Tlhaloso ea Sehlahisoa

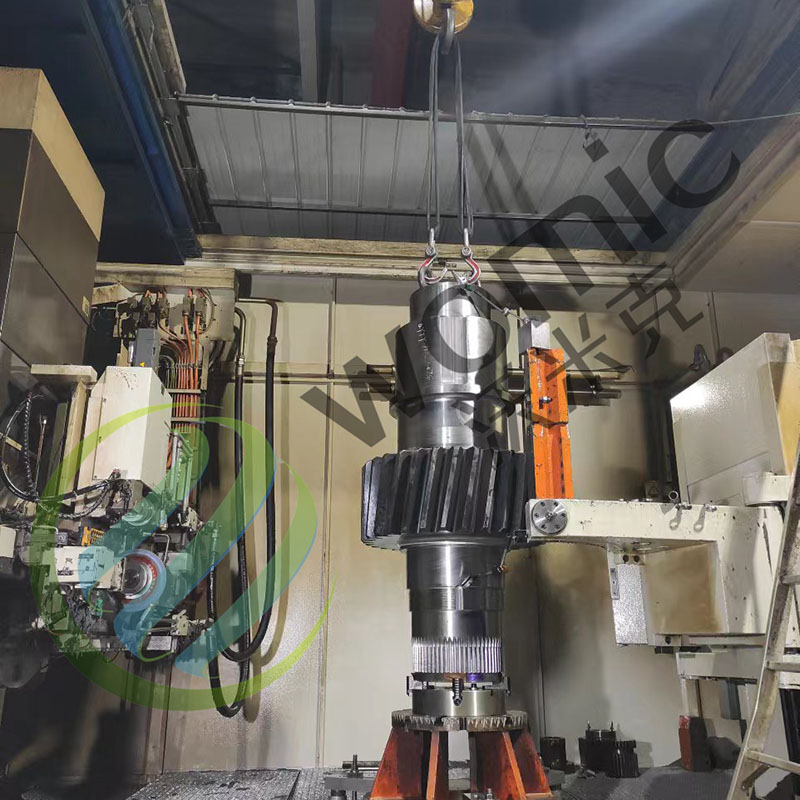

WOMIC STEEL e boetse e na le sebaka se tsebahalang sa ho etsa dihlahiswa tsa tshepe le dihlahiswa tsa tshepe tse entsweng ka leboya ho China. Dihlahiswa tse ngata tsa tshepe tse entsweng ka lejwe di fanwa lefatsheng ka bophara, jwalo ka Mexico, Amerika Borwa, Italy, Europe, United States, Japane, Russia, Asia Borwa-bochabela le tse ding. Ka boiphihlelo bo bongata ba tshepe le tshepe e entsweng ka lejwe, WOMIC STEEL e boetse e ntlafatsa theknoloji ya tshepe ka ho tswela pele. Disebediswa tse kgolo tsa ho etsa di-ball mill, mefuta e fapaneng ya di-gear, shaft ya gear, roller e tshehetsang, dipitsa tsa slag tse sebedisitsweng tsa merafo ya koporo, mechini, dikarolo tse setseng tsa shovel ya motlakase (seeta sa track), dikarolo tsa crusher (Mantles & Concave, Bowl Liners), le mohlahare o tsamayang o hlahiswang ke yona di hohetse bareki ba bangata ba mose ho maoatle ho etela k'hamphani. Mme di ba kgotsofaditse ka dihlahiswa tsa rona.

Kamora lilemo tse 20 tsa boiphihlelo ba tlhahiso le thekiso indastering ea ho lahla, joale re na le sehlopha sa botekgeniki se nang le boiphihlelo le boiphihlelo, se ikhethang tlhahisong ea li-castings tsa tšepe tse kholo le tse kholo haholo. Ts'ebetso ea tlhahiso e amohela ho tšela ka kopanelo, ho hlophisoa ha tšepe e qhibilihisitsoeng hanngoe feela ea lithane tse 450, 'me boima bo boholo ba li-castings bo ka fihla ho lithane tse ka bang 300. Indasteri ea lihlahisoa e kenyelletsa merafo, samente, likepe, forging, metallurgy, borokho, tlhokomelo ea metsi, Setsi se le seng sa machining (sehlopha) (mechini e 5 ea ho lahla le ho sila ea CNC ea TK6920, lathe e habeli ea CNC ea 13 3.15M~8M (sehlopha), mochini o le mong oa ho phutholla poleiti o boima oa CNC oa 120x3000, lisete tse 6 tsa mochini oa hobbing oa gear oa φ1.25m-8m (sehlopha)) jj.

Lisebelisoa tsa tlhahiso le lisebelisoa tsa liteko li felile. Bokhoni bo phahameng ba ho phahamisa koloi e le 'ngoe ke lithane tse 300, ka onto e le 'ngoe ea arc ea motlakase ea lithane tse 30 le lithane tse 80, onto e le 'ngoe ea ho hloekisa LF ea liteishene tse peli ea lithane tse 120, mochini o le mong oa ho phatloha ha lithupa tsa tafole o potolohang oa 10m*10m, liforo tse tharo tsa kalafo ea mocheso o phahameng tsa 12m*7m*5m, 8m*4m*3.5m, 8m*4m*3.3m, le 8m*4M *3.3m. Sebaka sa sefe sa lisebelisoa tsa ho tlosa lerōle la onto ea motlakase ea arc ea lisekoere-mithara tse 30,000.

