Tlhaloso ea Sehlahisoa

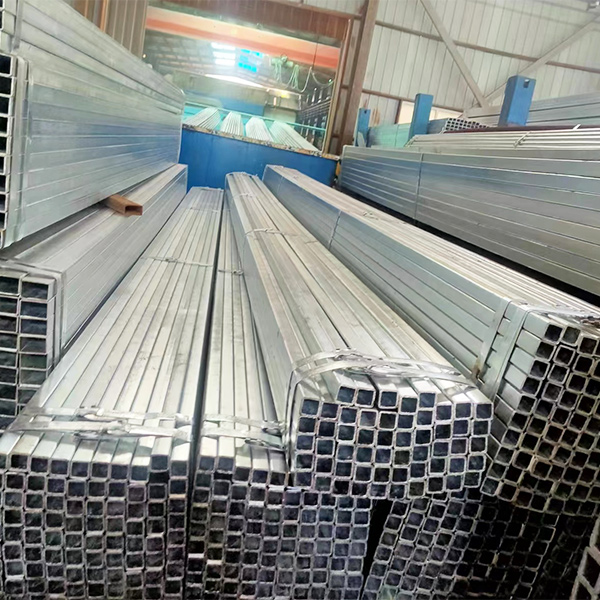

Liphaephe tsa tšepe tse entsoeng ka galvanizing ke liphaephe tsa tšepe tse hlahisoang ka ho koaheloa ka zinki e sireletsang ho thibela mafome le mafome. Phaephe ea tšepe e entsoeng ka galvanizing e ka aroloa ka phaephe ea galvanizing e chesang le phaephe ea galvanizing e entsoeng pele ho nako. Lera la galvanizing le chesang le teteaneng, le na le plating e tšoanang, le khomarelang ka matla le bophelo bo bolelele ba tšebeletso.

Liphaephe tsa sekalafo tsa tšepe le tsona ke mofuta oa liphaephe tsa galvanized ke sekalafo bakeng sa mosebetsi oa kahare le oa kantle, tse entsoeng ka tšepe ea tube. Liphaephe tsa sekalafo li bobebe, li fana ka khanyetso e tlase ea moea, 'me liphaephe tsa sekalafo li kopanngoa le ho qhaqhoa habonolo. Liphaephe tsa sekalafo tsa galvanized li fumaneha ka bolelele bo fapaneng bakeng sa bophahamo le mefuta e fapaneng ea mosebetsi.

Sistimi ea scaffolding kapa li-scaffold tsa tubula ke li-scaffold tse entsoeng ka lipeipi tsa aluminium kapa tsa tšepe tse kopantsoeng hammoho ke sehokelo se itšetlehileng ka khohlano ho tšehetsa mojaro.

Melemo ea Galvanized Steel Pipe:

Phaephe ea tšepe e entsoeng ka galvanized e boloka melemo e mengata, e sebelisoa hantle libakeng tse senyang haholo.

Melemo e meholo ea phaephe ea sebopeho sa mabati e kenyelletsa:

- E sireletsa khahlanong le mafome le mafome

- Keketseho ea nako e telele ea sebopeho

- Botšepehi bo ntlafalitsoeng ka kakaretso

- Tšireletso e theko e tlaase

- Ho bonolo ho hlahloba

- Litokiso tse fokolang

- Ho tiea ho thata

- Ho bonolo ho e hlokomela ho feta liphaephe tse tloaelehileng tse pentiloeng

- E sirelelitsoe ke maemo a ASTM a tsoetseng pele

Lipeipi tsa Tšepe tse Gantšitsoeng ka Galvanized:

- Phaephe ea tšepe e entsoeng ka galvanized ke khetho e ntle bakeng sa lits'ebetso tse ngata le mekhoa ea ts'ebetso.

Tse ling tsa lits'ebetso tse tloaelehileng bakeng sa phaephe ea tšepe ea galvanized li kenyelletsa:

- Kopano ea liphaephe

- Merero ea kaho

- Sepalangoang sa metsi a chesang le a batang

- Li-Bollards

- Liphaephe tse sebelisitsoeng li pepesitsoe

- Liphaephe tse sebelisitsoeng libakeng tsa leoatle

- Litšepe kapa Litšehetso tsa matsoho

- Litšiea tsa Fense le Fense

- Phaephe e nang le galvanized e ka boela ea sehoa, ea hotetsoa, kapa ea tjheselletsoa ka tšireletso e nepahetseng.

