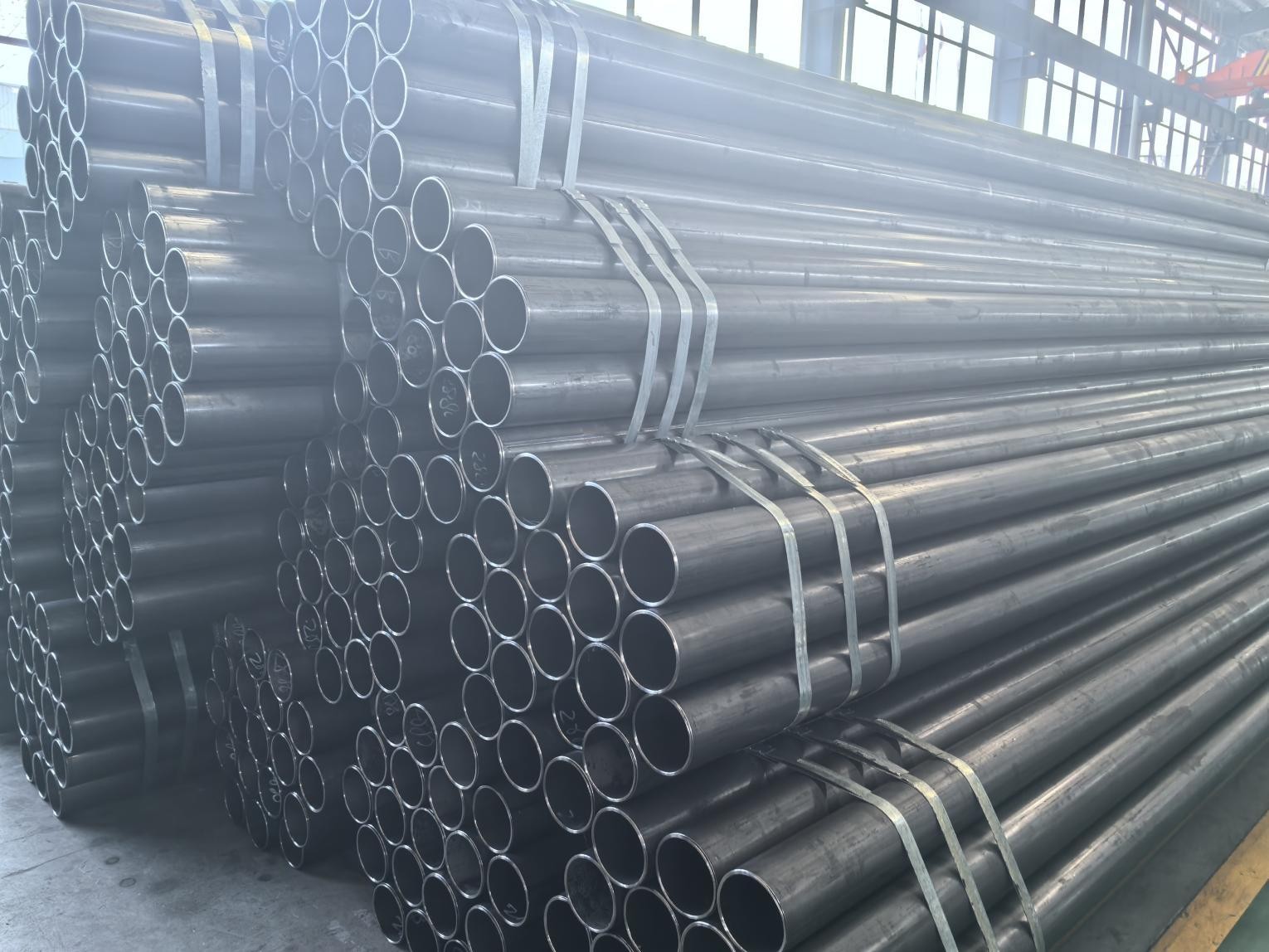

Womic Steel e ikhethile ka ho hlahisa liphaephe tsa tšepe tsa boleng bo holimo tse lumellanang leDIN 2391maemo. Liphaephe tsa rona li etselitsoe mefuta e fapaneng ea lits'ebetso, ho kenyeletsoa le litsamaiso tsa lipalangoang tsa meaho, tsa mechini le tsa metsi. Re sebelisa theknoloji e tsoetseng pele ea tlhahiso le lits'ebetso tse thata tsa taolo ea boleng, re netefatsa hore lihlahisoa tsa rona li fihlela maemo a machaba, li fana ka ho tšoarella ho sa bapisoeng, ho nepahala le ts'ebetso.

