Tlhaloso ea Sehlahisoa

Sefokotsi:

Sefokotsi sa phaephe ya tshepe se sebetsa e le karolo ya bohlokwa ya phaephe, se nolofalletsang phetoho e se nang sekoli ho tloha boholong bo boholo ho ya ho bo bonyenyane ho ya ka dipehelo tsa bophara ba kahare.

Ho na le mefuta e 'meli ea mantlha ea li-reducer: tse bohareng le tse sa tloaelehang. Li-reducer tse bohareng li etsa hore ho fokotsoe boholo ba mokoti o lekanang, ho netefatsa hore ho hokahana ha mela e bohareng ea liphaephe ho hokahane. Sebopeho sena se loketse ha ho boloka sekhahla se ts'oanang sa phallo se le bohlokoa. Ka lehlakoreng le leng, li-reducer tse sa tloaelehang li hlahisa karohano pakeng tsa mela e bohareng ea liphaephe, e leng se lokelang maemo ao maemo a mokelikeli a hlokang tekano pakeng tsa liphaephe tse ka holimo le tse ka tlase.

Mofokotsi oa Eccentric

Sefokotsi se Thibetseng

Di-reducer di bapala karolo ya phetoho tlhophisong ya diphaephe, di thusa ho fetola diphaephe ka boreledi pakeng tsa diphaephe tsa boholo bo fapaneng. Ntlafatso ena e ntlafatsa bokgoni le tshebetso ya sistimi ka kakaretso.

Setsoe:

Setsoe sa phaephe ea tšepe se na le karolo ea bohlokoa ka har'a litsamaiso tsa liphaephe, se thusa ho fetola tsela eo mokelikeli o phallang ka eona. E sebelisoa liphaepheng tse hokahanyang tsa bophara bo tšoanang kapa bo fapaneng, e leng se tataisang phallo ka katleho litseleng tse lakatsehang.

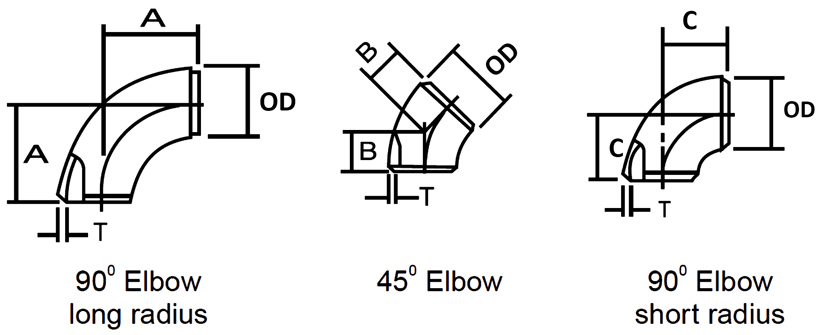

Li-elbow li arotsoe ka lihlopha ho latela tekanyo ea phetoho ea tataiso ea mokelikeli eo li e kenyang liphaepheng. Li-angle tse atisang ho kopana li kenyelletsa likhato tse 45, likhato tse 90 le likhato tse 180. Bakeng sa lits'ebetso tse ikhethileng, li-angle tse kang likhato tse 60 le likhato tse 120 lia sebetsa.

Litsoe li arotsoe ka lihlopha tse fapaneng ho latela radius ea tsona ha li bapisoa le bophara ba phaephe. Setsoe se Sekhutšoanyane sa Radius (SR setsoe) se na le radius e lekanang le bophara ba phaephe, e leng se etsang hore e lokele liphaephe tse nang le khatello e tlase, tse lebelo le tlase, kapa libaka tse koetsoeng moo sebaka se leng sa bohlokoa. Ka lehlakoreng le leng, Setsoe se Selele sa Radius (LR setsoe), se nang le radius e fetang bophara ba phaephe ka makhetlo a 1.5, se sebelisoa liphaepheng tse nang le khatello e phahameng le tse phallang ka sekhahla se phahameng.

Li-elbow li ka aroloa ka lihlopha ho latela mekhoa ea tsona ea ho hokahanya liphaephe—Se-elbow se Welded Butt, Se-elbow se Welded Socket, le Se-elbow se Threaded. Mefuta ena e fana ka ho tenyetseha ho latela mofuta oa manonyeletso o sebelisoang. Mabapi le thepa, li-elbow li entsoe ka tšepe e sa hloekang, tšepe ea khabone, kapa tšepe ea alloy, e ikamahanyang le litlhoko tse itseng tsa 'mele oa valve.