Setsi sa liteko se ikemetseng se na le laboratori ea lik'hemik'hale, spectrometer ea ho bala ka ho toba, mochini oa tlhahlobo ea tšusumetso, mochini oa tlhahlobo ea ho tensile, sesebelisoa sa ho lemoha liphoso tsa ultrasonic, sesebelisoa sa ho hlahloba thata sa Leeb, microscope ea mohato oa Metallographic, jj.

Neng kapa neng ha re hlahloba sebakeng seo, re tla amohela tlhahlobo, e le hore o tle o lumele hore litšepe tse entsoeng ka tšepe le lihlahisoa tse entsoeng ka tšepe tse hlahisitsoeng ke WOMIC STEEL li na le boleng bo botle le bophelo bo bolelele ba tšebeletso, e leng se ka fihlelang litlhoko tsa moralo oa bareki.

E le ho rarolla boemo ba tšilafalo e phahameng le tšebeliso e phahameng ea matla,

TS'EPE EA WOMIC e sebelisa lifono tsa motlakase tse nang le maqhubu a mahareng le ho kenya libokelli tsa lerōle ka har'a workshop. Hona joale, tikoloho ea mosebetsi ea workshop e ntlafalitsoe haholo. Nakong e fetileng, coke e ne e chesoa, empa motlakase o se o sebelisoa, e leng se fokotsang tšebeliso ea matla feela, se bolokang matla le ho sireletsa tikoloho, empa hape se ntlafatsa ho nepahala ha sehlahisoa.

WOMIC STEEL e tla ntlafatsa haholo disebediswa tsa hardware tsa fektheri, ho tshehetsa disebediswa tsa othomathike, ho sebedisa mekgwa ya othomathike ya ho lata dikarolo, ho hlwekisa le ho di bentsha, le ho fafatsa ka othomathike, jj., ho eketsa tekanyo ya othomathike ya tshebetso ya tlhahiso ho feta 90%, le ho tswela pele ho ntlafatsa theknoloji.

Phapang pakeng tsa lihlahisoa tsa tšepe tse betliloeng le lihlahisoa tsa tšepe tse entsoeng ka tšepe:

Taba ea pele, mokhoa oa tlhahiso o fapane

Ts'ebetso ea tlhahiso ea li-forging le li-cast tsa tšepe e fapane. Tšepe e entsoeng ka mokhoa o sa reroang e bolela mefuta eohle ea thepa e entsoeng ka mokhoa o sa reroang le li-forging tse hlahisoang ka mokhoa oa forging; Tšepe e entsoeng ka mokhoa o sa reroang ke tšepe e sebelisetsoang ho etsa li-cast. Ho etsa li-cast ke ho phutholla thepa e tala ka sebopeho le boholo bo lakatsehang ka tšusumetso le phetoho ea polasetiki ea thepa ea tšepe. Ka lehlakoreng le leng, li-cast tsa tšepe li etsoa ka ho tšela tšepe e qhibilihisitsoeng mohlaleng o lokisitsoeng esale pele, o tiileng le ho pholisoa ho fumana sebopeho le boholo bo lakatsehang. Tšepe e entsoeng ka mokhoa o sa reroang hangata e sebelisoa tlhahisong ea likarolo tse ling tsa bohlokoa tsa mochini; Tšepe e entsoeng ka mokhoa o sa reroang e sebelisoa haholo ho etsa libopeho tse ling tse rarahaneng, tse thata ho li etsa kapa ho li khaola 'me li hloka likarolo tse matla le tsa polasetiki.

Ea bobeli, sebopeho sa thepa se fapane

Sebopeho sa thepa sa di-forging le di-cast tsa tshepe le sona se fapane. Di-forging ka kakaretso di tshwana haholo mme di na le matla a betere le ho hanyetsa mokhathala. Ka lebaka la sebopeho se teteaneng sa kristale sa di-forging, ha di na monyetla wa ho fetoha le ho petsoha ha mocheso ha di le tlasa mojaro. Ka lehlakoreng le leng, sebopeho sa tshepe e entsweng se hlephile, e leng se bonolo ho hlahisa phetoho ya polasetiki le tshenyo ya mokhathala tlasa kgato ya mojaro.

Ea boraro, litšobotsi tse fapaneng tsa ts'ebetso

Litšobotsi tsa ts'ebetso ea li-forging le li-cast le tsona lia fapana. Li-forging li na le khanyetso e phahameng ea ho tsofala le ho bola 'me li loketse matla a phahameng le meroalo e phahameng ea maqhubu. Ka lehlakoreng le leng, khanyetso ea ho tsofala le khanyetso ea ho bola ea likarolo tsa tšepe tse entsoeng ka tšepe li fokola haholo, empa li na le polasetiki e ntle.