Liphaephe tsa rona tsa tšepe li loketse haholo ho sebelisoa ho li-idlers, li-cylinder tsa hydraulic le tsa pneumatic, boenjiniere ba mechini le likoloi, mechini, li-cylinder tsa oli, li-cylinder tsa tšepe tsa lithuthuthu tse monyang motlakase, le li-cylinder tsa ka hare tsa li-injini tse monyang motlakase tse iketsang motlakase. Ts'ebeliso ena e hloka liphaephe tse matla haholo, tse entsoeng ka nepo tse fanang ka ts'epo e ntle le ts'ebetso libakeng tse hlokang matla.

DIN 2391 Liphaephe tse se nang seamless Precision Mefuta ea Tlhahiso:

- Bophara ba Kantle (OD): 6 mm ho isa ho 400 mm

- Botenya ba Lebota (WT): 1 mm ho isa ho 18 mm

- Bolelele: Bolelele bo ikgethileng bo fumaneha, hangata bo tloha ho limithara tse 6 ho isa ho tse 12, ho latela ditlhoko tsa projeke.

DIN 2391 Liphaephe tse se nang seamless Precision Mamello:

| Paramethara | Mamello |

| Bophara ba Kantle (OD) | ± 0.01mm |

| Botenya ba Lebota (WT) | ± 0.1 mm ea botenya ba lebota bo boletsoeng |

| Ho Oval (Ho Oval) | 0.1 mm |

| Bolelele | ± 5 mm |

| Ho otloloha | Boholo 1 mm ka mithara |

| Qetello ea Bokaholimo | Ho ya ka tlhaloso ya moreki (Hangata: Oli e lwantshang mafome, Ho betla ka chrome e thata, ho betla ka chromium ya nickel, kapa ho betla ho hong) |

| Bolelele ba Lipheletso | ± 1° |

DIN 2391 Liphaephe tse se nang seamless Precision Sebopeho sa Lik'hemik'hale

| E tloaelehileng | Sehlopha | Likarolo tsa Lik'hemik'hale (%) | |||||

| Letšoao | Nomoro ea thepa | C | Si | Mn | P | S | |

| DIN2391 | St 30 Si | 1.0211 | ≤0.10 | ≤0.30 | ≤0.55 | ≤0.025 | ≤0.025 |

| St 30 Al | 1.0212 | ≤0.10 | ≤0.05 | ≤0.55 | ≤0.025 | ≤0.025 | |

| St 35 | 1.0308 | ≤0.17 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| St 5 | 1.0408 | ≤0.21 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| St 52 | 1.058 | ≤0.22 | ≤0.55 | ≤1.60 | ≤0.025 | ≤0.025 | |

Dikarolo tse latelang tsa ho kopanya di ka eketswa: Nb: ≤ 0,03 %; Ti: ≤ 0,03 %; V: ≤ 0,05 %; Nb + Ti + V: ≤ 0,05 %

DIN 2391 Liphaephe tse se nang seamless Precision Maemo a Phano

Liphaephe tsena li lokela ho etsoa ka mekhoa e huloang ka mokhoa o batang kapa o batang. Liphaephe tsena li tla fanoa tlas'a e 'ngoe ea maemo a ho tlisoa ka tsela e latelang:

| Tlhophiso | Letšoao | Tlhaloso |

| E qetile ka serame (e thata) | BK | Lipeipi ha li futhumatsoe ka mocheso ka mor'a ho thehoa ha serame sa ho qetela, kahoo li na le khanyetso e phahameng haholo khahlanong le ho fetoha ha tsona. |