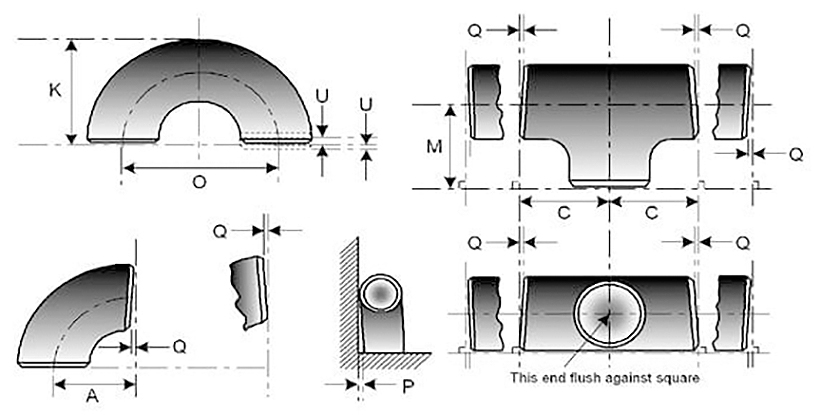

Tee:

Mefuta ea Tee ea Pipe ea Tšepe:

● Ho latela bophara le mesebetsi ea makala:

● Tee e lekanang

● Tee e Fokotsang (Tee e Fokotsang)

Ho ipapisitsoe le Mefuta ea Khokahano:

● Tee ea ho Weld Butt

● Tee ea ho Weld Socket

● Tee e nang le khoele

Ho ipapisitsoe le Mefuta ea Lintho:

● Tee ea Pipe ea Tšepe ea Khabone

● Tee ea Tšepe e kopantsoeng

● Tee ea Tšepe e sa Hloekeng

Dikopo tsa Tee ea Pipe ea Tšepe:

● Li-tee tsa tšepe tsa liphaephe ke lisebelisoa tse feto-fetohang tse fumanang lits'ebetso liindastering tse fapaneng ka lebaka la bokhoni ba tsona ba ho hokela le ho tsamaisa phallo ka litsela tse fapaneng. Tse ling tsa lits'ebetso tse tloaelehileng li kenyelletsa:

● Phetisetso ea Oli le Khase: Li-Tee li sebelisoa ho arola liphaephe bakeng sa ho tsamaisa oli le khase.

● Ho Hloekisa Petroleum le Oli: Libakeng tsa ho hloekisa, li-tee li thusa ho laola phallo ea lihlahisoa tse fapaneng nakong ea lits'ebetso tsa ho hloekisa.

● Mekhoa ea ho Phekola Metsi: Li-tee li sebelisoa lifemeng tsa ho phekola metsi ho laola phallo ea metsi le lik'hemik'hale.

● Liindasteri tsa Lik'hemik'hale: Li-tee li bapala karolo ts'ebetsong ea lik'hemik'hale ka ho tataisa phallo ea lik'hemik'hale le lintho tse fapaneng.

● Liphaephe tsa Bohloeki: Liindastering tsa lijo, tsa meriana le tse ling, liphaephe tsa bohloeki li thusa ho boloka maemo a bohloeki ha metsi a tsamaisoa.

● Liteishene tsa Motlakase: Li-Tee li sebelisoa litsamaisong tsa tlhahiso ea motlakase le kabo.

● Mechini le Lisebelisoa: Li-Tee li kopantsoe mechineng le lisebelisoa tse fapaneng tsa indasteri bakeng sa taolo ea mokelikeli.

● Li-Heat Exchanger: Li-Tee li sebelisoa litsamaisong tsa ho fapanyetsana mocheso ho laola phallo ea metsi a chesang le a batang.

Li-tee tsa tšepe tsa liphaephe ke likarolo tsa bohlokoa lits'ebetsong tse ngata, tse fanang ka ho tenyetseha le taolo holim'a kabo le tataiso ea maro. Khetho ea thepa le mofuta oa tee e itšetlehile ka lintlha tse kang mofuta oa mokelikeli o tsamaisoang, khatello, mocheso le litlhoko tse ikhethileng tsa ts'ebeliso.

Kakaretso ea Sekoahelo sa Pipe ea Tšepe

Sekwahelo sa phaephe ya tshepe, seo hape se bitswang polaka ya tshepe, ke sekwahelo se sebediswang ho kwahela pheletso ya phaephe. Se ka hokellwa pheletsong ya phaephe kapa sa hokelwa khoeleng ya kantle ya phaephe. Dikwahelo tsa phaephe ya tshepe di sebeletsa morero wa ho kwahela le ho sireletsa dikwahelo tsa phaephe. Dikwahelo tsena di tla ka dibopeho tse fapaneng, ho kenyeletswa dikwahelo tsa hemispherical, elliptical, dish, le circular.