Phaephe ea sebopeho ea tšepe e nang le galvanized e ka boela ea sebelisoa bakeng sa mefuta e mengata ea lits'ebetso moo ho hlokahalang ho hanyetsa mafome.

Litlhaloso

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| BS 1387: Sehlopha sa A, Sehlopha sa B |

| ASTM A135/A135M: GR.A, GR.B |

| EN 10217: P195TR1 / P195TR2, P235TR1 / P235TR2, P265TR1 / P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Kereiti C250, Kereiti C350, Kereiti C450 |

| SANS 657-3: 2015 |

Maemo le Kereiti

| BS1387 | Masimo a kaho a foreimi e entsoeng ka mabone |

| API 5L PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70 | Liphaephe tsa ERW bakeng sa oli ea lipalangoang, khase ea tlhaho |

| ASTM A53: GR.A, GR.B | Liphaephe tsa Tšepe tsa ERW bakeng sa meaho le kaho |

| ASTM A252 ASTM A178 | Liphaephe tsa Tšepe tsa ERW bakeng sa merero ea kaho ea ho tlatsa lipeipi |

| AN/NZS 1163 AN/NZS 1074 | Liphaephe tsa Tšepe tsa ERW bakeng sa merero ea kaho ea meaho |

| EN10219-1 S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | Liphaephe tsa ERW tse sebelisetsoang ho fetisa maro ka khatello e tlase / e mahareng joalo ka oli, khase, mouoane, metsi, moea |

| ASTM A500/501, ASTM A691 | Liphaephe tsa ERW bakeng sa ho fetisa metsi |

| EN10217-1, S275, S275JR, S355JRH, S355J2H | |

| ASTM A672 | Liphaephe tsa ERW bakeng sa tšebeliso ea khatello e phahameng |

| ASTM A123/A123M | bakeng sa masela a koahetsoeng ka galvanized a chesang holim'a tšepe e sa ruseng le lihlahisoa tsa tšepe e koahetsoeng ka galvanized |

| ASTM A53/A53M: | Phaephe e ntšo e se nang sekoli le e phuthetsoeng ka tšepe e ntsho, e qoelitsoeng ka galvanized e chesang le e ntšo e koahetsoeng bakeng sa merero e akaretsang. |

| EN 10240 | bakeng sa dikoahelo tsa tshepe, ho kenyeletswa le galvanizing, tsa diphaephe tsa tshepe tse se nang moedi le tse welilweng. |

| EN 10255 | ho fetisa metsi a seng kotsi, ho kenyeletsoa le sekoahelo se qhibilihisitsoeng ka galvanized se chesang. |

Taolo ea Boleng

Tlhahlobo ea Lisebelisoa tse Tala, Tlhahlobo ea Lik'hemik'hale, Teko ea Mechanical, Tlhahlobo ea Pono, Teko ea Khatello, Tlhahlobo ea Tekanyo, Teko ea Kobeha, Teko ea ho Fokotsa, Teko ea Tšusumetso, Teko ea DWT, Teko ea NDT, Teko ea Hydrostatic, Teko ea ho Tiea…..

Ho tšoaea, ho penta pele ho pepa.

Ho paka le ho Romela

Mokhoa oa ho paka liphaephe tsa tšepe o kenyelletsa ho hloekisa, ho li hlopha ka lihlopha, ho li phuthela, ho li kopanya, ho li tiisa, ho li ngola, ho li kenya ka har'a liphaephe (haeba ho hlokahala), ho li kenya ka har'a lijana, ho li beha ka har'a liphaephe, ho li koala, ho li tsamaisa le ho li pakolla. Mefuta e fapaneng ea liphaephe tsa tšepe le li-fittings tse nang le mekhoa e fapaneng ea ho li paka. Ts'ebetso ena e felletseng e netefatsa hore liphaephe tsa tšepe lia romelloa le ho fihla moo li eang teng li le boemong bo botle, li loketse ts'ebeliso ea tsona e reriloeng.