| E batang e felile (e bonolo) | BKW | Kalafo ea ho qetela ea mocheso e lateloa ke ho hula ho batang ho kenyeletsang ho fetoha ho fokolang. Ts'ebetso e nepahetseng e tsoelang pele e lumella tekanyo e itseng ea ho thehoa ha serame (mohlala, ho kobeha, ho atoloha). |

| E felile ka serame 'me e imolloa ke khatello ea maikutlo | BKS | Kalafo ea mocheso e sebelisoa kamora ts'ebetso ea ho qetela ea ho theha serame. Ho latela maemo a loketseng a ts'ebetso, keketseho ea likhatello tse setseng tse amehang e nolofalletsa ho theha le ho sebetsa ka mokhoa o itseng. |

| Annealed | GBK | Mokhoa oa ho qetela oa ho theha serame o lateloa ke ho annealing sepakapakeng se laoloang. |

| E tloaelehileng | NBK | Mokhoa oa ho qetela oa ho theha serame o lateloa ke ho kenngoa ha metsi ka holim'a ntlha e ka holimo ea phetoho sepakapakeng se laoloang. |

DIN 2391 Liphaephe tse se nang seamless Precision Matlotlo a Mekaniki.

| Thepa ea mechini mochesong oa kamore | |||||||||||||

| Kereiti ea Tšepe | Boleng bo tlase bakeng sa boemo ba ho pepa | ||||||||||||

| Lebitso la Tšepe | Nomoro ea Tšepe | BK | BKW | BKS | GBK | NBK | |||||||

| Rm | % | Rm | % | Rm | ReH | % | Rm | % | Rm | ReH | % | ||

| Mpa | Mpa | Mpa | Mpa | Mpa | Mpa | Mpa | |||||||

| St 30 Si | 1.0211 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 ho isa ho 420 | 215 | 30 |

| St 30 Al | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 ho isa ho 420 | 215 | 30 |

| St 35 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 315 | 14 | 315 | 25 | 340 ho isa ho 470 | 235 | 25 |

| St 45 | 1.0408 | 580 | 5 | 520 | 8 | 520 | 375 | 12 | 390 | 21 | 440 ho isa ho 570 | 255 | 21 |

| St 52 | 1.0580 | 640 | 4 | 580 | 7 | 580 | 420 | 10 | 490 | 22 | 490 ho isa ho 630 | 355 | 22 |