Libopeho tsa Likhapete tse Konkonopo:

● Sekoahelo sa Hemisphere

● Sekoahelo sa elliptical

● Sekoahelo sa Dijana

● Sekoahelo se chitja

Mekhoa ea ho phekola khokahano:

Li-cap li sebelisoa ho khaola liphetoho le likhokahano liphaepheng. Khetho ea kalafo ea khokahano e itšetlehile ka litlhoko tse khethehileng tsa ts'ebeliso:

● Khokahano ea ho Weld ea Butt

● Khokahano ea ho Weld ea Socket

● Khokahano e nang le khoele

Likopo:

Li-end cap li na le mefuta e mengata ea ts'ebeliso ho pholletsa le liindasteri tse kang lik'hemik'hale, kaho, pampiri, samente le kaho ea likepe. Li bohlokoa haholo bakeng sa ho hokahanya liphaephe tsa bophara bo fapaneng le ho fana ka tšireletso pheletsong ea phaephe.

Mefuta ea Sekoahelo sa Pipe ea Tšepe:

Mefuta ea Khokahano:

● Sekoahelo sa ho Weld Butt

● Sekoahelo sa ho Weld sa Socket

● Mefuta ea Lintho:

● Sekwahelo sa Pipe ea Tšepe ea Khabone

● Sekoahelo sa Tšepe e sa Hloekeng

● Sekoahelo sa Tšepe ea Alloy

Kakaretso ea Kobeho ea Pipe ea Tšepe

Ho kobeha ha phaephe ya tshepe ke mofuta wa ho kenya phaephe ho sebediswang ho fetola tsela eo phaephe e tsamayang ka yona. Le hoja ho tshwana le setsoe sa phaephe, ho kobeha ha phaephe ho telele mme hangata ho etswa bakeng sa ditlhoko tse itseng. Ho kobeha ha phaephe ho tla ka boholo bo fapaneng, ka maemo a fapaneng a ho kobeha, ho dumella dikhutlo tse fapaneng tsa ho reteleha ha diphaephe.

Mefuta ea ho kobeha le Bokgoni:

Kobeho ea 3D: Kobeho e nang le radius e fetang bophara ba phaephe ka makhetlo a mararo. E sebelisoa hangata liphaepheng tse telele ka lebaka la ho kobeha ha eona ho bonolo le phetoho e sebetsang hantle ea tataiso.

Kobeho ea 5D: Kobeho ena e na le radius e fetang bophara ba phaephe ka makhetlo a mahlano. E fana ka phetoho e boreleli lehlakoreng, e leng se etsang hore e lokele liphaephe tse atolositsoeng ha ka nako e ts'oanang e boloka ts'ebetso ea phallo ea mokelikeli.

Ho lefella Liphetoho tsa Degree:

Kobeho ea 6D le 8D: Likobeho tsena, tse nang le radii ka makhetlo a tšeletseng le makhetlo a robeli ho feta bophara ba phaephe e tloaelehileng ka ho latellana, li sebelisetsoa ho buseletsa liphetoho tse nyane tseleng ea phaephe. Li netefatsa phetoho e butle-butle ntle le ho sitisa phallo.

Lipeipi tsa tšepe tse kobehileng ke likarolo tsa bohlokoa litsamaisong tsa lipeipi, tse lumellang liphetoho tse shebaneng le tsela ntle le ho baka pherekano e feteletseng kapa khanyetso phallong ea mokelikeli. Khetho ea mofuta oa kobehileng e itšetlehile ka litlhoko tse ikhethileng tsa phaephe, ho kenyeletsoa tekanyo ea phetoho lehlakoreng, sebaka se fumanehang, le tlhoko ea ho boloka litšobotsi tse sebetsang hantle tsa phallo.

