Tlhaloso ea Sehlahisoa

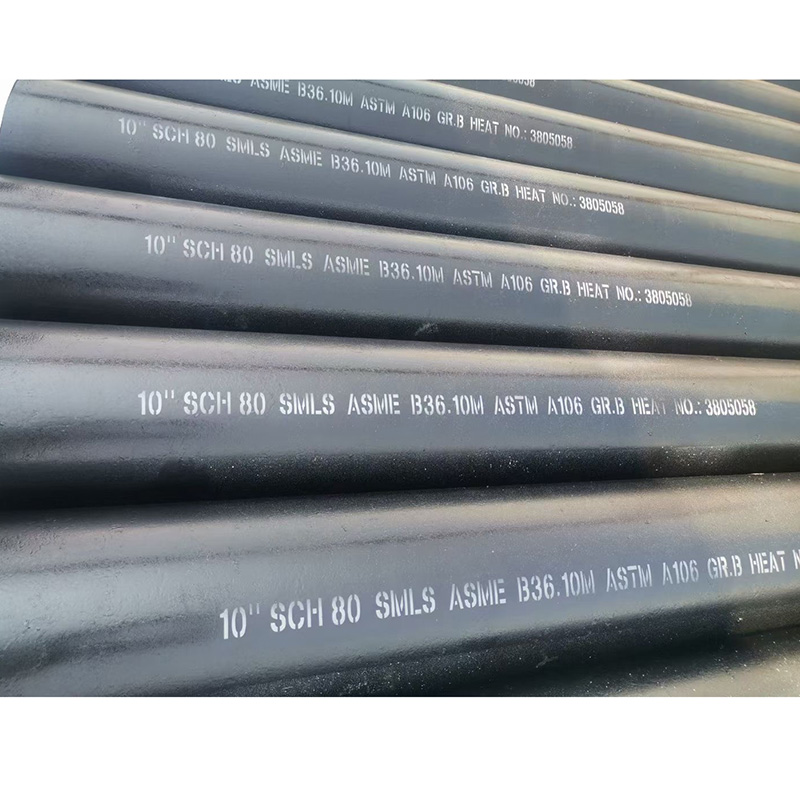

Phaephe ea tšepe e se nang seam ke phaephe ea tšepe kapa lipeipi tse se nang weld-seam kapa weld-joint. Liphaephe tsa tšepe ea carbon tse se nang seam li hlahisoa ke li-ingot tsa tšepe kapa li-blanks tsa tube tse tiileng tse phunyeletsoeng ka har'a lipeipi tsa capillary, ebe li etsoa ka ho phunya ho chesang, ho phunya ho batang kapa ho hula ho batang, ka litšobotsi tse ntle tsa ho tšoarella hantle le ho hanyetsa mafome.

Phaephe ea tšepe e se nang seamless ea khabone ke karolo ea tšubuhlellano kapa silindara ea karolo e se nang letho, hangata e sebelisoa haholo ho fetisa kapa ho fetisetsa metsi le likhase (metsi), phofo le tse ling tse kang lintho tse nyenyane tse tiileng.

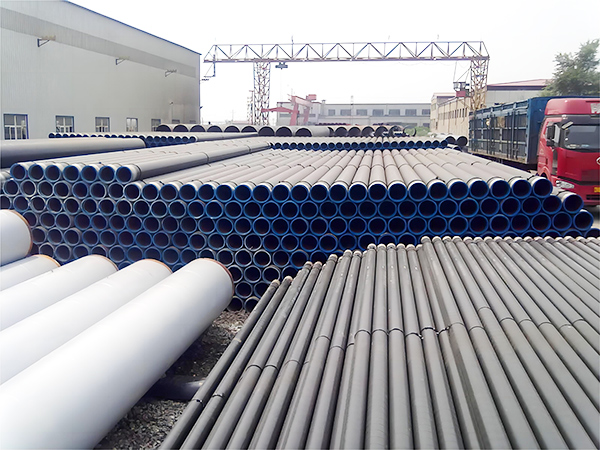

Womic e fana ka phaephe ea tšepe e se nang moedi bakeng sa Merero ea Kaho ea Lebopong/Lebopong, Ho kenyeletsoa liphaephe tse se nang moedi tse phutholohileng tse chesang le liphaephe tse batang tse huloang (tse phutholohileng) tse se nang moedi.