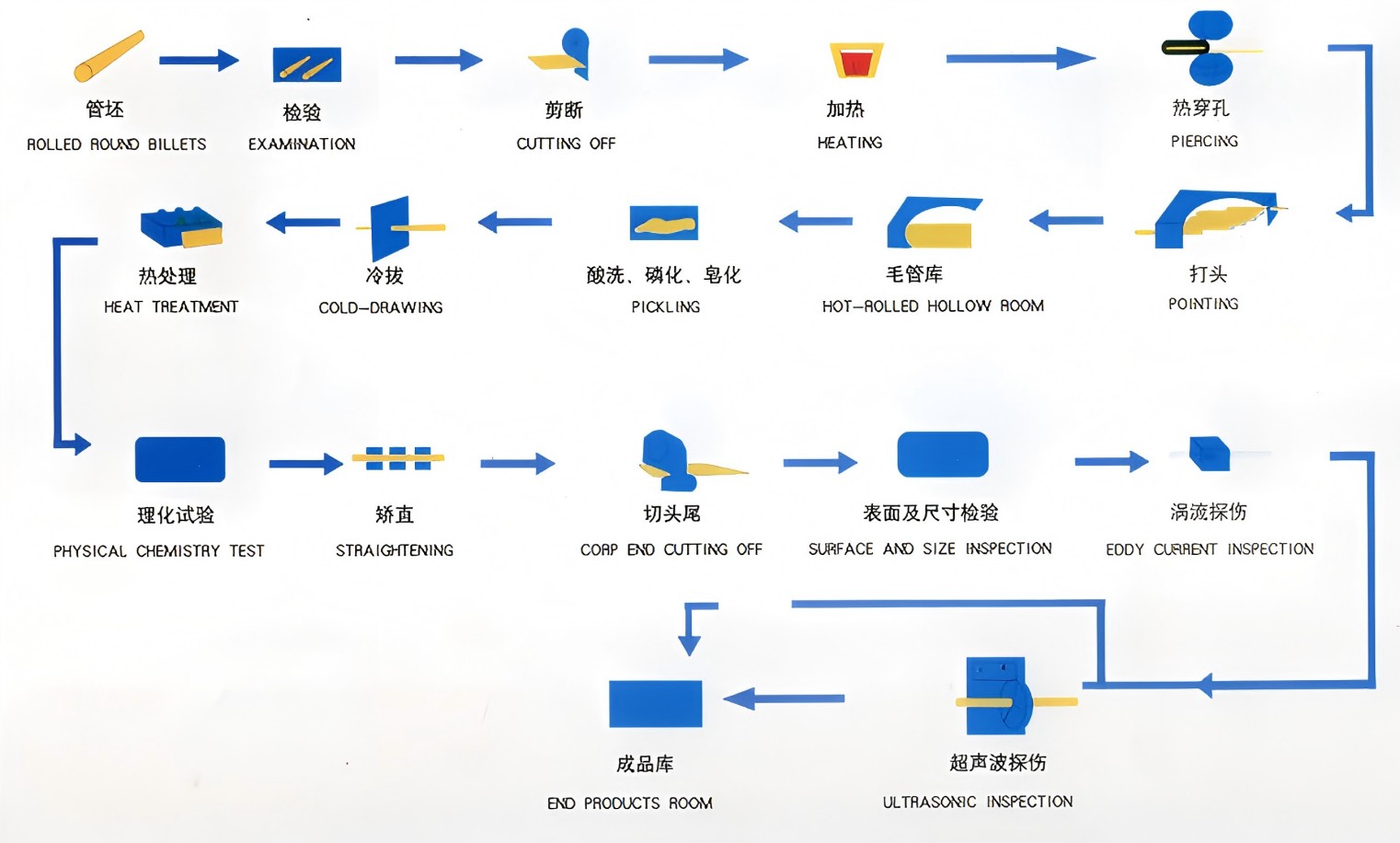

DIN 2391 Liphaephe tse se nang seamless Precision Mokhoa oa Tlhahiso:

- ·Li-billet tse chitja tse phutholohileng: Tlhahiso e qala ka ho sebelisa li-billet tse chitja tse phutholohileng, e leng thepa ea pele e tala ka mokhoa oa lithupa tsa tšepe.

- ·Tlhahlobo: Li-billet tsena li hlahlojoa pele bakeng sa boleng le botsitso ho netefatsa hore li fihlela maemo a hlokahalang pele li tsoela pele mohatong o latelang.

- ·Ho Khaola: Li-billet li sehoa ka bolelele bo lakatsehang ho lekana litlhoko tsa ts'ebetso e tsoelang pele.

- ·Ho futhumatsa: Li-billet tse khaotsoeng li futhumatsoa mochesong o phahameng ho li etsa hore li lokele ho fetoloa ho ea pele mehatong e latelang.

- ·Ho phunya: Li-billet tse futhumetseng lia phunngoa ho etsa setsi se se nang letho, se etsang sebopeho sa motheo sa phaephe e se nang sekoli.

- ·Kamore e Meholo e Meholo: Li-billet tse se nang letho li fetoloa ho tjhesa ho bopa phaephe haholoanyane.

- ·E huloa ke serame: Liphaephe tse phutholotsoeng ka mocheso li huloa ka har'a die tlas'a maemo a laoloang, ho fokotsa bophara le botenya, le ho ntlafatsa boholo ba phaephe.

- ·Ho seha: Liphaephe li tšeloa ka har'a tharollo ea asiti ho tlosa sekala sefe kapa sefe sa bokaholimo kapa litšila tse bopiloeng nakong ea ts'ebetso ea tlhahiso.

- ·Kalafo ea Mocheso: Liphaephe li phekoloa ka mocheso, e leng se kenyeletsang lits'ebetso tse kang ho annealing ho ntlafatsa thepa ea tsona ea mechini le ho imolla khatello ea maikutlo.