Litlhaloso

| ASME B16.9: Tšepe ea Khabone, Tšepe e sa Ruseng, Tšepe e kopantsoeng |

| EN 10253-1: Tšepe ea Khabone, Tšepe e sa Ruseng, Tšepe e kopantsoeng |

| JIS B2311: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| DIN 2605: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| GB/T 12459: Tšepe ea Khabone, Tšepe e sa Ruseng, Tšepe e kopantsoeng |

Litekanyo tsa setsoe sa phaephe li koahetsoe ka ASME B16.9. Sheba tafole e fanoeng ka tlase bakeng sa boholo ba setsoe ho tloha ho 1/2″ ho isa ho 48″.

| Boholo ba Pipe bo Ikhethang | DIAMETER EA KANTLE | SETSI SA HO FELLA | ||

| Senthimithara. | OD | A | B | C |

| 1/2 | 21.3 | 38 | 16 | – |

| 3/4 | 26.7 | 38 | 19 | – |

| 1 | 33.4 | 38 | 22 | 25 |

| 1 1/4 | 42.2 | 48 | 25 | 32 |

| 1 1/2 | 48.3 | 57 | 29 | 38 |

| 2 | 60.3 | 76 | 35 | 51 |

| 2 1/2 | 73 | 95 | 44 | 64 |

| 3 | 88.9 | 114 | 51 | 76 |

| 3 1/2 | 101.6 | 133 | 57 | 89 |

| 4 | 114.3 | 152 | 64 | 102 |

| 5 | 141.3 | 190 | 79 | 127 |

| 6 | 168.3 | 229 | 95 | 152 |

| 8 | 219.1 | 305 | 127 | 203 |

| 10 | 273.1 | 381 | 159 | 254 |

| 12 | 323.9 | 457 | 190 | 305 |

| 14 | 355.6 | 533 | 222 | 356 |

| 16 | 406.4 | 610 | 254 | 406 |

| 18 | 457.2 | 686 | 286 | 457 |

| 20 | 508 | 762 | 318 | 508 |

| 22 | 559 | 838 | 343 | 559 |

| 24 | 610 | 914 | 381 | 610 |

| 26 | 660 | 991 | 406 | 660 |

| 28 | 711 | 1067 | 438 | 711 |

| 30 | 762 | 1143 | 470 | 762 |

| 32 | 813 | 1219 | 502 | 813 |

| 34 | 864 | 1295 | 533 | 864 |

| 36 | 914 | 1372 | 565 | 914 |

| 38 | 965 | 1448 | 600 | 965 |

| 40 | 1016 | 1524 | 632 | 1016 |

| 42 | 1067 | 1600 | 660 | 1067 |

| 44 | 1118 | 1676 | 695 | 1118 |

| 46 | 1168 | 1753 | 727 | 1168 |

| 48 | 1219 | 1829 | 759 | 1219 |

| Litekanyo tsohle li ka mm | ||||

Litekanyo tsa Liphaephe Mamello ho latela ASME B16.9

| Boholo ba Pipe bo Ikhethang | LITLHOKOMELISO TSOHLE | LITLHOKOMELISO TSOHLE | LITLHOKOMELISO TSOHLE | Litsoele le Li-Tee | LIKHETHO TSA HO KHUTLISA TSA DEG TSE 180 | LIKHETHO TSA HO KHUTLISA TSA DEG TSE 180 | LIKHETHO TSA HO KHUTLISA TSA DEG TSE 180 | LITHEKO TSA HO FOKOTSA |

LIKHETHE |

| NPS | OD ho Bevel (1), (2) | Boitsebiso Qetellong | Botenya ba Lebota (3) | Tekanyo ea Bohareng ho isa Qetellong A,B,C,M | Bohareng ho ea Bohareng O | K ea ho Khutlela Sefahlehong | Ho Lokisa Lipheletso U | Bolelele bo Akaretsang H | Bolelele ba Kakaretso E |

| ½ ho isa ho 2½ | 0.06 | 0.03 | Bonyane 87.5% ea botenya bo tloaelehileng | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 3 ho isa ho 3 ½ | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 4 | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 5 ho isa ho 8 | 0.09 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 | |

| 10 ho isa ho 18 | 0.16 | 0.12 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| 20 ho isa ho 24 | 0.25 | 0.19 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| 26 ho isa ho 30 | 0.25 | 0.19 | 0.12 | … | … | … | 0.19 | 0.38 | |

| 32 ho isa ho 48 | 0.25 | 0.19 | 0.19 | … | … | … | 0.19 | 0.38 |

| Boholo ba Phaephe bo Ikhethang NPS | MAMETLELELO A ANGULARITY | MAMETLELELO A ANGULARITY | Litekanyo Tsohle li Fanoa ka Li-inchi. Mamello ea lekana le ho feta 'me e ka tlase ntle le ha ho boletsoe. |

