Tlhaloso ea Sehlahisoa

Tlhahisoleseding e Tloaelehileng - ASME/ANSI B16.5 & B16.47 - Li-Flanges tsa Liphaephe le Lisebelisoa tse Fetotsoeng

Tekanyetso ea ASME B16.5 e akaretsa likarolo tse fapaneng tsa li-flange tsa liphaephe le li-fitting tse nang le li-flange, ho kenyeletsoa litekanyetso tsa khatello le mocheso, thepa, litekanyo, mamello, ho tšoaea, ho leka le ho khetholla li-openings bakeng sa likarolo tsena. Tekanyetso ena e kenyelletsa li-flange tse nang le mabitso a sehlopha sa litekanyetso ho tloha ho 150 ho isa ho 2500, tse koahelang boholo ho tloha ho NPS 1/2 ho isa ho NPS 24. E fana ka litlhoko liyuniting tsa metric le US. Ho bohlokoa ho hlokomela hore tekanyetso ena e lekanyelitsoe ho li-flange le li-fitting tse nang le li-flange tse entsoeng ka thepa e entsoeng ka cast kapa forged, ho kenyeletsoa li-flange tse foufetseng le li-flange tse itseng tse fokotsang tse entsoeng ka thepa e entsoeng ka cast, forged, kapa plate.

Bakeng sa diphaephe tse nang le diphaephe le di-fitting tse nang le diphaephe tse fetang 24" NPS, ASME/ANSI B16.47 e lokela ho ba le tshupiso.

Mefuta e Tloaelehileng ea Flange

● Li-Flanges tse Thellang: Li-flange tsena hangata li tlatsitsoe ka har'a ANSI Class 150, 300, 600, 1500 le 2500 ho fihlela ho 24" NPS. Li "thelletsoe holim'a" lipheletso tsa phaephe kapa tsa ho li kopanya 'me li tjheselletsoa sebakeng sa tsona, ho lumella li-weld tsa fillet kahare le kantle ho flange. Mefuta ea ho fokotsa e sebelisoa ho fokotsa boholo ba mela ha sebaka se lekanyelitsoe.

● Li-Flanges tsa Molala oa Weld: Li-flanges tsena li na le hub e telele e fapaneng e nang le moqomo o mosesaane le phetoho e boreleli ea botenya, e netefatsang khokahano e felletseng ea weld ho phaephe kapa ho kenya. Li sebelisoa maemong a boima a ts'ebeletso.

● Li-Flanges tsa Mahlakore a Kopanetsoeng: Li kopantsoe le ntlha ea stub, li-flanges tsa mahlakore a kopanetsoeng li thellisoa holim'a ho kenya ntlha ea stub 'me li hokahanngoa ka ho tjheseletsa kapa mekhoa e meng. Moralo oa tsona o hlephileng o lumella ho lokisoa habonolo nakong ea ho kopanya le ho qhaqha.

● Li-Flanges tsa ho Thusa: Li-flange tsena ha li na sefahleho se phahamisitsoeng 'me li sebelisoa le masale a ho Thusa, li fana ka litharollo tse theko e tlaase bakeng sa likhokahano tsa li-flange.

● Li-Flanges tse nang le khoele (tse nang le screw): Li khathetse ho lekana le phaephe e itseng ka hare ho bophara, li-flanges tse nang le khoele li entsoe ka likhoele tsa phaephe tse nang le khoele ka lehlakoreng le ka morao, haholo-holo bakeng sa liphaephe tse nyane tse nang le khoele.

● Li-flange tsa Socket Weld: Li tšoana le li-flange tse thellang, li-flange tsa socket weld li etsoa ka mochini ho lekana le li-socket tsa boholo ba phaephe, e leng se lumellang ho tjheseletsa li-fillet ka lehlakoreng le ka morao ho tiisa khokahano. Hangata li sebelisoa bakeng sa liphaephe tse nyane tsa bore.

● Li-Flang tse Foufetseng: Li-flange tsena ha li na lesoba le bohareng 'me li sebelisetsoa ho koala kapa ho thibela qetello ea sistimi ea liphaephe.

Tsena ke tse ling tsa mefuta e tloaelehileng ea li-flange tsa liphaephe tse sebelisoang lits'ebetsong tse fapaneng tsa indasteri le tsa khoebo. Khetho ea mofuta oa flange e itšetlehile ka lintlha tse kang khatello, mocheso le mofuta oa mokelikeli o tsamaisoang, hammoho le litlhoko tse itseng tsa projeke. Khetho e nepahetseng le ho kenngoa ha li-flange ke tsa bohlokoa bakeng sa ts'ebetso e sireletsehileng le e sebetsang hantle ea litsamaiso tsa liphaephe.

