka mithara |

| Qetello ea Bokaholimo | Ho ya ka tlhaloso ya moreki (hangata: Oli e lwantshang mafome, Ho betla ka thata ha Chrome, Ho betla ka chromium ya nikeli, kapa ho betla ka tse ding) |

| Bolelele ba Lipheletso | ± 1° |

Di-tubes tsa Tšepe tse se nang Seamless tsa DIN 2445 Sebopeho sa Lik'hemik'hale

TheDIN 2445Lipeipi li etsoa ka likereiti tsa tšepe tsa boleng bo holimo. Kakaretso ea likereiti tse tloaelehileng tsa thepa le metsoako ea tsona ea lik'hemik'hale ke ena:

| E tloaelehileng | Sehlopha | Sebopeho sa Lik'hemik'hale (%) |

| DIN 2445 | St 37.4 | C: ≤0.17,Si: ≤0.35,Mn: 0.60-0.90,P: ≤0.025,S: ≤0.025 |

| DIN 2445 | St 44.4 | C: ≤0.20,Si: ≤0.35,Mn: 0.60-0.90,P: ≤0.025,S: ≤0.025 |

| DIN 2445 | St 52.4 | C: ≤0.22,Si: ≤0.55,Mn: 1.30-1.60,P: ≤0.025,S: ≤0.025 |

Likarolo tsa ho kopanya li ka eketsoa joalo kaNi≤ 0.3%,Cr≤ 0.3%, leMo≤ 0.1% ho latela ditlhoko tse itseng tsa kopo.

Maemo a ho Romela Di-tubes tsa Tšepe tse se Nang Seamless DIN 2445

Liphaephe li etsoa ka ho sebelisaho huloa ka seramekapaho phuthoa ka seramelits'ebetso 'me li fanoa ka

maemo a latelang a ho pepa:

| Tlhophiso | Letšoao | Tlhaloso |

| E felile ka serame (e thata) | BK | Liphaephe tse sa keneng kalafong ea mocheso ka mor'a ho thehoa ha serame sa ho qetela. Ho hanyetsa ho hoholo ho fetoha ha tsona. |

| E Felitsoe ka Batang (e Bonolo) | BKW | Ho hula ka serame ho lateloa ke kalafo ea mocheso e nang le phetoho e fokolang bakeng sa ho tenyetseha ha ho sebetsoa ho eketsehileng. |

| E felile ka serame le ho imolloa ke khatello ea maikutlo | BKS | Kalafo ea mocheso e sebelisoa ho imolla khatello ea maikutlo kamora ho thehoa ha serame sa ho qetela, e leng se nolofalletsang ts'ebetso e eketsehileng le ho sebetsa. |

| Annealed | GBK | Mokhoa oa ho qetela oa ho etsa serame o lateloa ke ho annealing sepakapakeng se laoloang ho ntlafatsa ho ductility le ho nolofatsa ts'ebetso e tsoelang pele. |

| E tloaelehileng | NBK | Ho thehoa ha serame ho lateloa ke ho kenngoa ha metsi ka holim'a ntlha e ka holimo ea phetoho ho ntlafatsa litšobotsi tsa mechini. |

Li-tubes tsa Tšepe tse se nang Seamless DIN 2445 Thepa ea Mechanical

Thepa ea mechini bakeng saDIN 2445Lipeipi tsa tšepe, tse lekanngoang mochesong oa kamore, li fapana ho latela sehlopha sa tšepe le boemo ba ho tlisoa:

| Kereiti ea Tšepe | Boleng bo tlase bakeng sa boemo ba ho pepa |

| St 37.4 | Rm: 360-510 MPa,A%: 26-30 |

| St 44.4 | Rm: 430-580 MPa,A%: 24-30 |

| St 52.4 | Rm: 500-650 MPa,A%: 22-30 |

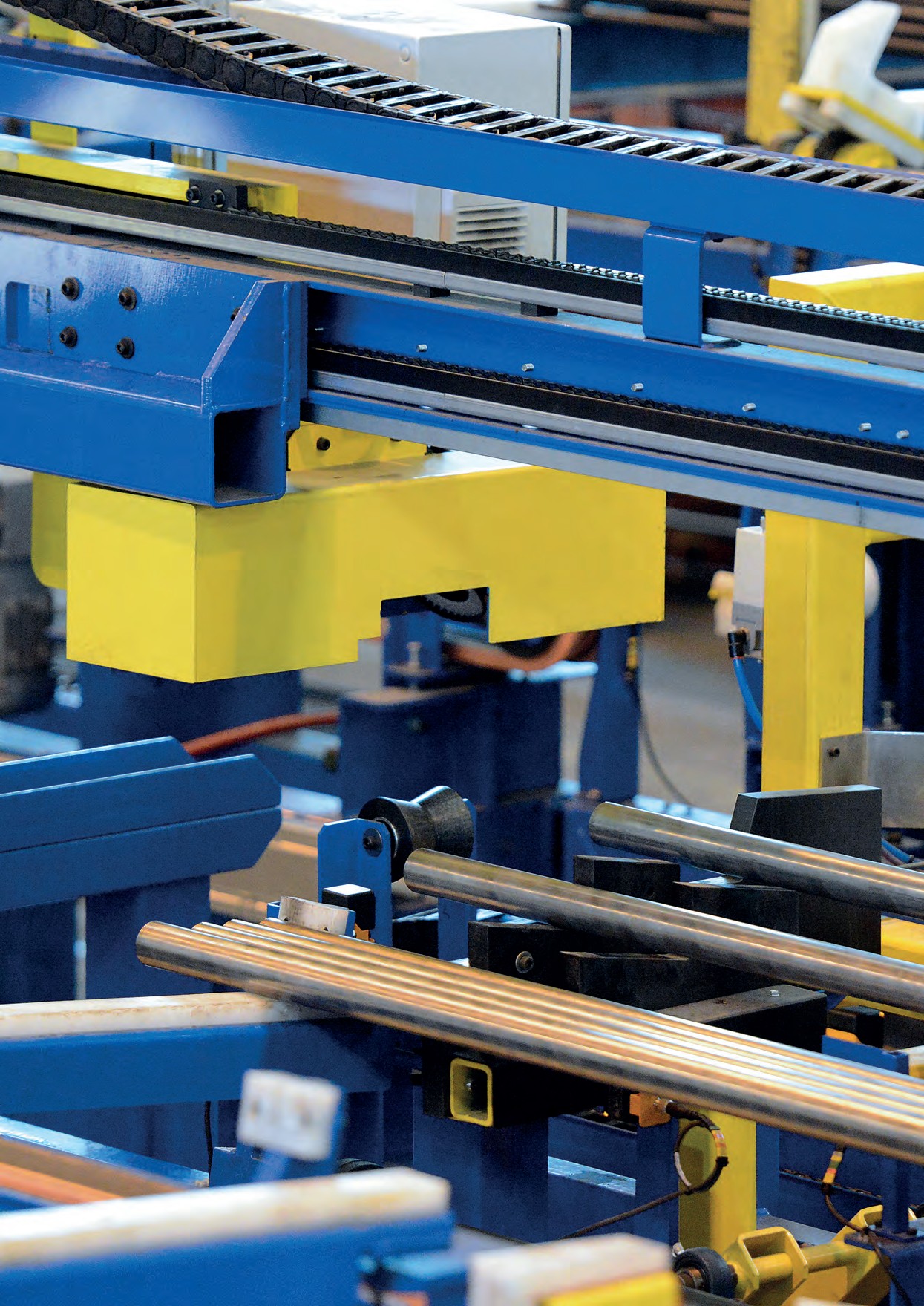

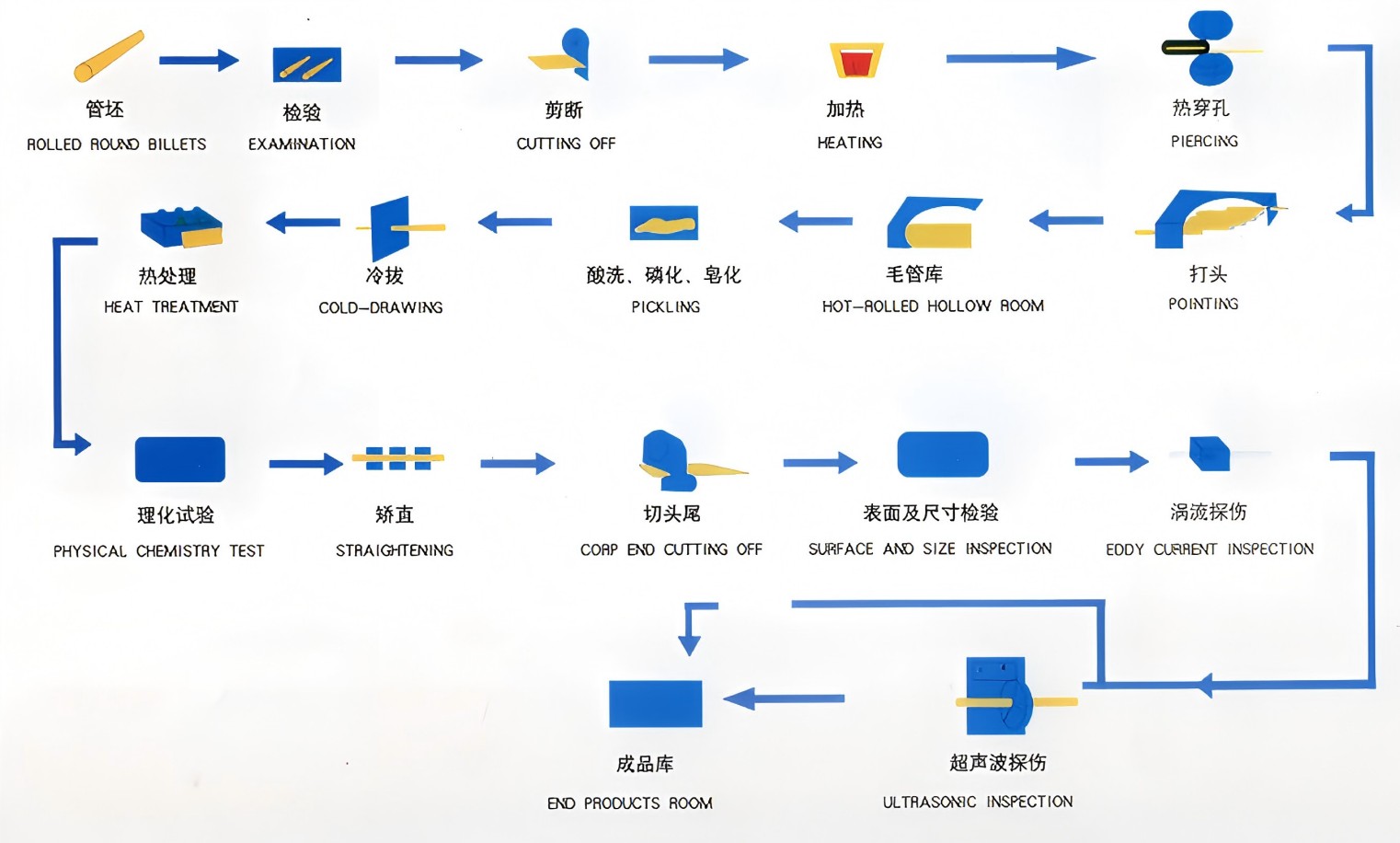

Mokhoa oa ho Etsa Li-Tube tsa Tšepe tse se Nang Seamless DIN 2445

Womic Steel e sebelisa theknoloji e tsoetseng pele ea tlhahiso ho hlahisaLiphaephe tsa tšepe tse se nang mohele tsa DIN 2445, ho netefatsa ho nepahala ho hoholo le ho tšoarella. Ts'ebetso ea rona ea tlhahiso e kenyelletsa:

- Khetho ea Billet le Tlhahlobo: Tlhahiso e qala ka di-billet tsa tshepe tsa boleng bo hodimo, tse hlahlojwang bakeng sa botsitso le boleng pele di sebetswa.