|

| Q e sa Tšoarellang | Kantle ho Sefofane P | (1) Kantle ho potoloho ke kakaretso ea boleng bo felletseng ba mamello ea ho eketsa le ho tlosa. (2) Mamello ena e kanna ea se sebetse libakeng tse fumanehang tsa li-fitting tse entsoeng moo botenya ba lebota bo eketsehileng bo hlokahalang ho fihlela litlhoko tsa moralo oa ASME B16.9. (3) Bophara ba kahare le botenya ba mabota a tloaelehileng lipheletsong li lokela ho hlalosoa ke moreki. (4) Ntle le ha moreki a boletse ka tsela e 'ngoe, mamello ena e sebetsa ho bophara ba kahare bo tloaelehileng, bo lekanang le phapang pakeng tsa bophara ba kantle bo tloaelehileng le botenya ba lebota bo habeli. |

| ½ ho isa ho 4 | 0.03 | 0.06 | |

| 5 ho isa ho 8 | 0.06 | 0.12 | |

| 10 ho isa ho 12 | 0.09 | 0.19 | |

| 14 ho isa ho 16 | 0.09 | 0.25 | |

| 18 ho isa ho 24 | 0.12 | 0.38 | |

| 26 ho isa ho 30 | 0.19 | 0.38 | |

| 32 ho isa ho 42 | 0.19 | 0.50 | |

| 44 ho isa ho 48 | 0.18 | 0.75 |

Maemo le Kereiti

| ASME B16.9: Lisebelisoa tsa ho Cheseletsa Li-Butt tse Entsoeng Femeng | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| EN 10253-1: Lisebelisoa tsa Liphaephe tsa ho Welding Butt-Welding - Karolo ea 1: Tšepe ea Khabone e Betliloeng bakeng sa Tšebeliso e Akaretsang le Ntle le Litlhoko tse Ikhethang tsa Tlhahlobo | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| JIS B2311: Lisebelisoa tsa Pipe ea ho Cheseletsa Mokokotlo oa Tšepe bakeng sa Tšebeliso e Tloaelehileng | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| DIN 2605: Lisebelisoa tsa Liphaephe tsa ho Cheseletsa Li-Butt tsa Tšepe: Li-Elbow le Li-Kobeho tse nang le Khatello e Fokolitsoeng | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

| GB/T 12459: Lisebelisoa tsa Pipe tse se nang Seamless tsa ho Welding Butt-Butt tsa Tšepe | Lisebelisoa: Tšepe ea Khabone, Tšepe e sa Hloekeng, Tšepe e kopantsoeng |