- ·Teko ea Khemistri ea 'Mele: Liphaephe li etsoa liteko tsa 'mele le tsa lik'hemik'hale ho netefatsa hore li fihlela litlhoko le thepa e hlokahalang.

- ·Ho otlolla: Kamora kalafo ea mocheso, liphaephe lia otlolloa ho netefatsa hore lia tšoana ebile li nepahetse.

- ·Ho Khaola Qetello ea Khoele: Lipheletso tsa liphaephe li khaotsoe ho fihlela bolelele bo hlokahalang.

- ·Tlhahlobo ea Bokaholimo le Boholo: Liphaephe li hlahlojoa ka botlalo bakeng sa liphoso tsa bokaholimo 'me li hlahlojoa ho nepahala ha litekanyo ho netefatsa boleng.

- ·Tlhahlobo ea Hona Joale ea Eddy: Teko ena e sa senyeheng e sebelisetsoa ho lemoha mapetso afe kapa afe a bokaholimo kapa likoli tse ka 'nang tsa se bonahale ka mahlo a hlobotseng.

- ·Tlhahlobo ea Ultrasonic: Liphaephe li etsoa liteko tsa ultrasound ho fumana liphoso kapa mefokolo efe kapa efe ea ka hare e ka amang matla kapa botšepehi ba phaephe.

- ·Kamore ea Lihlahisoa tsa Qetello: Qetellong, liphaephe tse felileng li romeloa ka phapusing ea lihlahisoa tsa ho qetela, moo li pakelloang le ho lokisetsoa ho romelloa.

Teko le Tlhahlobo:

Tšepe ea Womic e tiisa ho sala morao ka botlalo le netefatso ea boleng bakeng sa li-tubes tsa allDIN 2391 tse se nang seamless Precision ka liteko tse latelang:

- Tlhahlobo ea litekanyo: Tekanyo ea OD, WT, bolelele, ovality, le ho otloloha.

- Teko ea Mechini:

- Teko ea ho Tenyetseha

- Teko ea Tšusumetso

- Teko ea ho tiea

- Teko e sa Senyeheng (NDT):Tlhahlobo ea Lik'hemik'hale: E tsamaisitsoe ho netefatsa sebopeho sa thepa ho sebelisoa mekhoa ea spectrographic.

- Teko ea Hona Joale ea Eddy bakeng sa liphoso tsa ka hare

- Teko ea Ultrasonic (UT) bakeng sa botenya le botšepehi ba lebota

- Teko ea Hydrostatic: Ho hlahloba bokgoni ba phaephe ba ho mamella kgatello ya kahare ntle le ho hloleha.

Taolo ea Laboratori le Boleng:

Womic Steel e sebetsa laboratori e nang le lisebelisoa tse felletseng tsa liteko le tlhahlobo ho netefatsa hore e latela maemo a DIN 2391 Seamless Precision Tubes. Litsebi tsa rona tsa tekheniki li etsa liteko tsa boleng ba ka hare khafetsa sehlopheng se seng le se seng sa liphaephe. Re boetse re sebetsa haufi-ufi le mekhatlo e ikemetseng ea mokha oa boraro bakeng sa netefatso ea kantle ea boleng ba liphaephe.