- Ho futhumatsa le ho phunya: Li-billet lia futhumatsoa le ho phunngoa ho etsa phaephe e se nang letho, e leng se behang motheo oa ho bopa hape.

- Ho Roller e Chesang: Li-billet tse phunyeletsoeng li phuthoa ka mocheso ho fihlela litekanyo tse lakatsehang.

- Setšoantšo se batang: Liphaephe tse phutholotsoeng ka mocheso li huloa ka serame ho fihlela bophara bo nepahetseng le botenya ba mabota.

- Ho seha: Liphaephe lia qhibilihisoa ho tlosa litšila, ho netefatsa hore bokaholimo bo hloekile.

- Kalafo ea Mocheso: Liphaephe li feta lits'ebetsong tsa kalafo ea mocheso tse kang ho annealing ho ntlafatsa litšobotsi tsa mechini.

- Ho otlolla le ho Seha: Liphaephe li otlolohile 'me li sehoa ka bolelele bo ikhethileng ho latela litlhaloso tsa moreki.

- Tlhahlobo le Teko: Litlhahlobo tse felletseng, ho kenyeletsoa le liteko tsa boholo, liteko tsa mechini, le liteko tse sa senyeheng joalo ka liteko tsa eddy current le ultrasound, lia etsoa ho netefatsa boleng ba sehlahisoa.

Teko le Tlhahlobo

Womic Steel e netefatsa ho sala morao ka botlalo le netefatso ea boleng bakeng sa bohleLiphaephe tsa tšepe tse se nang mohele tsa DIN 2445ka liteko tse latelang:

- Tlhahlobo ea litekanyo: Tekanyo ea OD, WT, bolelele, ovality, le ho otloloha.

- Teko ea Mechini: Teko ea ho tsitlella, teko ea tšusumetso, le teko ea ho thatafala.

- Teko e sa Senyeheng (NDT): Teko ea hona joale ea Eddy bakeng sa liphoso tsa ka hare, teko ea ultrasound (UT) bakeng sa botenya le botšepehi ba lebota.

- Tlhahlobo ea Lik'hemik'hale: Sebopeho sa thepa se netefalitsoe ka mekhoa ea spectrographic.

- Teko ea Hydrostatic: E leka bokgoni ba phaephe ba ho mamella kgatello ya kahare ntle le ho hloleha.

Taolo ea Laboratori le Boleng

Womic Steel e sebetsa laboratori e nang le lisebelisoa tse felletseng tsa liteko le tlhahlobo tse tsoetseng pele. Litsebi tsa rona tsa tekheniki li etsa liteko tsa boleng ba kahare ho sehlopha se seng le se seng sa lipeipi, ho netefatsa hore li latela melao.DIN 2445Mekhatlo ea mokha oa boraro le eona e etsa netefatso ea kantle bakeng sa netefatso e eketsehileng ea boleng.