Mokhoa oa Tlhahiso

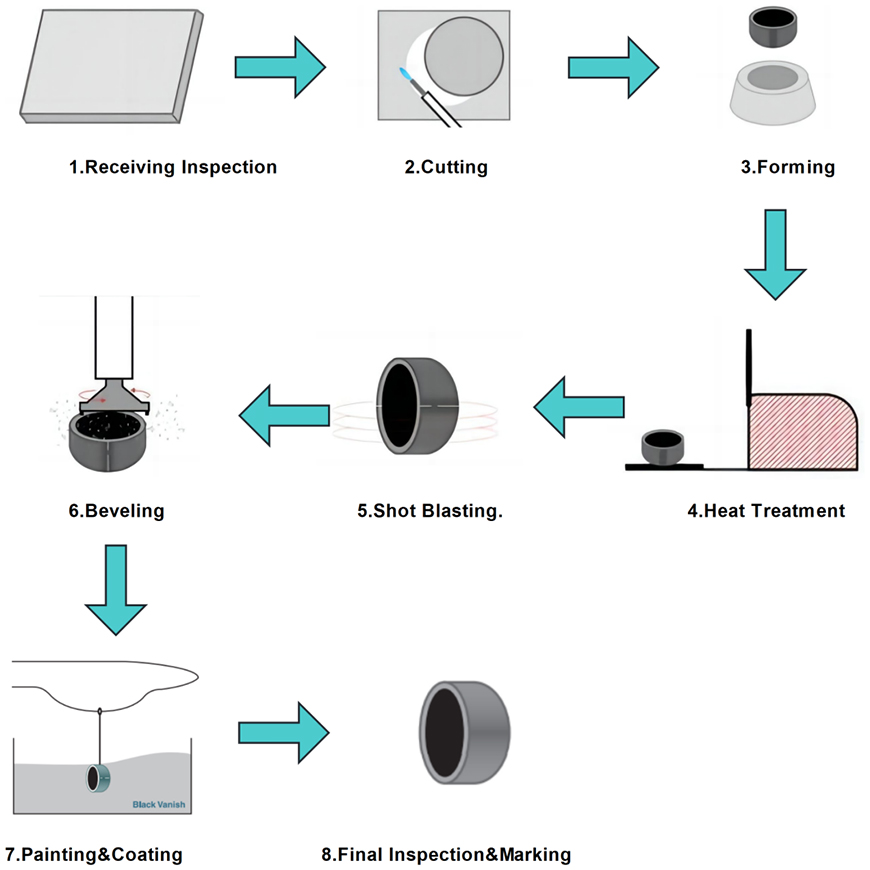

Mokhoa oa Tlhahiso ea Cap

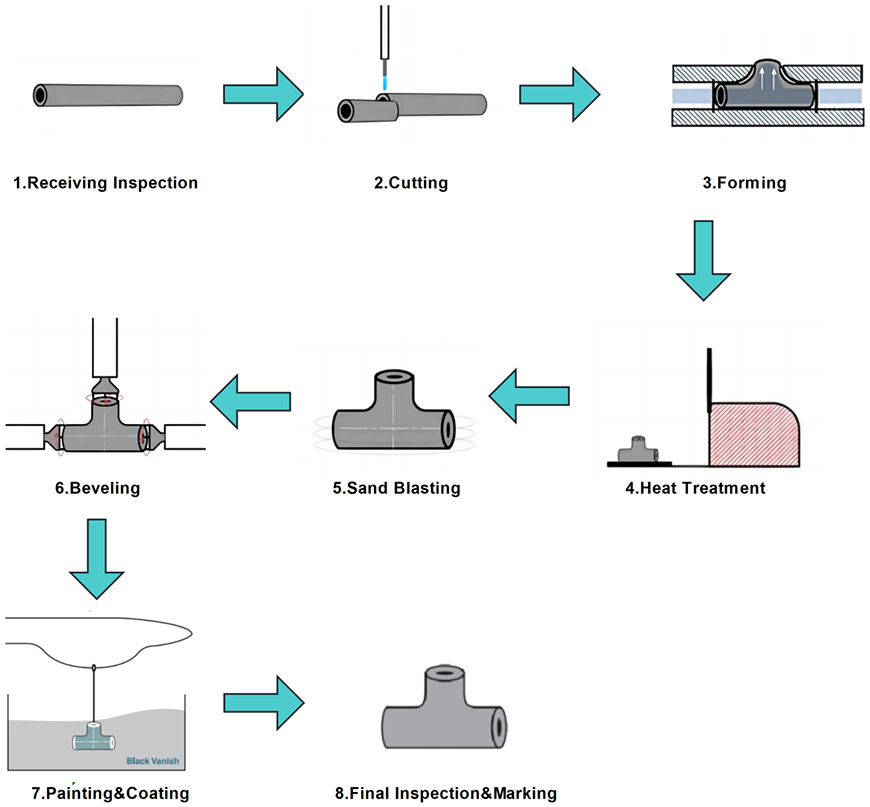

Mokhoa oa ho Etsa Li-Tee

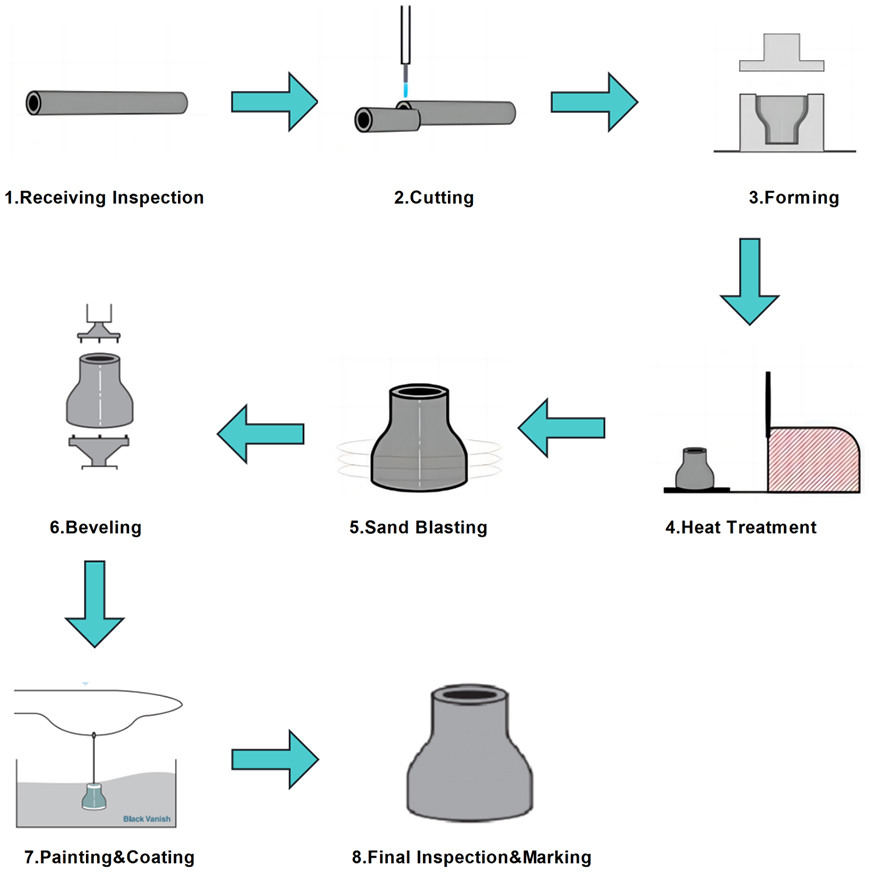

Mokhoa oa Tlhahiso ea ho Fokotsa

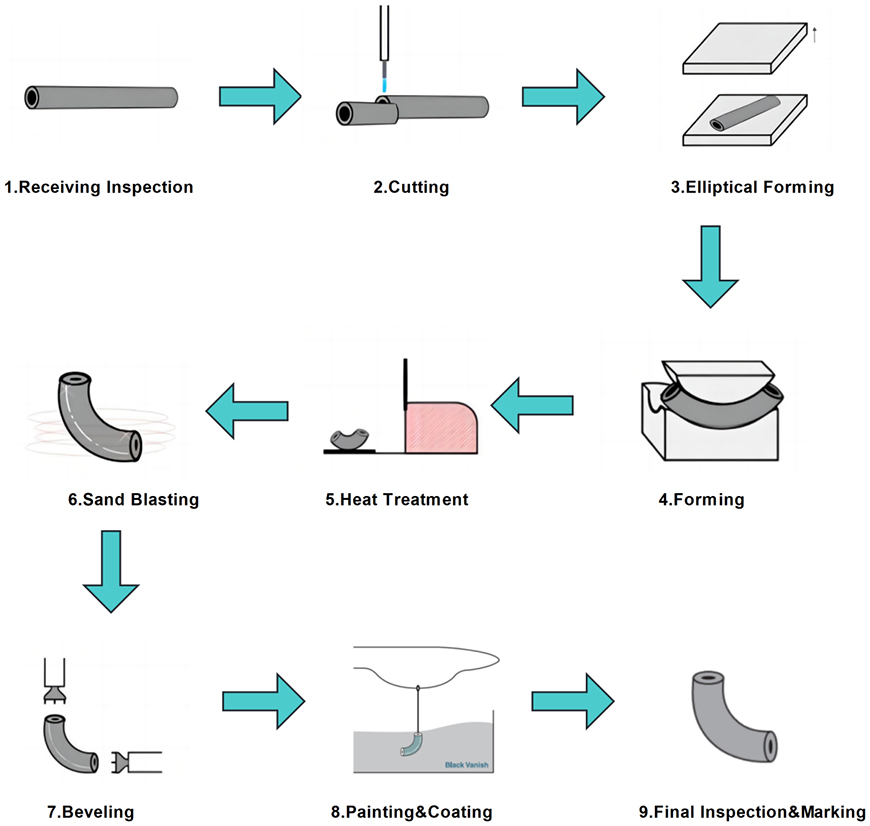

Mokhoa oa ho Etsa Litsoele

Taolo ea Boleng

Tlhahlobo ea Lisebelisoa tse Tala, Tlhahlobo ea Lik'hemik'hale, Teko ea Mekaniki, Tlhahlobo ea Pono, Tlhahlobo ea Tekanyo, Teko ea ho Kobeha, Teko ea ho Foforeha, Teko ea Tšusumetso, Teko ea DWT, Tlhahlobo e sa Senyeheng, Teko ea ho Tiea, Teko ea Khatello, Teko ea ho Dutla ha Litulo, Teko ea Ts'ebetso ea Phallo, Teko ea Torque le Thrust, Tlhahlobo ea ho Penta le ho Koahela, Tlhahlobo ea Litokomane…..

