Tlhaloso ea Sehlahisoa

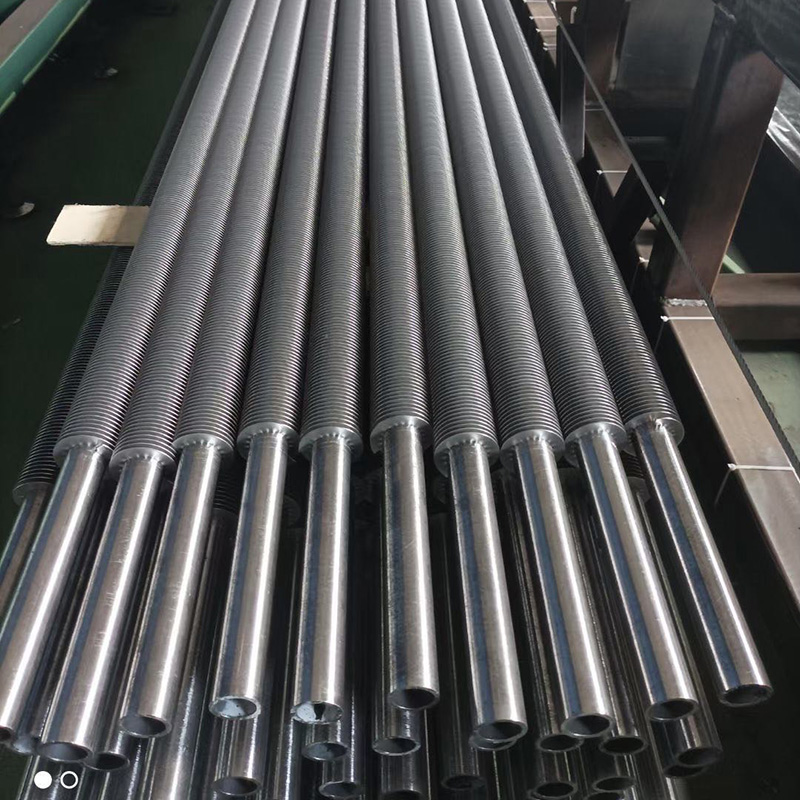

Litlhaloso tsa phaephe ea boiler ea tšepe tse nang le litekanyo tse akaretsang (joalo ka bophara kapa bolelele) le botenya ba lebota, phaephe ea boiler ea tšepe e ka sebelisoa liphaepheng, lisebelisoa tsa theknoloji ea mocheso, mechini ea indasteri, lipatlisiso tsa jeoloji ea peterole, lijana, indasteri ea lik'hemik'hale le merero e meng e ikhethang.

Liphaephe tsa tšepe tsa boiler li etsoa ka liphaephe tse se nang moqhaka, li entsoe ka thepa ea tšepe ea khabone kapa tšepe ea alloy. Liphaephe tsa boiler li sebelisoa haholo liphaepheng tsa mouoane, liphaepheng tsa mocheso, ho kopanya motlakase, lifemeng tsa mafura a mesaletsa ea lintho tsa khale, lifemeng tsa ts'ebetso ea indasteri, lifemeng tsa motlakase, lifemeng tsa tlhahiso ea tsoekere jj. Liphaephe tsa boiler kapa liphaephe tse atisang ho sebelisoa e le liphaephe tsa boiler tse nang le khatello e mahareng kapa tsa boiler tse nang le khatello e phahameng.

Litlhaloso

| ASTM A179 |

| ASTM A192 |

| ASTM A209: Gr.T1, Gr. T1a, Gr. T1b |

| ASTM A210:Gr.A1, Gr.C |

| ASTM A106: Gr.A, Gr.B, Gr.C |

| DIN 17175: ST35.8, ST45.8, 15Mo3, 13CrMo44 |

| EN 10216-2: P235GH, P265GH, 16Mo3, 10CrMo5-5, 13CrMo4-5 |

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A178:Gr.A, Gr.C |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Kreiti ya 1, Kreiti ya 3, Kreiti ya 4, Kreiti ya 6, Kreiti ya 7, Kreiti ya 8, Kreiti ya 9. Kreiti ya 10, Kreiti ya 11 |

| ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H jj... |

| ASTM A269/A269M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H jj... |

| EN 10216-5: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 |

Maemo le Kereiti

Litekanyetso tsa Liphaephe tsa BoilerMekhahlelo:

ASME SA-179M, ASME SA-106, ASTM A178, ASME SA-192M, EN10216-1, JIS G3461, ASME SA-213M, DIN17175, DIN1629.

Boemo ba ho Romelloa: E annealed, e tloaelehile, e halefisitsoe. Bokaholimo bo tlotsitsoe ka oli, bo pentiloe ka botsho, bo tjhesitswe ka ho thunya, e kentswe ka galvanized e tjhesang.

