Tlhaloso ea Sehlahisoa

Phaephe ea ho phunya e sebelisetsoang ho hokahanya lisebelisoa tsa bokaholimo ba rig ea ho phunya le lisebelisoa tsa ho sila kapa tsa ho phunya, ke phaephe ea tšepe e nang le lipheletso tsa khoele, hape e etsa khokahano ea lisebelisoa tsa lesoba le ka tlase la ho phunya. Phaephe ea ho phunya hangata e arotsoe ka kelly, phaephe ea ho phunya le phaephe ea ho phunya e boima. Liphaephe tsa ho phunya tsa tšepe li tla ka boholo bo fapaneng, matla le botenya ba lebota, empa hangata li bolelele ba limithara tse 27 ho isa ho tse 32 (Sebaka sa 2). Ho na le bolelele bo bolelele, ho fihlela maotong a 45 (Sebaka sa 3).

Khola ea ho phunya ke karolo e ka sehloohong ea sesebelisoa sa ho phunya se ka tlase, e sebetsoa botlaaseng ba khoele ea ho phunya. Botenya ba khola ea ho phunya bo boholo, hape le matla a khoheli le ho tiea ho hoholo. Ho ntlafatsa mosebetsi oa ho khopama, ho sebetsana le li-groove tsa lifti le li-groove tse thellang holim'a khoele e ka hare ea khola ea ho phunya e ka ba khetho e ntle. Likhola tsa ho phunya tse potolohang, likhola tsa ho phunya tse kopaneng. le likhola tsa ho phunya tse seng tsa makenete ke likhola tsa ho phunya tse ka sehloohong 'marakeng.

Litlhaloso

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210 :S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Kreiti ya 1, Kreiti ya 3, Kreiti ya 4, Kreiti ya 6, Kreiti ya 7, Kreiti ya 8, Kreiti ya 9. Kreiti ya 10, Kreiti ya 11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1 : P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163 :10#,20#,Q345 |

| GB/T 8162 :10#,20#,35#,45#,Q345 |

Maemo le Kereiti

Liphaephe tsa ho Cheka Mekhahlelo e Tloaelehileng:

API 5DP, API Spec 7-1 E75,X95,G105 jj...

Mefuta ea Khokahano: FH, IF, NC, REG

Mefuta ea Khoele: NC26,NC31,NC38,NC40,NC46,NC50,5.1/2FH

Lisebelisoa: Tšepe ea k'habone/Tšepe e sa hloekang/Tšepe e kopantsoeng

Phaephe ea ho tjheka e lokela ho tlisoa ho latela likhokahano tse kaholimo le maemo a API5CT / API Standards.

Taolo ea Boleng

Tlhahlobo ea Lisebelisoa tse Tala, Tlhahlobo ea Lik'hemik'hale, Teko ea Mechanical, Tlhahlobo ea Pono, Teko ea Khatello, Tlhahlobo ea Tekanyo, Teko ea Kobeha, Teko ea ho Fokotsa, Teko ea Tšusumetso, Teko ea DWT, Teko ea NDT, Teko ea Hydrostatic, Teko ea ho Tiea…..

Ho tšoaea, ho penta pele ho pepa.

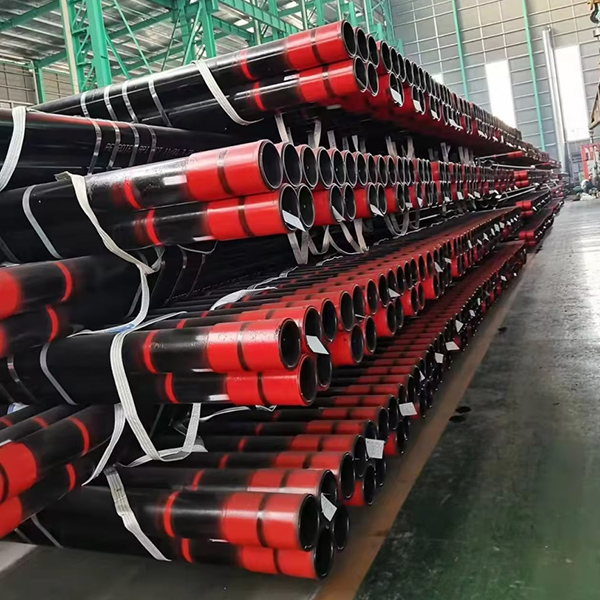

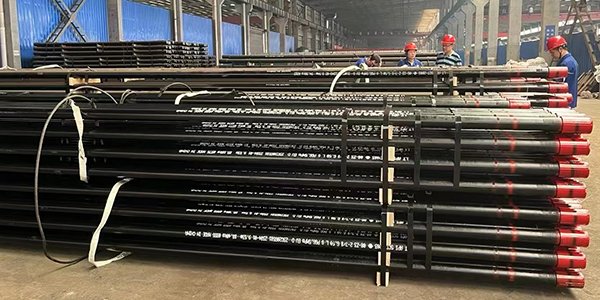

Ho paka le ho Romela

Mokhoa oa ho paka liphaephe tsa tšepe o kenyelletsa ho hloekisa, ho li hlopha ka lihlopha, ho li phuthela, ho li kopanya, ho li tiisa, ho li ngola, ho li kenya ka har'a liphaephe (haeba ho hlokahala), ho li kenya ka har'a lijana, ho li beha ka har'a liphaephe, ho li koala, ho li tsamaisa le ho li pakolla. Mefuta e fapaneng ea liphaephe tsa tšepe le li-fittings tse nang le mekhoa e fapaneng ea ho li paka. Ts'ebetso ena e felletseng e netefatsa hore liphaephe tsa tšepe lia romelloa le ho fihla moo li eang teng li le boemong bo botle, li loketse ts'ebeliso ea tsona e reriloeng.

Tšebeliso le Tšebeliso

Liphaephe tsa tšepe li sebetsa e le mokokotlo oa boenjiniere ba indasteri le ba sechaba ba sejoale-joale, li tšehetsa mefuta e mengata ea lits'ebetso tse tlatsetsang nts'etsopele ea lichaba le moruo lefatšeng ka bophara.

Liphaephe tsa tšepe le lisebelisoa tseo re li hlahisitseng Womic Steel li sebelisoa haholo bakeng sa peterole, khase, mafura le liphaephe tsa metsi, liphaephe tsa leoatle le tsa kaho, ho cheka, merero ea kaho ea tšepe, ho bokella le borokho, hape le liphaephe tsa tšepe tse nepahetseng bakeng sa tlhahiso ea li-roller tsa conveyor, jj.