Litlhaloso

| ASME B16.5: Tšepe ea Khabone, Tšepe e sa Ruseng, Tšepe e kopantsoeng |

| EN 1092-1: Tšepe ea Khabone, Tšepe e sa Ruseng, Tšepe e kopantsoeng |

| DIN 2501: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| GOST 33259: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| SABS 1123: Tšepe ea Khabone, Tšepe e sa Ruseng, Tšepe e kopantsoeng |

Lisebelisoa tsa Flange

Li-flange li kopanngoa ho phaephe le nozzle ea lisebelisoa. Ka hona, e entsoe ka thepa e latelang;

● Tšepe ea k'habone

● Tšepe e tlaase ea alloy

● Tšepe e sa ruseng

● Motsoako oa thepa e sa tloaelehang (Stub) le thepa e 'ngoe e tšehetsang

Lethathamo la thepa e sebelisoang tlhahisong le akaretsoa ho ASME B16.5 le B16.47.

● ASME B16.5 -Li-Flanges tsa Liphaephe le Li-Flanged Fittings NPS ½” ho isa ho 24”

● ASME B16.47 -Li-Flanges tsa Tšepe tse Bophara bo Boholo NPS 26” ho isa ho 60”

Lisebelisoa tse sebelisoang hangata tsa ho betla ke

● Tšepe ea Khabone: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Tšepe e kopantsoeng: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Tšepe e sa Hloekeng: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Litekanyo tsa Flange tsa Sehlopha sa 150

| Boholo ka lisenthimithara | Boholo ka mm | Dia ea Kantle. | Flange e teteaneng. | OD ea Setsi | Bolelele ba Flange | RF Dia. | Bophahamo ba RF | PCD | Sekoti sa Socket | Palo ea Libolt | Boholo ba Bolt UNC | Bolelele ba Bolt ea Mochini | Bolelele ba RF Stud | Boholo ba Lesoba | Boholo ba ISO Stud | Boima ba 'mele ka kg |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Sehlopha sa 150 Weld Neck Flange Litekanyo

| Boholo ka lisenthimithara | Boholo ka mm | Bophara ba Kantle | Botenya ba Flange | OD ea Setsi | Molala o Welded OD | Bolelele ba Molala oa ho Tjheseletsa | Bore | Bophara ba RF | Bophahamo ba RF | PCD | Sefahleho se Welded |

|

|

| A | B | C | D | E | F | G | H | I | J |

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Sekoti sa molala sa ho tjheseletsa se nkiloe kemisong ea liphaephe | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Litekanyo tsa Flange tse foufetseng tsa sehlopha sa 150

| Boholo | Boholo | Kantle | Sekoahelo | RF | RF | PCD | Palo ea | Boholo ba Bolutu | Mochini oa Bolt | RF Stud | Boholo ba Lesoba | Sekoti sa ISO | Boima ba 'mele |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Maemo le Kereiti

| ASME B16.5: Li-Flanges tsa Liphaephe le Lisebelisoa tse Fetotsoeng | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| EN 1092-1: Li-Flanges le Manonyeletso a Tsona - Li-Flanges tse chitja bakeng sa Liphaephe, Li-valve, Lisebelisoa le Lisebelisoa, PN e Khethiloeng - Karolo ea 1: Li-Flanges tsa Tšepe | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng

|

| DIN 2501: Li-Flanges le Manonyeletso a Mehele | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| GOST 33259: Li-Flanges bakeng sa Li-valve, Lisebelisoa le Liphaephe bakeng sa Khatello ho PN 250 | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| SABS 1123: Li-Flanges bakeng sa Liphaephe, Li-valve le Lisebelisoa | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