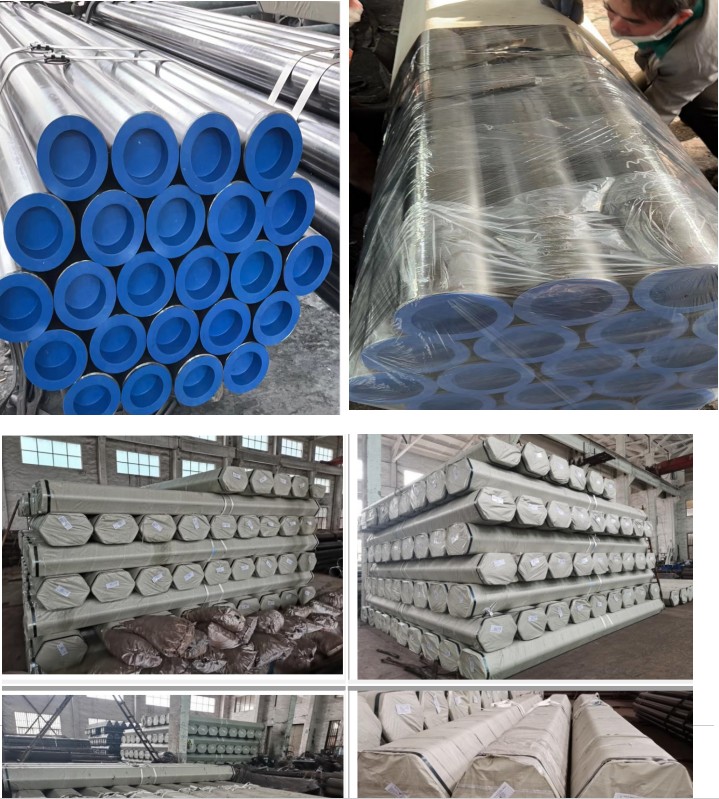

Sephutheloana

Sekoahelo se Sireletsang: Phaephe e 'ngoe le e 'ngoe e hloekisoa le ho koaheloa ka lera le thibelang ho bola ho thibela ho bola kapa ho rusa nakong ea ho tsamaisoa le ho bolokoa. Sena se ka kenyelletsa lera la oli, boka, kapa masela a mang a sireletsang ho latela litlhoko tsa bareki.

Li-cap tsa ho qetela: Lipheletso ka bobeli tsa lipeipi li koetsoe ka likheo tsa polasetiki kapa tsa tšepe ho thibela litšila, mongobo le tšenyo nakong ea ho sebetsana le ho tsamaisa.

Ho kopanya: Liphaephe li kopantsoe ka har'a liphutheloana tse laolehang, hangata ka bolelele bo lumellanang le litlhoko tse tloaelehileng tsa ho romela. Liphaephe li phutheloa ka lithapo tsa tšepe, lithapo tsa polasetiki, kapa lithapo tse lohiloeng ho li tšoara hammoho ka mokhoa o sireletsehileng.

Tšireletso pakeng tsa Liphaephe: Ho qoba ho kopana ka ho toba le ho thibela ho ngoapa kapa ho senya, lipeipi tse ka har'a liphutheloana hangata li aroloa ka thepa e sireletsang joalo ka khateboto, li-spacer tsa lehong, kapa li-insert tsa foam.

Lisebelisoa tsa ho paka: Lipakete tsa lipeipi hangata li phutheloa ka thin wrap kapa filimi ea polasetiki e boima ho netefatsa hore li lula li sa senyeha nakong ea lipalangoang 'me li sirelelitsoe lerōleng le mongobong.

Boitsebiso le ho Ngola: Sephutheloana se seng le se seng se tšoailoe ka ho hlaka ka lintlha tsa sehlahisoa, ho kenyeletsoa le sehlopha sa tšepe, litekanyo (bophara, botenya, bolelele), bongata, nomoro ea sehlopha, le litlhaloso tse ling tse amehang. Li-label li ka kenyelletsa litaelo tsa ho sebetsana le tsona tse kang "Boloka o Omme" kapa "Tšoara ka Hloko."

Lipalangoang

Mokhoa oa Lipalangoang:

Thepa ea Leoatleng: Bakeng sa thepa e romelloang linaheng tse ling, lipeipi tse nepahetseng tse se nang sekoli hangata li romelloa ka leoatle. Lipakete li kenngoa ka har'a lijana tsa thepa kapa holim'a li-rack tse bataletseng, ho latela boholo le bolelele ba lipeipi.

Lipalangoang tsa Terene kapa tsa Tsela: Bakeng sa thepa ea malapeng kapa ea libaka, liphaephe li ka tsamaisoa ka terene kapa tsela, tsa kenngoa literaka tse bataletseng kapa ka har'a lijana.