| ASME SA-179M: | Sesebediswa sa ho fapanyetsana mocheso le diphaephe tsa Condenser tse hulang ka serame tse se nang sekoli. |

| ASME SA-106: | Pipe ea Tšepe ea Khabone Bakeng sa Tšebeletso ea Mocheso o Phahameng. |

| ASTM A178: | Tšepe ea Khabone e Welded e Haneloang ke Motlakase le Boiler ea Tšepe ea Khabone le Manganese le Liphaephe tsa Superheater. |

| ASME SA-192M: | Liphaephe tsa Boiler tsa Tšepe ea Khabone tse se Nang Seamless bakeng sa Lisebelisoa tsa Khatello e Phahameng. |

| ASME SA-210M: | Boiler ea Tšepe ea Khabone e Mahareng e se nang Seamless le Liphaephe tsa Superheater. |

| EN10216-1/2: | Liphaephe tsa tšepe tse sa tsoakoang tse se nang mohele bakeng sa merero ea khatello tse nang le litšobotsi tse boletsoeng tsa mocheso oa kamore. |

| JIS G3454: | Liphaephe tsa tšepe ea khabone bakeng sa tšebeletso ea khatello mochesong o ka bang 350 Degrees Celsius |

| JIS G3461: | Liphaephe tsa Tšepe ea Khabone bakeng sa Boiler le Mochini o Fetolang Mocheso. |

| GB 5310: | Liphaephe tsa tšepe tse se nang seamless bakeng sa boiler ea khatello e phahameng. |

| ASME SA-335M: | Boiler ea tšepe ea ferritic le austenitic e se nang seamless, superheater le tube ea ho fapanyetsana mocheso. |

| ASME SA-213M: | Liphaephe tsa Tšepe ea Alloy bakeng sa liboiler, li-superheater le li-heat exchanger. |

| DIN 17175: | Liphaephe tsa Tšepe tse se nang Mohele bakeng sa Indasteri ea Boiler, phaephe ea tšepe e se nang mohele e hanelang mocheso, e sebelisetsoang liphaephe tsa indasteri ea boiler. |

| DIN 1629: | Liboiler tse chesang haholo, liphaephe tsa tlhahiso, sekepe, lisebelisoa, liphaephe tse kenngoang, le joalo ka liphaephe tsa austenitic. |

Taolo ea Boleng

Tlhahlobo ea Lisebelisoa tse Tala, Tlhahlobo ea Lik'hemik'hale, Teko ea Mechanical, Tlhahlobo ea Pono, Teko ea Khatello, Tlhahlobo ea Tekanyo, Teko ea Kobeha, Teko ea ho Fokotsa, Teko ea Tšusumetso, Teko ea DWT, Teko ea NDT, Teko ea Hydrostatic, Teko ea ho Tiea…..

Ho tšoaea, ho penta pele ho pepa.

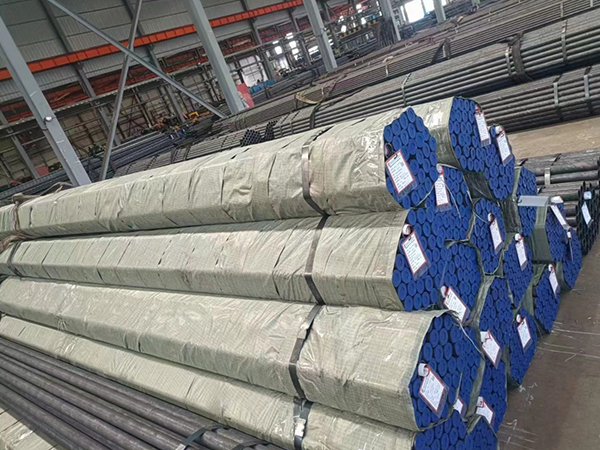

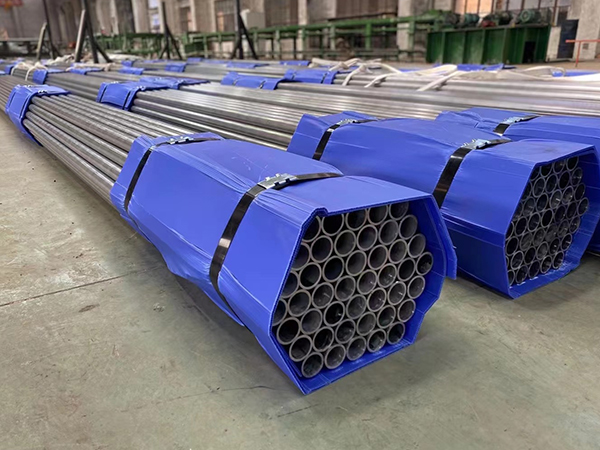

Ho paka le ho Romela

Mokhoa oa ho paka liphaephe tsa tšepe o kenyelletsa ho hloekisa, ho li hlopha ka lihlopha, ho li phuthela, ho li kopanya, ho li tiisa, ho li ngola, ho li kenya ka har'a liphaephe (haeba ho hlokahala), ho li kenya ka har'a lijana, ho li beha ka har'a liphaephe, ho li koala, ho li tsamaisa le ho li pakolla. Mefuta e fapaneng ea liphaephe tsa tšepe le li-fittings tse nang le mekhoa e fapaneng ea ho li paka. Ts'ebetso ena e felletseng e netefatsa hore liphaephe tsa tšepe lia romelloa le ho fihla moo li eang teng li le boemong bo botle, li loketse ts'ebeliso ea tsona e reriloeng.

Tšebeliso le Tšebeliso

Liphaephe tsa tšepe li sebetsa e le mokokotlo oa boenjiniere ba indasteri le ba sechaba ba sejoale-joale, li tšehetsa mefuta e mengata ea lits'ebetso tse tlatsetsang nts'etsopele ea lichaba le moruo lefatšeng ka bophara.

Liphaephe tsa tšepe le lisebelisoa tseo re li hlahisitseng Womic Steel li sebelisoa haholo bakeng sa peterole, khase, mafura le liphaephe tsa metsi, liphaephe tsa leoatle le tsa kaho, ho cheka, merero ea kaho ea tšepe, ho bokella le borokho, hape le liphaephe tsa tšepe tse nepahetseng bakeng sa tlhahiso ea li-roller tsa conveyor, jj.