Litlhaloso

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210 :S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Kreiti ya 1, Kreiti ya 3, Kreiti ya 4, Kreiti ya 6, Kreiti ya 7, Kreiti ya 8, Kreiti ya 9. Kreiti ya 10, Kreiti ya 11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1 : P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163 :10#,20#,Q345 |

| GB/T 8162 :10#,20#,35#,45#,Q345 |

Maemo le Kereiti

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 | Phaephe ea tšepe e se nang seamless ea khabone bakeng sa phaephe ea mohala, Petroleum, liindasteri tsa khase ea tlhaho, litsamaiso tsa lipalangoang tsa liphaephe. |

| API 5CT: J55, K55, N80, L80, P110 | Phaephe ea tšepe e se nang seamless ea khase ea oli bakeng sa ho kenya le ho kenya liphaephe. |

| API 5D: E75, X95, G105, S135 | Liphaephe tsa ho phunya, liphaephe tsa ho phunya oli le khase. |

| EN10210 :S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | Phaephe ea tšepe e se nang seamless ea khabone bakeng sa projeke ea kaho. |

| ASTM A106: GR.A, GR.B, GR.C | Phaephe ea tšepe e se nang seamless ea khabone bakeng sa projeke ea kaho. |

| ASTM A53/A53M: GR.A, GR.B | Phaephe ea tšepe e se nang seamless ea khabone bakeng sa projeke ea kaho. |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 | Phaephe ea tšepe e se nang seamless ea k'habone bakeng sa indasteri ea litšebeletso tsa mocheso o phahameng. |

| ASTM A333: Kreiti ya 1, Kreiti ya 3, Kreiti ya 4, Kreiti ya 6, Kreiti ya 7, Kreiti ya 8, Kreiti ya 9. Kreiti ya 10, Kreiti ya 11 | Phaephe ea tšepe e se nang seamless ea k'habone bakeng sa indasteri ea mocheso o tlase. |

| DIN 2391: St30Al, St30Si, St35, St45, St52 | Phaephe ea pele e se nang seamless e huloang ke carbon |

| DIN EN 10216-1 : P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 | Liphaephe tsa tšepe tse se nang mohele tse chitja tse sa kenngoeng tse ipapisitseng le litlhoko tse khethehileng |

| GB/T 8163 :10#, 20#, Q345 | Phaephe ea tšepe e se nang seamless ea carbon bakeng sa tšebeliso e tloaelehileng. |

| GB/T 8162 :10#, 20#, 35#, 45#, Q345 | Phaephe ea tšepe e se nang seamless ea carbon bakeng sa tšebeliso e tloaelehileng. |

Taolo ea Boleng

Tlhahlobo ea Lisebelisoa tse Tala, Tlhahlobo ea Lik'hemik'hale, Teko ea Mechini, Tlhahlobo ea Pono, Teko ea Khatello, Tlhahlobo ea Tekanyo, Teko ea Kobeha, Teko ea ho Fokotsa, Teko ea Tšusumetso, Teko ea DWT, Teko ea NDT, Teko ea Hydrostatic, Teko ea ho Tiea jj. …..

Ho tšoaea, ho penta pele ho pepa.

Ho paka le ho Romela

Mokhoa oa ho paka liphaephe tsa tšepe o kenyelletsa ho hloekisa, ho li hlopha ka lihlopha, ho li phuthela, ho li kopanya, ho li tiisa, ho li ngola, ho li kenya ka har'a liphaephe (haeba ho hlokahala), ho li kenya ka har'a lijana, ho li beha ka har'a liphaephe, ho li koala, ho li tsamaisa le ho li pakolla. Mefuta e fapaneng ea liphaephe tsa tšepe le li-fittings tse nang le mekhoa e fapaneng ea ho li paka. Ts'ebetso ena e felletseng e netefatsa hore liphaephe tsa tšepe lia romelloa le ho fihla moo li eang teng li le boemong bo botle, li loketse ts'ebeliso ea tsona e reriloeng.

Tšebeliso le Tšebeliso

Liphaephe tsa tšepe li sebetsa e le mokokotlo oa boenjiniere ba indasteri le ba sechaba ba sejoale-joale, li tšehetsa mefuta e mengata ea lits'ebetso tse tlatsetsang nts'etsopele ea lichaba le moruo lefatšeng ka bophara.

Liphaephe tsa tšepe le lisebelisoa tseo re li hlahisitseng Womic Steel li sebelisoa haholo bakeng sa peterole, khase, mafura le liphaephe tsa metsi, liphaephe tsa leoatle le tsa kaho, ho cheka, merero ea kaho ea tšepe, ho bokella le borokho, hape le liphaephe tsa tšepe tse nepahetseng bakeng sa tlhahiso ea li-roller tsa conveyor, jj.