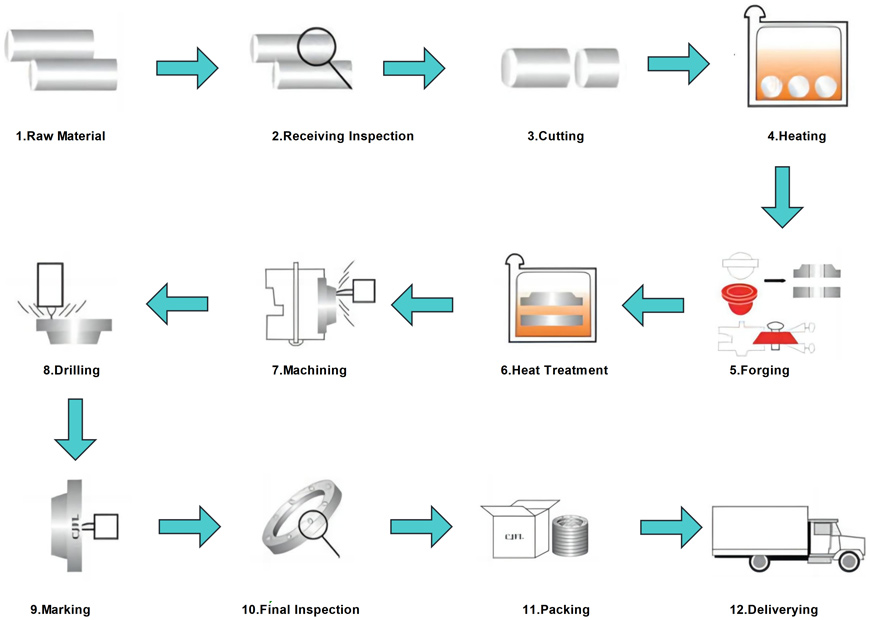

Mokhoa oa Tlhahiso

Taolo ea Boleng

Tlhahlobo ea Lisebelisoa tse Tala, Tlhahlobo ea Lik'hemik'hale, Teko ea Mekaniki, Tlhahlobo ea Pono, Tlhahlobo ea Tekanyo, Teko ea ho Kobeha, Teko ea ho Foforeha, Teko ea Tšusumetso, Teko ea DWT, Tlhahlobo e sa Senyeheng (UT, MT, PT, X-Ray,), Teko ea ho Tiea, Teko ea Khatello, Teko ea ho Lutla ha Litulo, Teko ea Metallography, Teko ea ho Sila, Teko ea ho Hanela Mollo, Teko ea Spray ea Letsoai, Teko ea Ts'ebetso ea Phallo, Teko ea Torque le Thrust, Tlhahlobo ea ho Penta le ho Koahela, Tlhahlobo ea Litokomane…..

Tšebeliso le Tšebeliso

Li-flange ke likarolo tsa bohlokoa tsa indasteri tse sebelisetsoang ho hokela liphaephe, li-valve, lisebelisoa le likarolo tse ling tsa liphaephe. Li bapala karolo ea bohlokoa ho hokela, ho tšehetsa le ho koala litsamaiso tsa liphaephe. Li-flange li sebetsa e le likarolo tsa bohlokoa lits'ebetsong tse fapaneng tsa indasteri, ho kenyeletsoa:

● Mekhoa ea ho Phaepha

● Li-valve

● Lisebelisoa

● Likhokahano

● Ho koala

● Taolo ea Khatello

Ho paka le ho Romela

Ho Womic Steel, re utloisisa bohlokoa ba ho paka ka mokhoa o sireletsehileng le ho romela thepa ka mokhoa o tšepahalang ha ho tluoa tabeng ea ho tlisa liphaephe tsa rona tsa boleng bo holimo monyako oa hau. Mona ke kakaretso ea mekhoa ea rona ea ho paka le ho romella thepa bakeng sa litšupiso tsa hau:

Sephutheloana:

Liphaephe tsa rona tsa liphaephe li phuthetsoe ka hloko ho netefatsa hore li fihla ho uena li le boemong bo phethahetseng, li loketse litlhoko tsa hau tsa indasteri kapa tsa khoebo. Ts'ebetso ea rona ea ho paka e kenyelletsa mehato ea bohlokoa e latelang:

● Tlhahlobo ea Boleng: Pele ho liphutheloana, li-flange tsohle li hlahlojoa ka botlalo ho netefatsa hore li fihlela litekanyetso tsa rona tse thata tsa ts'ebetso le botšepehi.

● Sekoahelo se Sireletsang: Ho latela mofuta oa thepa le ts'ebeliso, li-flange tsa rona li ka fumana sekoahelo se sireletsang ho thibela ho bola le tšenyo nakong ea lipalangoang.

● Ho Tlama ka Tšireletseho: Li-flange li tlameletsoe hammoho ka mokhoa o sireletsehileng, ho netefatsa hore li lula li tsitsitse ebile li sirelelitsoe nakong eohle ea ts'ebetso ea ho romella.

● Ho Ngola le ho Fana ka Litokomane: Sephutheloana se seng le se seng se ngotswe ka ho hlaka ka tlhahisoleseding ya bohlokwa, ho kenyeletswa le ditlhaloso tsa sehlahiswa, bongata, le ditaelo dife kapa dife tse ikgethang tsa ho sebetsana le sona. Ditokomane tse amehang, tse kang disetifikeiti tsa ho latela melao, le tsona di a kenyeletswa.

● Sephutheloana se Ikhethileng: Re ka amohela likopo tse khethehileng tsa ho paka ho latela litlhoko tsa hau tse ikhethang, re netefatsa hore li-flange tsa hau li lokisitsoe hantle kamoo ho hlokahalang.

Ho tsamaisa ka sekepe:

Re sebelisana 'moho le balekane ba tšepahalang ba ho romela thepa ho netefatsa hore thepa e tla romelloa ka mokhoa o tšepahalang le o nakong sebakeng seo u se boletseng. Sehlopha sa rona sa thepa se ntlafatsa litsela tsa ho romela thepa ho fokotsa linako tsa ho tsamaisa thepa le ho fokotsa kotsi ea tieho. Bakeng sa thepa ea machabeng, re sebetsana le litokomane tsohle tse hlokahalang tsa thepa ea lekgetho le ho latela melao ho nolofatsa ho tlosoa ha thepa ea lekgetho ka mokhoa o boreleli. Re fana ka likhetho tse feto-fetohang tsa ho romela thepa, ho kenyeletsoa le ho romelloa ka potlako bakeng sa litlhoko tse potlakileng.