Ho kenya le ho Sireletsa: Ha di kentswe dikoloing tsa dipalangwang, diphuthelwana di tlangwa ka thata ho thibela ho sisinyeha kapa ho tsamaya nakong ya ho tsamaya. Sena se ka fihlellwa ka ho sebedisa marapo a tshepe, dithapo tsa polasetiki, le ditshehetso tse ding ka hara setshelo kapa teraka. Bakeng sa thepa ya lewatle, haeba diphaephe di se ka hara dikontenara, hangata di kentswe hodima diraka tse bataletseng mme di tiisetswa ka di-tarp kapa dikobo tse ding ho di sireletsa maemong a lehodimo a kang pula kapa ho pepesehela metsi a letswai.

Taolo ea Tlelaemete: Haeba ho hlokahala (haholo-holo libakeng tse mongobo kapa tse lebōpong la leoatle), maemo a laoloang a lipalangoang (mohlala, taolo ea mocheso le mongobo) a ka hlophisoa ho thibela tšenyo efe kapa efe e bakoang ke mabaka a tikoloho nakong ea leeto.

Litokomane: Litokomane tse nepahetseng tsa ho romela thepa li lokisetsoa ho fumana tumello ea lekhetho le ho latela lipalangoang, ho kenyeletsoa le bili ea thepa, setifikeiti sa tšimoloho, litifikeiti tsa boleng, le litokomane tse ling tse hlokahalang tsa taolo.

Inshorense: Ho sireletsa khahlanong le tšenyo e ka bang teng, tahlehelo, kapa bosholu nakong ea lipalangoang, ho khothaletsoa ho hlophisa inshorense bakeng sa thepa e romelloang, haholo-holo bakeng sa thepa e romelloang machabeng.

Melemo ea ho Khetha Tšepe ea Basali:

- Tlhahiso e Nepahetseng: Mekhoa ea rona ea tlhahiso ea sejoale-joale e re lumella ho fihlela mamello e thata ka ho fetisisa bakeng sa bophara, botenya ba lebota le ovality.

- Lisebelisoa tsa Boleng bo Holimo: Re fumana tšepe ea boemo bo holimo feela ho bafani ba tšepahalang, re netefatsa thepa e ntle ea mechini le ho hanyetsa mafome.

- Ho iketsetsa: Re fana ka ditharollo tse ikgethileng ho latela ditlhoko tsa bareki, ho kenyeletswa bolelele bo itseng, dikalafo tsa bokahodimo, le dikgetho tsa ho paka.

- Teko e Felletseng: Ka mekhoa ea rona e thata ea liteko, re netefatsa hore phaephe e 'ngoe le e 'ngoe e fihlela litlhoko tsohle tsa tekheniki le tsa taolo, e fana ka ts'ebetso e tšepahalang le e tšoarellang.

- Sehlopha se nang le boiphihlelo: Sehlopha sa rona sa baenjiniere le litsebi tsa theknoloji se na le boiphihlelo bo phahameng le tsebo, se netefatsa maemo a holimo tlhahisong le tšebeletsong ea bareki.

- Thomello ka Nako: Re sebetsa le netweke e tšepahalang ea thepa, re netefatsa hore thepa e romelloa ka nako karolong efe kapa efe ea lefats'e.

Qetello:

Li-tubes tsa Womic Steel tsa DIN 2391 tse se nang sekoli tse nepahetseng li tšoana le ts'ebetso e phahameng, ho tšoarella le tlhahiso e nepahetseng. Boitlamo ba rona ba boleng le khotsofalo ea bareki bo re khetholla re le moetapele tlhahisong ea liphaephe tsa tšepe. Ebang ke tsa kaho, mechini, kapa litsamaiso tsa mokelikeli, lihlahisoa tsa rona li etselitsoe ho fihlela maemo a holimo a ts'epo le matla.

Khetha Womic Steel Group e le molekane oa hau ea tšepahalang bakeng sa Liphaephe le Lisebelisoa tsa Tšepe e sa Khaotseng tsa boleng bo holimo le ts'ebetso e sa hlōloeng ea ho fana ka thepa. Rea u amohela!

Webosaete: www.womicsteel.com

Imeile: sales@womicsteel.com

Mohala/WhatsApp/WeChat: Victor: +86-15575100681 kapa Jack: +86-18390957568