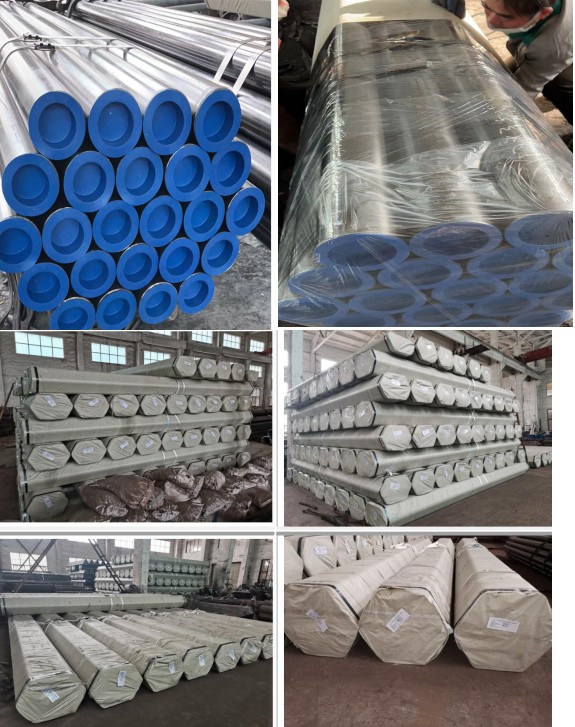

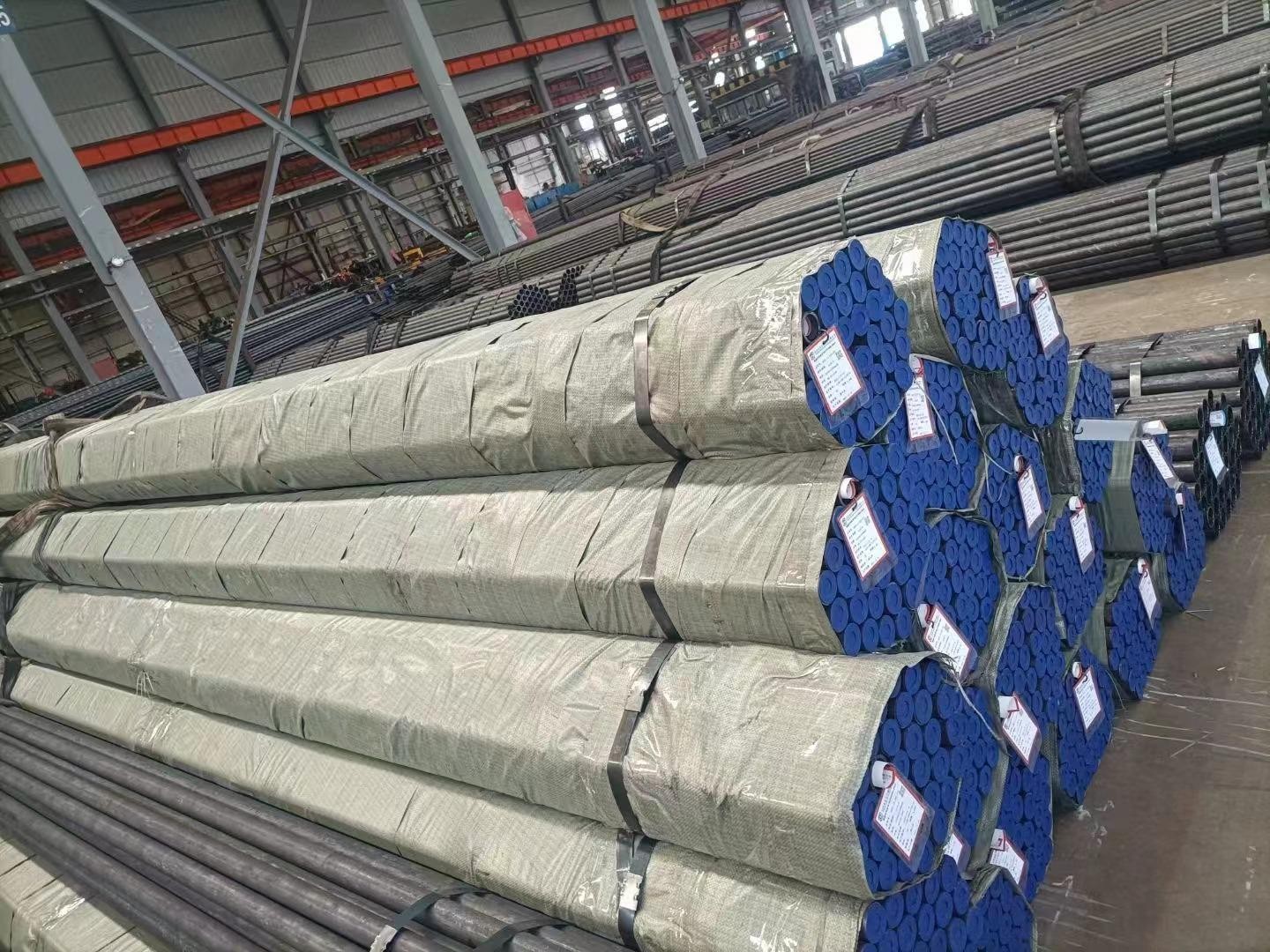

Sephutheloana

Ho netefatsa hore lipalangoang tsa rona li bolokehileLiphaephe tsa tšepe tse se nang mohele tsa DIN 2445, Womic Steel e latela maemo a holimo ka ho fetisisa a ho paka:

- Sekoahelo se Sireletsang: Sekoahelo se thibelang ho bola ho thibela mafome le oxidation.