Tšebeliso le Tšebeliso

Tlhahlobo ea Lisebelisoa tse Tala, Tlhahlobo ea Lik'hemik'hale, Teko ea Mekaniki, Tlhahlobo ea Pono, Tlhahlobo ea Tekanyo, Teko ea ho Kobeha, Teko ea ho Foforeha, Teko ea Tšusumetso, Teko ea DWT, Tlhahlobo e sa Senyeheng, Teko ea ho Tiea, Teko ea Khatello, Teko ea ho Dutla ha Litulo, Teko ea Ts'ebetso ea Phallo, Teko ea Torque le Thrust, Tlhahlobo ea ho Penta le ho Koahela, Tlhahlobo ea Litokomane…..

● Khokahano

● Taolo ea tataiso

● Taolo ea Phallo

● Karohano ea Mecha ea Litaba

● Ho Kopanya Metsi

● Tšehetso le Tšehetso

● Taolo ea Mocheso

● Bohloeki le ho Hloka Bana

● Polokeho

● Lintho Tse Lokelang ho Etsoa ka Botle le Tikoloho

Ka bokhutšoanyane, li-fitting tsa liphaephe ke likarolo tsa bohlokoa tse nolofalletsang ho tsamaisoa ha maro le likhase ka katleho, ka mokhoa o sireletsehileng le o laoloang ho pholletsa le mefuta e mengata ea liindasteri. Litšebeliso tsa tsona tse fapaneng li tlatsetsa ho ts'epahaleng, ts'ebetsong le polokehong ea litsamaiso tsa ho sebetsana le maro maemong a mangata.

Ho paka le ho Romela

Ho Womic Steel, re utloisisa bohlokoa ba ho paka ka mokhoa o sireletsehileng le ho romela thepa ka mokhoa o tšepahalang ha ho tluoa tabeng ea ho tlisa liphaephe tsa rona tsa boleng bo holimo monyako oa hau. Mona ke kakaretso ea mekhoa ea rona ea ho paka le ho romella thepa bakeng sa litšupiso tsa hau:

Sephutheloana:

Lisebelisoa tsa rona tsa liphaephe li phuthetsoe ka hloko ho netefatsa hore li fihla ho uena li le boemong bo phethahetseng, li loketse litlhoko tsa hau tsa indasteri kapa tsa khoebo. Ts'ebetso ea rona ea ho paka e kenyelletsa mehato ea bohlokoa e latelang:

● Tlhahlobo ea Boleng: Pele ho liphutheloana, lisebelisoa tsohle tsa liphaephe li hlahlojoa ka botlalo ho netefatsa hore li fihlela litekanyetso tsa rona tse thata tsa ts'ebetso le botšepehi.

● Sekoahelo se Sireletsang: Ho latela mofuta oa thepa le ts'ebeliso, lisebelisoa tsa rona li ka fumana sekoahelo se sireletsang ho thibela ho bola le tšenyo nakong ea lipalangoang.

● Ho Kopanya ka Sireletsehileng: Li-fittings li kopanngoa hammoho ka mokhoa o sireletsehileng, ho netefatsa hore li lula li tsitsitse ebile li sirelelitsoe nakong eohle ea ts'ebetso ea ho romella.

● Ho Ngola le ho Fana ka Litokomane: Sephutheloana se seng le se seng se ngotswe ka ho hlaka ka tlhahisoleseding ya bohlokwa, ho kenyeletswa le ditlhaloso tsa sehlahiswa, bongata, le ditaelo dife kapa dife tse ikgethang tsa ho sebetsana le sona. Ditokomane tse amehang, tse kang disetifikeiti tsa ho latela melao, le tsona di a kenyeletswa.

● Sephutheloana se Ikhethileng: Re ka amohela likopo tse khethehileng tsa ho paka ho latela litlhoko tsa hau tse ikhethang, re netefatsa hore lisebelisoa tsa hau li lokisitsoe hantle kamoo ho hlokahalang.

Ho tsamaisa ka sekepe:

Re sebelisana 'moho le balekane ba tšepahalang ba ho romela thepa ho netefatsa hore thepa e tla romelloa ka mokhoa o tšepahalang le o nakong sebakeng seo u se boletseng. Sehlopha sa rona sa thepa se ntlafatsa litsela tsa ho romela thepa ho fokotsa linako tsa ho tsamaisa thepa le ho fokotsa kotsi ea tieho. Bakeng sa thepa ea machabeng, re sebetsana le litokomane tsohle tse hlokahalang tsa thepa ea lekgetho le ho latela melao ho nolofatsa ho tlosoa ha thepa ea lekgetho ka mokhoa o boreleli. Re fana ka likhetho tse feto-fetohang tsa ho romela thepa, ho kenyeletsoa le ho romelloa ka potlako bakeng sa litlhoko tse potlakileng.