Tšebeliso le Tšebeliso

Phaephe e entsoeng ka galvanized ke phaephe ea tšepe e kentsoeng ka galvanized e chesang 'me e koahetsoe ka lera la zinki ho ntlafatsa khanyetso ea eona ea mafome le bophelo ba ts'ebeletso. Phaephe e entsoeng ka galvanized e na le mefuta e mengata ea ts'ebeliso libakeng tse fapaneng, ho kenyeletsoa empa ho sa felle feela ho:

1. Tšimo ea kaho:

Liphaephe tse entsoeng ka galvanized hangata li sebelisoa mehahong ea meaho, joalo ka li-handrails tsa litepisi, litereiling, liforeimi tsa meaho ea tšepe, jj. Ka lebaka la ho hanyetsa ho bola ha lera la zinki, liphaephe tse entsoeng ka galvanized li ka sebelisoa kantle le libakeng tse mongobo nako e telele 'me ha li na mafome.

2. Phepelo ea metsi le litsamaiso tsa drainage:

Liphaephe tse entsoeng ka galvanized li sebelisoa haholo tsamaisong ea phepelo ea metsi le ea drainage ho tsamaisa metsi a nooang, metsi a indasteri le likhoerekhoere. Ho hanyetsa mafome ho etsa hore e be khetho e tšepahalang bakeng sa ho fokotsa mathata a ho thibana ha liphaephe le mafome.

3. Phetiso ea Oli le Khase:

Phaephe e entsoeng ka galvanized e sebelisoa hangata lits'ebetsong tsa liphaephe tse tsamaisang oli, khase ea tlhaho, le lintho tse ling tse metsi kapa likhase. Lera la zinki le sireletsa liphaephe khahlanong le mafome le oxidation tikolohong.

4. Mekhoa ea HVAC:

Liphaephe tse entsoeng ka galvanized li boetse li sebelisoa lits'ebetsong tsa ho futhumatsa, ho kenya moea le ho pholisa moea. Kaha lits'ebetso tsena li tlas'a maemo a fapaneng a tikoloho, ho hanyetsa ho bola ha phaephe e entsoeng ka galvanized ho ka eketsa nako ea ts'ebeletso ea eona.

5. Litšireletso tsa Tsela:

Liphaephe tse entsoeng ka galvanized hangata li sebelisoa ho etsa litšepe tsa tšireletso ea litsela ho fana ka polokeho ea sephethephethe le ho tšoaea meeli ea litsela.

6. Lekala la Merafo le Liindasteri:

Lefapheng la merafo le indasteri, liphaephe tsa galvanized li sebelisoa ho tsamaisa lirafshoa, thepa e tala, lik'hemik'hale, jj. Ho hanyetsa mafome le matla a eona ho etsa hore e lokele ho sebelisoa libakeng tsena tse thata.

7. Masimo a temo:

Liphaephe tse entsoeng ka galvanized le tsona li sebelisoa haholo masimong a temo, joalo ka liphaephe tsa mekhoa ea ho nosetsa polasing, ka lebaka la bokhoni ba tsona ba ho hanela ho bola mobung.

Ka bokhutšoanyane, liphaephe tsa galvanised li na le lits'ebetso tsa bohlokoa masimong a mangata a fapaneng, ho tloha kahong ho ea meralong ea motheo ho ea indastering le temong ka lebaka la ho hanyetsa mafome le ho tenyetseha ha tsona.

Liphaephe tsa tšepe li sebetsa e le mokokotlo oa boenjiniere ba indasteri le ba sechaba ba sejoale-joale, li tšehetsa mefuta e mengata ea lits'ebetso tse tlatsetsang nts'etsopele ea lichaba le moruo lefatšeng ka bophara.

Liphaephe tsa tšepe le lisebelisoa tseo re li hlahisitseng Womic Steel li sebelisoa haholo bakeng sa peterole, khase, mafura le liphaephe tsa metsi, liphaephe tsa leoatle le tsa kaho, ho cheka, merero ea kaho ea tšepe, ho bokella le borokho, hape le liphaephe tsa tšepe tse nepahetseng bakeng sa tlhahiso ea li-roller tsa conveyor, jj.