- Li-cap tsa ho qetela: Ho kwala mahlakore ka bobedi a diphaephe ka dikoahelo tsa polasetiki kapa tsa tshepe ho thibela tshilafatso.

- Ho kopanya: Liphaephe li tlameletsoe ka thata ka marapo a tšepe, mabanta a polasetiki, kapa marapo a lohiloeng.

- Ho phuthela ka bonolo: Liphutheloana li phuthetsoe ka filimi e nyenyefatsang ho li sireletsa khahlanong le mabaka a tikoloho.

- Ho ngola mabitso: Sephutheloana se seng le se seng se ngotsoe ka ho hlaka ka lintlha tsa bohlokoa tsa sehlahisoa, ho kenyeletsoa le boleng ba tšepe, litekanyo le bongata.

Lipalangoang

Womic Steel e netefatsa hore ho fanoa ka nako e nepahetseng le ka polokeho lefatšeng ka bopharaLiphaephe tsa tšepe tse se nang mohele tsa DIN 2445:

- Thepa ea Leoatleng: Bakeng sa thomello ea machabeng, liphaephe li kenngoa ka har'a lijana kapa li-rack tse bataletseng 'me li romeloa lefatšeng ka bophara.

- Lipalangoang tsa Terene kapa tsa Tsela: Thomello ea thepa malapeng le libakeng tse ling e etsoa ka terene kapa teraka, ka mekhoa e nepahetseng ea ho tiisa ho thibela ho falla.

- Taolo ea Tlelaemete: Re ka fana ka lipalangoang tse laoloang ke boemo ba leholimo ha ho hlokahala, haholo-holo bakeng sa thepa e bonolo.

- Litokomane le Inshorense: Litokomane tse felletseng tsa ho romela thepa le inshorense lia fanoa ho netefatsa hore thepa e romelloa ka mokhoa o sireletsehileng le o tšepahalang.

- Tlhahiso e Nepahetseng: Ho nepahala ho hoholo ka mamello ea litekanyo le thepa ea mechini.

- Ho iketsetsa: Litharollo tse tenyetsehang bakeng sa bolelele, kalafo ea bokaholimo le sephutheloana.

- Teko e Felletseng: Teko e matla e netefatsa hore sehlahisoa se seng le se seng se fihlela maemo a indasteri.

- Phano ea Lefatše ka Bophara: Thomello e tšepahalang le e nakong lefatšeng ka bophara.

- Sehlopha se nang le boiphihlelo: Baenjiniere ba nang le tsebo e phahameng ba netefatsang maemo a holimo a tlhahiso le tšebeletso ea bareki.

Melemo ea ho Khetha Tšepe ea Basali

Qetello

Tšepe ea WomicLiphaephe tsa Tšepe tse se nang Seamless tsa DIN 2445fana ka matla a phahameng, botšepehi le ho nepahala bakeng sa lits'ebetso tse fapaneng tse hlokang boiteko. Boitlamo ba rona ho boleng, liteko tse thata, le litharollo tse tenyetsehang tsa bareki li re etsa molekane ea tšepahalang bakeng sa tlhahiso ea lipeipi tse se nang sekoli.

Khetha Womic Steel bakeng saLiphaephe tsa Tšepe tse se nang Seamless tsa DIN 2445le ho ba le boiphihlelo ba boleng bo holimo le tšebeletso ea bareki.

Bakeng sa lintlha tse ling, ka kopo ikopanye le rona ka kotloloho:

Webosaete: www.womicsteel.com

Imeile: sales@womicsteel.com

Mohala/WhatsApp/WeChat: Victor: +86-15575100681 kapa Jack: +86-18390957568